7 Key Uses of Additive Manufacturing Driving Innovation in the Next Decade

What Is Additive Manufacturing?

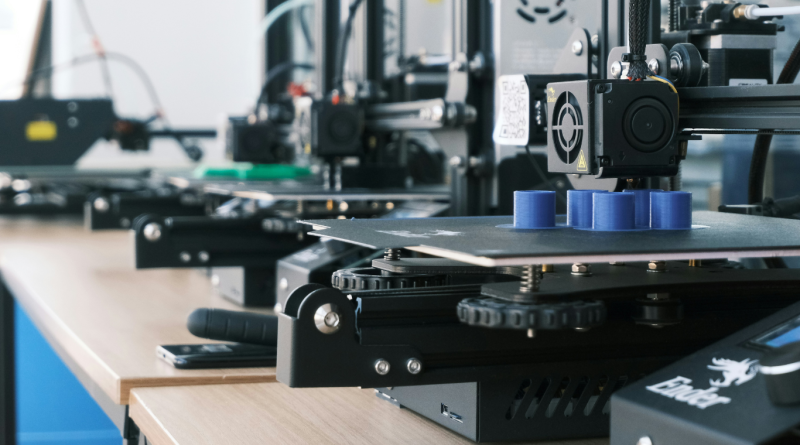

Additive manufacturing, often referred to as 3D printing, is a process in which objects are built by adding material layer by layer. Unlike traditional manufacturing methods that rely on subtracting material from a larger block (such as cutting or drilling), additive manufacturing allows for high precision, material efficiency, and the creation of complex geometries. The process is revolutionizing industries by reducing costs, speeding up production, and offering more sustainable practices.

Below are the top 7 uses of 3D printing that are shaping the future.

1. Healthcare and Bioprinting

Additive manufacturing is transforming healthcare by enabling the production of customized prosthetics, medical implants, and even bioprinted tissues. These 3D-printed medical devices are tailored to the unique anatomy of each patient, improving fit and function. Researchers are also exploring bioprinting techniques that may one day allow the creation of functional human organs, potentially solving global organ shortages.

2. Aerospace and Defense

In aerospace and defense, additive manufacturing is used to produce lightweight, high-strength parts that are critical for aircraft and military equipment. Companies like Boeing and Airbus have adopted 3D printing to create fuel-efficient components, while defense sectors benefit from the ability to produce parts on demand, reducing supply chain delays and material waste.

3. Automotive Industry

The automotive sector is utilizing 3D printing for rapid prototyping, custom part production, and innovative vehicle designs. Electric vehicle manufacturers use additive manufacturing to create lightweight, efficient parts, while companies like BMW are 3D printing complex structures that were once too expensive or time-consuming to produce traditionally.

4. Construction and Architecture

In construction, additive manufacturing allows for the 3D printing of buildings and infrastructure components, reducing construction time and material waste. Entire homes and offices can be printed in a matter of days. Companies like ICON are leading the way with 3D-printed homes that offer affordable, sustainable housing solutions.

5. Consumer Goods and Customization

Additive manufacturing is revolutionizing consumer goods by enabling mass customization. From personalized footwear and eyewear to bespoke electronics, 3D printing allows manufacturers to cater to individual preferences. This approach reduces overproduction and waste while offering consumers the opportunity to co-create designs that fit their needs.

6. Energy Sector

The energy industry is using 3D printing to optimize the design of renewable energy systems, such as wind turbines and solar panels. Additive manufacturing reduces material waste while improving energy efficiency, particularly in the creation of components for wind and hydropower systems, making clean energy more cost-effective and scalable.

7. Electronics and Wearable Devices

In the electronics industry, 3D printing is enabling the production of miniaturized and flexible devices such as wearable technology, sensors, and IoT systems. This process allows for the integration of multiple functions into a single compact device. The potential for fully 3D-printed circuits and electronics is expanding the possibilities for smart wearables and advanced tech applications.

Additive manufacturing is far more than just a trend; it’s reshaping the way industries approach design, production, and sustainability. From healthcare advancements to energy innovation, additive manufacturing opens doors to customization, efficiency, and reduced environmental impact.