6K Inc’s MIT-born plasma reactor is singlehandedly solving battery manufacturing’s waste issue

In the realm of chemistry, 6K Inc (6K) is pushing boundaries by developing engineered materials for revolutionary products. These will advance industries including additive manufacturing, renewable energy, aerospace, consumer electronics, and more. Leveraging advanced microwave plasma technology and sustainable processes, the company empowers its clients to bring their innovations to life at unprecedented speeds. Sam Trinch, President of 6K Energy, the division manufacturing lithium-ion battery material for energy storage, mobility and electric vehicles, provides a technical overview of 6K’s main technology.

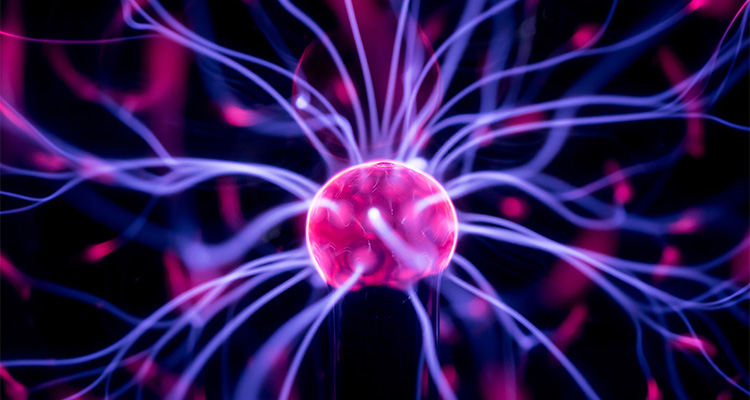

“At the core of our technology, developed at the MIT Plasma Science and Fusion Center, is our utilization of microwave-based plasma. We use an off-the-shelf microwave generator to generate a highly efficient standing wave on top of our proprietary UniMelt® reactor, a structure measuring four feet in diameter and standing at 15 feet tall, manufactured in America. Into this, we then insert gas and a proprietary torch, which is a specialized metal rod combined with gas and microwave energy. This process results in the formation of a plasma ball, typically four-to-five inches in diameter and reaching a temperature of 6000° Kelvin, hence our company name, 6K. Given that this temperature is the same as that of the sun and unsuitable for practical use, our scientists have invented a method to change the temperature of the ball by introducing gas flows. This adjustment facilitates the creation of a large, homogenous production zone within the gas environment. Furthermore, we have precise control over the temperature in this homogenous production zone, allowing the production of battery material that would otherwise burn,” he begins.

“At the core of our technology, developed at the MIT Plasma Science and Fusion Center, is our utilization of microwave-based plasma. We use an off-the-shelf microwave generator to generate a highly efficient standing wave on top of our proprietary UniMelt® reactor, a structure measuring four feet in diameter and standing at 15 feet tall, manufactured in America. Into this, we then insert gas and a proprietary torch, which is a specialized metal rod combined with gas and microwave energy. This process results in the formation of a plasma ball, typically four-to-five inches in diameter and reaching a temperature of 6000° Kelvin, hence our company name, 6K. Given that this temperature is the same as that of the sun and unsuitable for practical use, our scientists have invented a method to change the temperature of the ball by introducing gas flows. This adjustment facilitates the creation of a large, homogenous production zone within the gas environment. Furthermore, we have precise control over the temperature in this homogenous production zone, allowing the production of battery material that would otherwise burn,” he begins.

For battery material, this process is used to synthesize chemical elements and control particle size and microstructure to produce advanced battery material at a fraction of the time and cost as conventional processes.

6K’s ingenious microwave plasma technology is also useful in the production of additive manufacturing materials, as Sam explains. “We operate another business unit that applies the same technology for producing additive manufacturing materials, focusing on the chemistry of pure metals. This unit possesses intellectual property enabling the conversion of scrap materials, such as scrap titanium, nickel and refractory metals, into a pure premium powder state. The process involves milling the material to a specific volume, introducing it into the plasma in a solid state, controlling the temperature, and utilizing surface tension to form a ball of metal powder consisting of nickel, titanium, copper, tungsten, C-103/niobium, Inconel, or superalloys, which are subsequently employed in the additive manufacturing processes. Due to its spherical shape, the resulting material flows smoothly and efficiently, contrasting with traditional cold plasma methods where temperature control and consistency are challenging. Our controlled process ensures high yields and minimal waste as everything enters and exits the system at the correct volume, allowing for reprocessing of any flawed materials. The mantra for our additive team is – we take nothing from the ground, and we put nothing into the ground. For battery materials, we have the flexibility to introduce solids for atom manufacturing, liquid for products like Lithium nickel manganese cobalt oxides (NMC), or slurries that can be processed into powders within the plasma environment. Essentially, our operations revolve around efficiency, optimization of the battery materials manufacturing process, and waste reduction.”

Indeed, 6K’s technology was developed with sustainability in mind, which means it tremendously minimizes waste and energy consumption compared to traditional processes. “To make NMC products, metals like nickel, cobalt, manganese are washed and dried to diffuse with lithium, a process demanding substantial energy and creating significant sodium sulphate waste. Conventional methods involve prolonged high-temperature mixing and washing, leading to the generation of 30-to-34 kilograms of sodium sulphate waste per kilogram of powder. This waste is often disposed of in large bodies of water or boiled down into a sludge of four kilograms through energy-intensive processes and sent to landfill. In contrast, our process bypasses these steps by directly utilizing a precursor material that we put into the plasma as a liquid-water mixture. We then remove the water within two seconds before controlling the plasma’s temperature, as it is a highly reactive environment where ions form crystals of nickel, cobalt, manganese, and lithium in less than a second. Following this rapid crystallization, we make minor adjustments to form the structure and proceed with deagglomeration through milling. Consequently, a process that typically takes three-to-four days, is condensed into only a few hours without creating any waste. Despite generating nitrous oxide gas as a byproduct, we capture the NOx in its entirety and scrub it. Interestingly enough, the gas output mirrors the input concentration, resembling the process of nitric acid creation. By integrating this gas back into a nitrogen generation system to produce nitric acid, our approach remains fully circular and waste-free,” Sam elaborates.

Thanks to this eco-friendlier process that consumes less energy and water while generating no waste, NMC manufacturing locally in the US is cheaper than it would be overseas in countries like China or Korea. According to Sam, this approach and its benefits also extend to 6K Energy’s lithium iron phosphate battery (LFP) manufacturing. “While we can produce LFP using this plasma method, we need to slightly refine the process to ensure proper carbon coating on the structure for conductivity. Nonetheless, we can also manufacture it following the traditional method due to our expertise in North America. My team members and I have been making LFP for decades, starting our work at MIT in 2001, well before this chemistry gained recognition, and we launched it in North America. Between 2011 and 2015, we shipped millions of cells built in North America to China. We’ve initially opted for the conventional process, reserving the next two years for transitioning to plasma technology, which is more cost-efficient. While China may offer cheaper alternatives, our shift towards domestic production reduces reliance on foreign sources for critical materials and allows us to maintain competitiveness by avoiding customs-related issues or challenges like port delays in the supply chain.

“Recently, we publicly announced a large agreement to produce our LFP batteries in North America for Gotion Incorporated (Gotion North America), the third largest LFP manufacturer in the world, who selected our North American production process, knowing that we can deliver competitively. When Gotion needed to vet the specifics of our operations, we provided a comprehensive breakdown of every piece of equipment, the time it takes to run it, labor requirements, energy consumption, associated costs, our hourly rates, and negotiated electricity rates at our facility. This approach is how we define our manufacturing expenses when engaging with customers, enabling us to tailor quotes to meet their specific pricing needs,” Sam ends.

With its pioneering microwave plasma technology, 6K launches a new era of sustainable and efficient materials manufacturing, thus empowering clients across industries to rapidly realize their innovative visions while minimizing their environmental impact.