American-made for over 50 years, custom manufacturer, Montrose Molders, injects passion into every product

With over 50 years of expertise under its belt, Montrose Molders (Montrose) is the industry-leading contract manufacturer that can take on any challenge. Specializing in contract plastic manufacturing, with some metal tooling capabilities, Montrose remains a key pillar in US manufacturing, nationally recognized for its top-tier customer service and constant drive for excellence.

Presently, the business is operated by the third generation of the Wilson family, with Brendan Wilson leading at the helm as President. With Montrose’s 60th anniversary on the horizon, Manufacturing Today sat down with Brendan to reflect on the company’s journey thus far and uncover the secrets behind its longevity and success. He starts by discussing the history of Montrose and how its strong, family values built the foundations of its future success.

“In 1966, my grandfather, Bill Wilson, founded Continental Precision as a tool and die company,” Brendan begins. “Six years later, he started Montrose Molders to run the molds that Continental produced. The companies merged years ago, and the operation grew significantly over the decades to become what it is today. Eventually, Bill passed the torch to his son, Bill Jr, who passed it on to my brother Andrew and I. Throughout the three generations, our family has built a reputation for quality, innovation, and customer satisfaction, and I’m immensely proud of this fact. We started as a small team in a tool shop and today operate two large facilities, delivering critical plastic components to major players in various industries across North America.

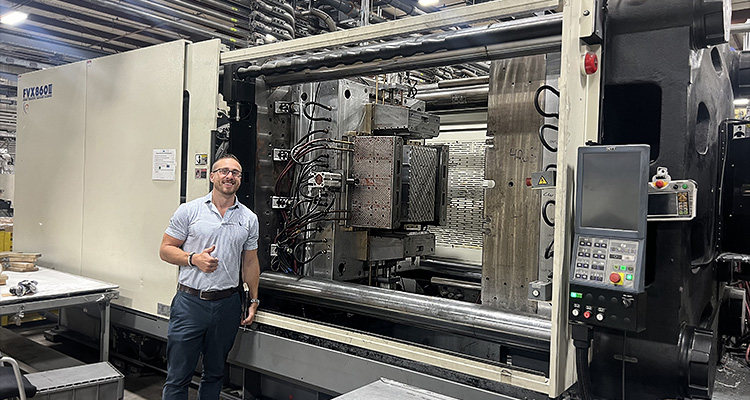

“Today, we have 50 injection molding machines ranging from 40 to 1000 tons of clamp force. In addition to custom injection molded components, we also offer tool and die making, extrusion, assembly, and industrial design. Our products cater to various industries such as lighting, medical, defense, consumer goods, industrial goods, and many more. If it’s a plastic component, no matter how complex, we can make it and make it well. We pride ourselves on our ability to provide tailored solutions that meet the specific needs of our customers.”

Armed with state-of-the-art molding machinery, a tool and die shop, an extrusion department, and assembly facility, Montrose is equipped to provide the very best, delivering high quality, fast lead times and comprehensive custom solutions. The company’s commitment to its customers is the driving force of its innovation strategy, and the business is constantly investing in new technologies to further enhance its R&D operations and production processes.

“Our approach to research and development is centered around continuous improvement. As a custom manufacturer, we are not designing and marketing our own products. Instead, our R&D investments deal with finding better ways to run our customers’ products more efficiently and at a higher level of quality,” Brendan explains. “This includes automation cells, the latest injection molding technology and constant process improvements. Sometimes these improvements are made internally and other times, they are carried out shoulder to shoulder with our customers.

“This year, for example, we invested in five new injection molding machines, two new conventional robots and three six-axis robots. These optimizations will lead to improved process control, greater throughput, and higher quality. The six-axis robots especially will allow us to automate post-molding operations such as hinge flexing, gate trimming, and minor assembly. We have also incorporated Industry 4.0 technologies to monitor the efficiencies of our machines. This allows us to see in real time which machines are running efficiently, and which need to be adjusted.”

“This year, for example, we invested in five new injection molding machines, two new conventional robots and three six-axis robots. These optimizations will lead to improved process control, greater throughput, and higher quality. The six-axis robots especially will allow us to automate post-molding operations such as hinge flexing, gate trimming, and minor assembly. We have also incorporated Industry 4.0 technologies to monitor the efficiencies of our machines. This allows us to see in real time which machines are running efficiently, and which need to be adjusted.”

One of Montrose’s biggest strengths, particularly in terms of quality control and the wider economic climate, is its proud position as a US-based manufacturer. “US-based manufacturing is crucial for us because it allows us to maintain a high level of quality control, ensure faster turnaround times and support the local economy,” Brendan says. “By manufacturing domestically, we can closely monitor every step of the production process, respond quickly to customer needs and reduce lead times. Additionally, it helps us contribute to the growth and sustainability of the local manufacturing sector. We are proud to be a US-based manufacturer, sourcing our components and raw materials from other US-based manufacturers. Not only does this approach make good business sense, but it is the right thing to do.”

2025 has been another successful year for Montrose thus far, and the company is excited to build upon its past legacies as it moves forward into the future. Looking to the years ahead, particularly with the business set to celebrate its 60th anniversary in 2026, we asked Brendan about the factors he feels to be integral to Montrose’s longevity.

“We’re a family business, so we treat our team members like family. This, I strongly believe, is the core reason for our longevity,” he reveals. “Beyond this, we have remarkable customers, many of whom we’ve been working with for decades and decades. Finally, we have a management team willing to invest in the future. To remain competitive, it is critical to be equipped with the latest technology.

“In the years ahead, we will expand into challenging new market segments. We will invest heavily in training and developing the next generation of talent and in the latest robotics in automation to stay efficient and competitive. We will continue our pursuit of excellence.”

As our interview draws to a close, it’s clear that Montrose will remain a market leader for many years to come as it continues to mold a better future for the manufacturing industry. Concluding our conversation, Brendan is keen to share a message to those the business holds closest.

“I’d just like to thank our team members, vendors and customers for their continued support and trust in Montrose Molders. As we look to the future, we remain committed to delivering exceptional products and services, and we are excited about the opportunities ahead.”