Alicat Scientific

Process in focus

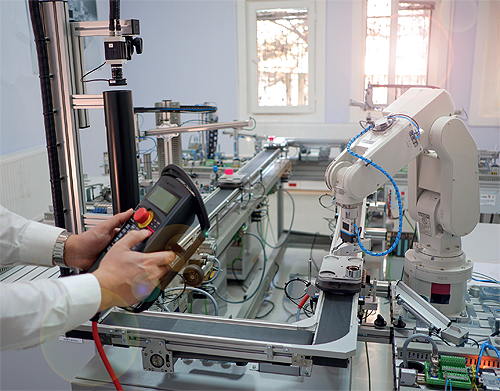

The demands of transitioning to Industry 4.0 are creating the need for new processes to keep pace with tighter tolerances, increased production rates, and adaptive systems aided by machine learning and artificial intelligence. The move from analog to digital systems, using smart sensors to allow for real-time responses to changing system processes, yields increases in productivity and flexibility while allowing plants to adapt to customized and flexible work environments.

One of the key places where these changes occur is the way manufacturers use mixed gas. Historically, the size and complexity of gas mixing systems meant that most industrial consumers of mixed gas bought premixed gas directly from  suppliers. This meant manufacturers had to adapt their processes to consume a limited number of gases with limited flexibility to changing systems on demand. Modern manufacturers increasingly find the need to be able to respond in real-time to changing process conditions.

suppliers. This meant manufacturers had to adapt their processes to consume a limited number of gases with limited flexibility to changing systems on demand. Modern manufacturers increasingly find the need to be able to respond in real-time to changing process conditions.

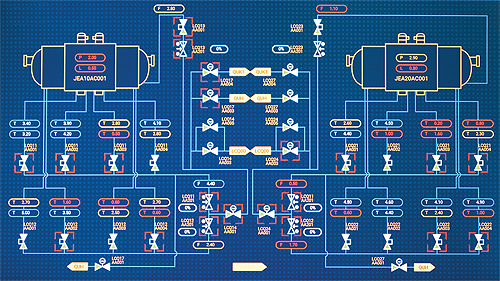

On-demand gas mixing systems answer the needs of today’s smart manufacturing environment. Through the application of smart sensors to the gas mixing process, mixes are traceable in real time and can feed data into process computers. Because of the responsiveness of these systems, changes in process conditions are immediately reported and mixtures adjusted, flow rates changed, or the system shut down in real time.

The ability to rapidly change mixtures on-demand creates flexibility in lean manufacturing situations where production lines pivot between products. Traditional bottled gas requires adaptation to the available gas, whereas a gas mixing system can take inputs of often up to ten different constituent gases and mix them on-demand based on the immediate needs of the process. The result is a manufacturing process that is more agile, more productive, and more cost effective.

Applications like on-demand manufacturing challenge traditional manufacturing and produce an advantage in highly competitive market spaces. The ability for a production floor to quickly change between multiple products allows manufacturers to maintain a competitive edge while diversifying their offerings in unstable market spaces.

Gas mixing systems can programmatically change gas mixtures based on production input allowing for automated changes in production with varying gas mixtures. These mixes can be preprogrammed to flow at set rates, or add a smart sensor down the production line to provide feedback to the gas mixing system. This means that both standard, traceable inputs and IIoT-enabled critical process conditions can be maintained automatically with minimal intervention.

The data is also logged and can be stored locally or exported to centralized databases. Data logging ensures reliable process control and auditing for process improvement or failure mitigation. The results are improved performance, fewer failures, and the ability to constantly refine and improve processes.

A number of industries are already benefiting from the use of on-demand gas mixing systems. Modified Atmosphere Packaging (MAP) used by the food packing industry has seen process improvements through the use of gas mixing systems. The ability to purchase and store cheaper, pure gases which can be mixed as needed has generated both cost savings and flexibility. Digital outputs of these mixing systems also ensure USDA/FDA traceability and give system feedback for real-time quality control.

When it comes to industrial furnace applications, careful control of the gases used and the resultant BTU output are critical. Since many parameters can be monitored in combustion processes (gas flow rates, gas pressures, stoichiometry, temperature, etc.) this data rich environment is ideal for the application of technologically advanced gas mixing equipment. Even as the incoming fuel composition changes, or the downstream heat requirements vary, a properly engineered, modern gas blending solution will adjust autonomously, and in real-time to maintain the desired result.

Many fabrication plants use in-house gas mixers to provide variable, precise multi-gas mixtures to facilitate welding and cutting processes. For heavy industrial applications requiring welding with shielding gases, on-demand mixed gases reduce costs through the purchase and storage of cheaper pure gases. Systems can also be set up to mix different gases for various welding applications. Component gas use is tracked and can be uploaded to data centers for tracking and  inventory maintenance.

inventory maintenance.

For organizations requiring extensive validation and calibration of gas sensors, a single dynamic gas mixing system has the ability to automate a unique blend for each sensor, and rapidly validate sensor functionality. This data is fed into a centralized database and checked against historical data and required tolerances to ensure optimal operating parameters. With tighter control on sensor calibration, affected processes attain more optimal operating environments and generate less waste yielding greater efficiency at reduced costs.

As more manufacturers transition to Industry 4.0 to benefit from IIoT and big data, the move to on-demand gas mixing is an effective way to increase productivity, maintain a competitive advantage, and reduce costs. These gas systems allow for the purchasing of cheaper, pure, gases which can be changed as necessary to adapt to changing processes and conditions while maintaining traceability. On-demand gas mixing systems fulfill the requirement of creating value in today’s real-time, data-driven processes.

Mathew Devitt

Mathew Devitt is Marketing Manager at Alicat Scientific, the leaders in mass flow controllers and flow meter solutions. Alicat pioneered the use of laminar differential pressure flow technology, improving on traditional differential pressure metering. It manufactures and develops custom flow control, flow meter, and pressure solutions for both gas and liquid applications. Its mass flow meters boast the industry’s highest turndown ratio, resulting in fast and accurate measurement over a wide flow range.

www.alicat.com