Air Bearings Ltd

Smooth running

With close of 25 years of industry experience, Air Bearings Ltd represents the UK’s leading designer of air bearings, catering to clients of all sizes across a host of applications

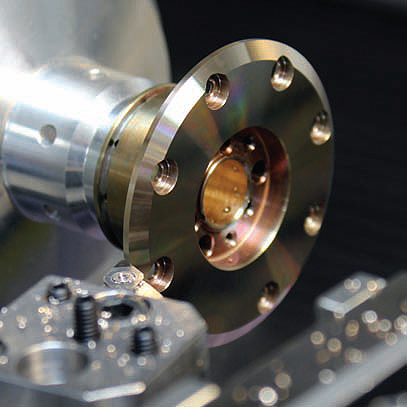

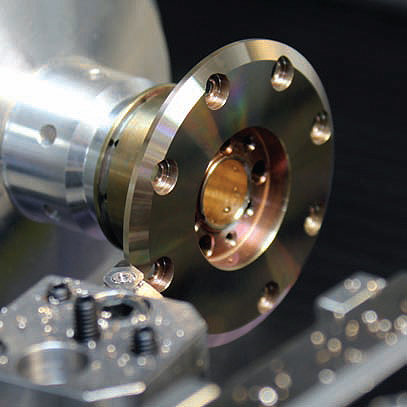

Since the company was established as a joint venture between three partners, Air Bearings Ltd (ABL) has continued to evolve as an innovative manufacturer of air bearing solutions that are used to solve real world engineering problems. Operating as a Via Mechanics Ltd company, ABL boasts facilities in both China and Japan, in addition to its UK base. These holdings are in  turn further supported by a global network of sales offices and agents. “ABL is responsible for every aspect of production, from analysis and design through to manufacture and assembly. Our extensive use of the latest software analysis tools and CNC machining centres ensures that customer’s requirements are met at every stage of the manufacturing process,” elaborates Supply Chain Director, Gary Durrant. “We specialise in the design and manufacture of air bearing spindles for use in precision manufacturing equipment within the printed circuit board (PCB), micro machining, dicing and other high-specification industries. Typical applications for our spindles are in drilling, routing, grinding, cutting and polishing of various materials such as glass, sapphire, graphite, silicon and carbon, used in the production of electronic, optical and composite components.”

turn further supported by a global network of sales offices and agents. “ABL is responsible for every aspect of production, from analysis and design through to manufacture and assembly. Our extensive use of the latest software analysis tools and CNC machining centres ensures that customer’s requirements are met at every stage of the manufacturing process,” elaborates Supply Chain Director, Gary Durrant. “We specialise in the design and manufacture of air bearing spindles for use in precision manufacturing equipment within the printed circuit board (PCB), micro machining, dicing and other high-specification industries. Typical applications for our spindles are in drilling, routing, grinding, cutting and polishing of various materials such as glass, sapphire, graphite, silicon and carbon, used in the production of electronic, optical and composite components.”

Throughout its history ABL has produced in excess of 100,000 air bearing spindles and leveraged proven specialist manufacturing expertise and an extensive global network to build a strong portfolio of clients across several industry sectors. Its main customers are machine and equipment builders located in China, Japan, Taiwan and South Korea, with the majority of its products subsequently exported to these regions. To ensure that it remains at the cutting-edge of manufacturing technology, ABL also employs the latest production equipment and strict quality assurance practices in all of its operations. “The main features of our technology are comprised of the very low rotational friction of air bearings, consistent stiffness and the inbuilt tendency for precise rotational accuracy. This leads to high energy transfer efficiencies, smooth machined surfaces and extreme accuracy,” Gary says. “The main alternative to air bearing spindles are ball bearing spindles. Air bearings provide low maintenance, zero static and dynamic friction, high stiffness and high repeated accuracy and can be successfully used in high precision machining, while ball bearings tend to be used for heavy industrial machining and are often less accurate, require more regular maintenance at higher costs and increased downtime.”

ABL currently has a manufacturing capability for over 200 spindles plus spare parts per month and its main technical ability is in the extremely accurate manufacture of components to around ten per cent of a micron precision. This has enabled ABL to produce solutions such as its LGS10A 12,000 rpm high precision spindle to be employed in environments that demand high accuracy in machining. Close attention to component size and geometric form are required in order to achieve this and the application of new machining methods has enabled ABL to produce spindles capable of satisfying this demanding market. LGS10A was specifically designed to meet the demands of the optical machining industry and offers exceptional rotational accuracy, which is equally suited to any high precision, machining and finishing operations.

Within the field of micro-machining and PCB drilling ABL offers an extensive range of spindles that are suitable for operations at speeds of up to 370,000 rpm. Characteristically these spindles have high stiffness and load capacity, employ liquid cooling and offer low dynamic run out. These spindles are industry proven and afford clients exceptional reliability at an affordable price. These advantages are matched by further application-specific capabilities across additional operations including dicing, drilling and routing, heavy-duty machining and bespoke solutions, meaning that ABL is able to meet the requirements of a diverse base of industrial markets. “Unlike many of our competitors, we design, manufacture and build our spindles and all corresponding spare parts in our UK facility, ensuring we are able to maintain a very high level of quality control and provide a complete service. We are involved with many customers from concept through to production and understand what manufacturing to extreme tolerances means,” Gary explains. “During 2016 we made a significant investment into the company and underwent a full remodelling of our facilities in order to achieve a seamless flow of work through the factory. This work has improved our efficiency so that we are now able to offer even better prices and lead time to our customers.”

spindles and all corresponding spare parts in our UK facility, ensuring we are able to maintain a very high level of quality control and provide a complete service. We are involved with many customers from concept through to production and understand what manufacturing to extreme tolerances means,” Gary explains. “During 2016 we made a significant investment into the company and underwent a full remodelling of our facilities in order to achieve a seamless flow of work through the factory. This work has improved our efficiency so that we are now able to offer even better prices and lead time to our customers.”

While some sectors of the manufacturing industry have endured challenging operating conditions in recent months, ABL has remained focused on all of its clients across the market and continued to progress with confidence and efficiency. Throughout the rest of 2017 and beyond, the company will continue to assist its clients in dealing with the on-going changes within the manufacturing sector, while delivering the highest levels of quality and service. “Over the last few years the PCB industry has experienced very uncertain times. An uncertainty in material requirements and rapid progression in the latest technology on the market has seen a subsequent decline in demand and has meant a slow downturn in manufacturing production. This year the industry is showing signs of picking up and confidence is starting to return, our main objective this year will be outsoucing non key critical parts and focusing on the value adding finishing processes,” Gary concludes. “There are always challenges and opportunities and we pride ourselves in being able to support the transfer of many manufacturing technologies in the journey from prototype developement to consistent volume manufacture.”

Air Bearings Ltd

Products: Reliable air bearing solutions