LS Cable’s $99M U.S. Subsea Cable Factory

The recent announcement of a $99 million investment by LS Cable & System, supported by the U.S. Department of Energy, marks a significant milestone in the United States’ renewable energy sector. This substantial financial infusion, allocated through the Inflation Reduction Act of 2022 under Section 48C, aims to establish a state-of-the-art subsea cable manufacturing facility by LS GreenLink USA, a wholly-owned subsidiary of the South Korean industrial giant.

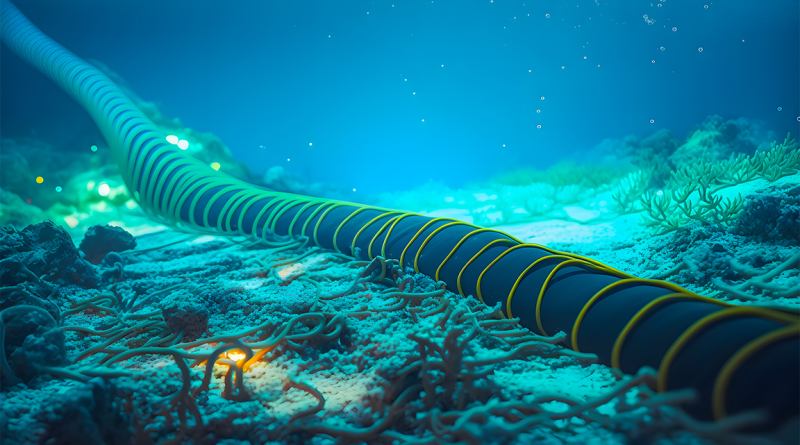

LS GreenLink USA’s strategic initiative involves constructing a high-voltage submarine power cable factory poised to bolster the U.S. position in global energy markets. This move is not just about enhancing manufacturing capabilities but also about aligning with the U.S. government’s clean energy goals, which emphasize innovation and sustainability in the energy sector. The facility is set to produce vital components essential for connecting offshore wind farms to the power grid, addressing a crucial link in the renewable energy supply chain.

The new factory’s manufacturing capabilities are geared towards producing high-voltage submarine power cables capable of withstanding extreme underwater conditions, which are critical for the transmission of energy from offshore wind farms to mainland power networks. With plans to produce cables up to 525kV HVDC and 400kV HVAC, the facility promises to cover the full spectrum of needs for offshore wind projects and other subsea interconnections.

Technologically, the facility is designed to be at the forefront of the subsea cable industry, equipped with the latest in cable manufacturing technology. This includes advanced materials science applications and innovations in cable design that enhance efficiency and reliability. The introduction of such high-specification products is expected to set new industry standards and propel the U.S. into a leadership role in the global renewable energy technology arena.

Creating Jobs and Boosting Local Economies

The establishment of the subsea cable manufacturing facility is not just a technological achievement but also a significant economic boon for the local area. The factory is projected to create over 200 direct new jobs by the end of its first phase, with many more indirect job opportunities likely to arise in the surrounding community. These positions range from high-skilled manufacturing roles to administrative and support functions, providing a diverse array of opportunities for local residents.

Beyond job creation, the factory is expected to inject millions of dollars into the local economy through secondary effects such as increased demand for local services and goods. The presence of such a high-tech facility can also attract other businesses and industries to the area, further enhancing economic growth and stability. This economic uplift aligns with broader national goals of revitalizing manufacturing sectors and increasing domestic production capabilities within the United States.

The strategic importance of the new subsea cable factory extends beyond immediate economic impacts, positioning the U.S. as a key player in the global renewable energy market. By localizing the production of essential components like high-voltage submarine cables, the U.S. reduces its dependence on foreign manufacturers and enhances its supply chain resilience, a crucial factor given the increasing frequency of global supply chain disruptions.

The factory directly supports the U.S. government’s initiatives aimed at expanding renewable energy capacity, particularly in offshore wind energy. The cables produced at the facility will be critical in connecting offshore wind farms to the power grid, facilitating the efficient transmission of clean energy across vast distances. This capability is vital for meeting renewable energy targets and achieving long-term sustainability goals.

Navigating Challenges and Seizing Opportunities

As the subsea cable factory moves forward, several challenges loom that could impact its success. One of the primary concerns is the complexity of the subsea cable manufacturing process itself, which requires precision engineering and stringent quality controls to ensure product reliability under harsh marine conditions. Additionally, fluctuating raw material costs and logistical complexities could affect production timelines and costs.

However, these challenges are counterbalanced by significant opportunities. The global demand for renewable energy is on the rise, and with it, the need for robust infrastructure to support such energy sources. The factory is well-positioned to capitalize on this trend by offering cutting-edge solutions that could set industry standards globally. Moreover, as the U.S. continues to invest in renewable energy, the factory could benefit from further governmental support and incentives.

The strategic location of the facility in the U.S. enhances its ability to serve both domestic and international markets, positioning it as a pivotal hub in the global renewable energy supply chain. This strategic foresight could lead to sustained growth and influence in the industry, ensuring that the investment continues to yield returns well into the future.

Sources: