Orizon’s Unique Journey in Aerospace Innovation

Henry Newell, President, and Charlie Newell, CEO, have been working together since 1996. The earlier days of the brothers’ professional venture together saw them acquiring a number of businesses across different sectors, however they found a life-long passion in the very first sector into which they dove.

“The first company we purchased was in aerospace,” opens Charlie, “and regardless of the other industries we’ve been involved in, aerospace has always been our favorite. Our goal was to build something unique, for us that meant “a vertically integrated aerospace company,” and Orizon has taken many steps to achieve that objective.

“Indeed,” adds Henry. “Historically, between the tier 1.5 to tier two space, there’s never been a large integrated aerospace company that’s been built organically. So, although we did start with two small acquisitions, we have been working to fulfil this vision since 2016, and since then have greenfield over 650,000 square feet and grown our team to over 850 employees. The best part is, everything’s been organic, starting with assembling the most talented team in the industry, developing expertise in machining the most complex monolithic parts in aerospace, processing them in our own chemical plant with proprietary technology, and then putting them together into large complex assemblies.”

“Indeed,” adds Henry. “Historically, between the tier 1.5 to tier two space, there’s never been a large integrated aerospace company that’s been built organically. So, although we did start with two small acquisitions, we have been working to fulfil this vision since 2016, and since then have greenfield over 650,000 square feet and grown our team to over 850 employees. The best part is, everything’s been organic, starting with assembling the most talented team in the industry, developing expertise in machining the most complex monolithic parts in aerospace, processing them in our own chemical plant with proprietary technology, and then putting them together into large complex assemblies.”

In doing so, Orizon is differentiated from the other 19,000 machine shops across the US. As a result of climbing up the bill of materials (BOM) in such a way, and taking on larger assemblies, the organization has a far smaller pool of competitors to contend with. At present, the business has three machine shops in Olathe, Kansas, St. Louis, MO, and Grove, OK. These each feed into its chemical processing plant in Chanute, Kansas, which is accompanied by two assembly-only facilities as well.

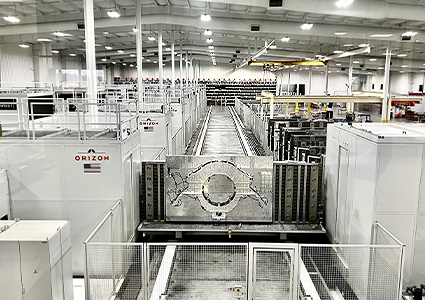

“Our entire site in Chanute has been organically built, a true greenfield project,” Henry states. “We are unaware of another newer or more technology-driven aluminum processing plant than Orizon’s 105,000-square-foot facility in Chanute. It’s responsible for anodizing, penetrant inspection, painting and inspecting all parts, before they’re sent next door to our 200,000-square-foot dedicated assembly facility. With tanks that are 30 feet long, 12 feet deep and three feet wide, this is where we process the most complex monolithic aluminum machine parts. They are ones that the industry relies on, which require a range of chemical treatments. We have prepared a bed/pit for future hard metals processing and are just one contract away from installation.”

The organization’s machine shops host some of the most impressive technology and machining capabilities across the US. At its Olathe facility, Orizon has the largest installation of Modig Rigimill machines in the world, with which it manufactures parts for the thrust reverser and jet engine nacelle of Boeing’s 737 MAX aircraft. Furthermore, the business has turned to absolute automation, meaning that machinists are no longer required to manually hand form or shim any parts.

“One of the acquisitions we made at the beginning was a company in Oklahoma,” Charlie continues, “which had one Starrag EcoSpeed 2060 machine. We were immediately very keen on its capabilities, so we approached the manufacturer and essentially asked them to make us the world’s leading authority on how to operate and maintain their equipment. They were happy to hear it, and even happier that we were willing to send our people over to Europe to learn from them, which is exactly what we did. We also explained to them that once we fully understood their machine’s capabilities, we would buy more from them than anyone has ever done before. Today, with ten machines, wash station and rail guided vehicle we have the largest Starrag ‘2060’ machine installation in the world,” Charlie shares.

“What’s really unique about our system,” Henry interjects, “is that most installations of this nature are dedicated to just a handful of parts. We can serve at least ten different customers, and in doing so, machine almost 200 unique part numbers in the cells, because each of our machines is tooled identically to the other. So, any part can go to any machine. We are staffed to run it 24 hours a day, seven days a week, 350 days a year. Furthermore, it mitigates any risk of downtime as if one machine fails, there are still nine others available. We’ve not seen anything like this elsewhere in North America,” highlights Henry.

“I guess the point of all of this,” Charlie says, “is that we’ve made huge investments with some of the greatest machine manufacturers in the world, and then become the world’s foremost authority on how to operate and maintain their equipment. We’ve tried to differentiate ourselves from our competitors, by employing automation to implement new technological advancements within our facilities. It’s not just how we hold materials, but the ways in which we probe, cut and inspect the parts we make with this great equipment.”

Although Orizon was only established seven years ago, the Newell brothers have spent 27 years forming the foundations for how the organization operates. Continued success is always grounded in hard work and dedication, two key factors that Henry and Charlie have clearly adopted throughout their careers in aerospace. “I’d say that the leading factor that has kept our bond to aerospace so strong for so long, is the people that we get to work with,” Henry states.

Although Orizon was only established seven years ago, the Newell brothers have spent 27 years forming the foundations for how the organization operates. Continued success is always grounded in hard work and dedication, two key factors that Henry and Charlie have clearly adopted throughout their careers in aerospace. “I’d say that the leading factor that has kept our bond to aerospace so strong for so long, is the people that we get to work with,” Henry states.

“Going back to the model that we’ve based our careers on over the last three decades, everything starts with assembling the correct team. I’m proud to say that over the years, we’ve successfully assembled the hardest working and most talented workforce in the industry. They don’t shy away from what can often be the most complex parts and assembly processes around, so we always feel confident in taking big swings against huge projects, because we know that they’re fully capable of delivering winning results every time.”

“I think that’s completely accurate,” Charlie agrees. “We love aerospace because of the unique parts that we get to make, and given that the industry is surprisingly small, you get to know your peers and work alongside them time and again. We’ve partnered with Spirit AeroSystems, Lockheed Martin, Northrop Grumman, Boeing, and are working to find a way to get Airbus onboard, although Orizon is just seven years old, our team has spent almost three decades figuring out who are the best people in the industry. This goes beyond peers and employees to include vendors, suppliers and customers.

“Our plans, as we look forward, generally all revolve around continuing what we’ve done to date, which is to build something unique and move up the BOM. We’re always looking to make something bigger and better than before as a build-to-print contractor. Presently, we’re developing parts for the leading rocket and satellite manufactures, in a new chapter of the space race for reusable rockets and satellites that will provide reliable internet and connectivity to underserved communities around the world. These space components are large, and complex, with incredibly tight tolerances to which we must adhere – exactly the direction that we want to be heading in.”

“We’re working to develop the propulsion element of the satellites,” Henry says. “These have many machine parts attached to them, and we hope, in time, they could eventually lead to us working on much larger assemblies for satellite companies. Another area that’s taking up a lot of our focus is the front end of the process. We’ve developed techniques to machine parts with automation, without any operator intervention, but now we’re working with artificial intelligence too.

“We’ve developed an app called Garfield, which supports our programmers. Essentially, they no longer have to manually program processes, as the app can do so in an automated fashion. Ultimately, it’s a feature-based recognition neural network application that we will be implementing to eliminate all the time it takes to program our machines. We’re using machine-learning and augmented reality software to further automate our machining, inspection and assembly processes,” Henry concludes.

This is by no means your typical mom and pop manufacturing business any longer, Orizon has differentiated itself with its innovative technologies and is truly building something unique!