£10M Tech Upgrade Spurs Growth in Engineering Firm

Where creativity bears fruit

Growing value through innovation since 2012, Polar Technology Management Group is benefitting from a new £10 million facility as it looks to remain at the leading edge of the advanced engineering market

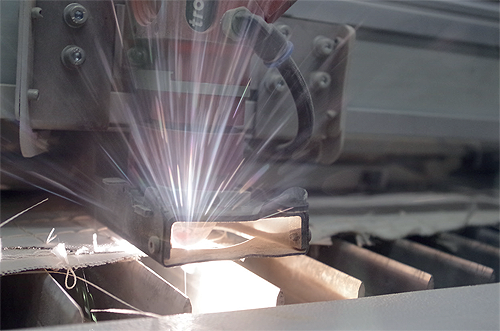

Between 2012, when the company was founded, and 2019, Polar Technology Management Group enjoyed rapid growth, building a strong, balanced portfolio in the aerospace, defense, medical and motor sport sectors. An expert in advanced engineering technologies, the company operates under two brand names – SST Technology, which designs and manufactures advanced fabrications, including tubular components, ducting and high-performance insulation, and Lentus Composites, which designs and manufactures a broad portfolio of complex composite components.

Polar’s well-renowned capabilities have allowed it to attract a customer base consisting of distinguished global brands. One key area in which the company has been supporting these clients of late is in its drive to achieve net zero carbon status within the next 10-to-20 years.

“Low carbon targets are important for almost every business out there at the moment, so we have been focusing on developing technologies that can help them achieve that,” explains Chairman & Joint Founding Partner Scott Roberts. “For example, for one of our clients, we are looking at replacing the carbon fiber used in their racing cars with flax-reinforced polymers, which will eliminate the huge energy consumption of the carbon fiber manufacturing process and replace it with a natural product that can actually absorb CO2 during the growth of the plant.

“It’s funny,” Scott adds. “People think that racing cars are big polluters, but actually, with the technology we are developing and helping our clients utilise, motor racing is becoming one of the cleanest sports around.”

Not just interested in boosting the sustainability credentials of its customers, Polar is also taking steps to decrease its own impact on the environment. The company’s new state-of-the-art, 100,000-square-foot facility, for instance, boasts a number of green features designed to eliminate the vast majority of Polar’s carbon footprint. A £10 million site, the new factory sits alongside an old facility built in the 1980s that was highly inefficient in comparison.

“Our new factory has got all the latest methods of heating, cooling and air exchange, as well as a selection of modern processes,” Scott says. “The new ovens installed on-site contain components designed to clean waste gas and we have also replaced a host of power-hungry machines with new equipment designed to use less power. It’s not only great for the environment, but it’s great for us too because the changes have helped knock thousands of pounds off our energy bills.”

By combining activities associated with composite materials and high-end metal alloys, Polar is able to deliver a suite of innovative products for its customers, including MRI scanner components and complex exhaust systems for Formula One vehicles. Never short of opportunities thanks to its track record of technical excellence, Polar generally works with large global firms where its specialist manufacturing is scalable.

“We usually start off at low-rate production and then we can think about what we need to do to scale up so that the price for the customer and cost of production is only going to come down,” Scott reports. “As part of this strategy, we design the manufacturing process so that it delivers a product the customer wants, but also a product that can be transitioned into a scalable market. Even with something that sounds very niche, like pipework or a heat exchanger on a racing car, that technology can be taken into the wider specialist vehicle market.”

Understandably, for such an ideas-based business, intellectual property is a critical part of Polar’s work. As an organisation determined to drive sustainable growth and increase shareholder value, Polar prioritises the creation and protection of market-leading technologies that allow it to remain competitive on the global stage.

Understandably, for such an ideas-based business, intellectual property is a critical part of Polar’s work. As an organisation determined to drive sustainable growth and increase shareholder value, Polar prioritises the creation and protection of market-leading technologies that allow it to remain competitive on the global stage.

“It might start with a good idea that you produce in low volume for a racing car,” Scott remarks. “That is where you develop your initial IP and test concept. Following that, you might move into more mid-volume production as you prove the success of that intellectual property, make sure the design is perfect for production and decide on what you want to patent. Finally, you move into high-rate production, where big global businesses might become interested, but you hold the IP and so can suggest putting it into an escrow account in order to profit from it, while eliminating risk. Protecting and exploiting intellectual property through every part of the journey is how you grow an engineering business like ours.”

Strengthened by the principles and procedures Scott relates, Polar has been able to survive the Covid-19 pandemic, turning a small profit in the process. As vaccination programs roll out across the world, the company now hopes to re-focus its energies on growth, with a particular emphasis on doubling its turnover to £30 million in the next 24 to 36 months.

“We know exactly what we are going to do, who we are going to do it with, how we are going to do it and what resources we need in terms of people, materials and machines,” Scott asserts. “Getting from £16 million to £30 million in the next two to three years won’t be easy, but I think we can do it. We have six or seven products that have already been signed off by our customers and they will soon be going into volume production for large global companies.”

In April 2021, the Business Growth Fund invested £10 million in Polar to support the company’s ambitious plans. The funding will not only offer the firm more financial security during what has been a turbulent period for many businesses, but it will also allow Polar to concentrate on profitable growth.

“We are collaborating with universities – us doing the manufacturing and engineering, and the universities putting in a bit of science and technology knowhow – and we are working in partnership with end users to come up with the next generation of technology and solutions that could set us on a trajectory towards £40 million or £50 million turnover within five years,” Scott declares. “It’s not an unrealistic target, just the result of real-world business and feet-on-the-ground aspirations. Of course, it’s not going to be easy, but we have got the opportunity to accelerate our organic growth with more working capital and we are also pursuing some really interesting strategic acquisitions.

“Even then, without the support of a passionate, skilled and dedicated workforce present throughout every area of the business, none of our ambitions could be realised. So, this success story is really for them!”

Polar Technology Management Group

www.polartechnology.co.uk

Products: Advanced fabrications and composite products