Amid industry challenges, Novarc Technologies is redefining the future of welding

As global manufacturers face growing pressure from labor shortages and rising production demands, one Canadian firm is transforming an age-old trade with the precision of robotics and the intelligence of AI.

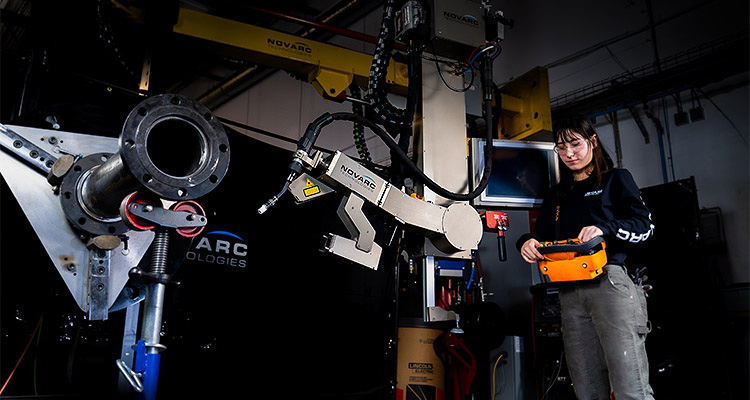

Pioneers in autonomous welding, Novarc Technologies (Novarc) provides cutting-edge cobots, robots, and AI-driven solutions that redefine industrial capabilities. As a globally trusted leader in welding automation across multiple sectors, Novarc’s technologies have been proven to maximize productivity and promote a new era of manufacturing. With significant skilled labor shortages facing several industries including welding, many manufacturers are tasked with finding solutions to automate processes where possible with the aim of driving greater efficiency and extending the existing labor force.

A welding breakthrough

The company was founded in 2013, with Novarc’s first Spool Welding Robot (SWR™) prototype established in 2015, which was the world’s first of its kind in pipe welding applications. Following design tweaks, the first SWR was installed in Ontario, Canada, in 2016, but it was officially launched at FABTECH in Chicago in 2017.

The SWR was the first collaborative robot purpose-built for pipe welding. The technology didn’t just automate welding; it redefined the process. Customers report up to a 12-fold productivity increase in stainless steel welding and three- to five-fold gains in carbon steel, with repair rates below one percent – a metric that exceeds industry norms.

Having since grown its presence to four continents (North America, Europe, Asia, and Australia), Novarc’s technologies are streamlining operations across the globe. Soroush Karimzadeh, CEO and co-founder of Novarc, joins us to elaborate on the company’s journey so far. “Novarc focuses on solving tough welding automation challenges that have not previously been addressed by the industry,” he opens. “Our SWR is an advanced welding cobot designed to increase productivity and improve weld quality in pipe and roll welding applications. Companies using the SWR have achieved significant results, including increasing productivity by up to 12 times in stainless steel pipe welding productivity and three-to-five times in carbon steel.

“Precision is another key advantage, with less than one percent repair rates, which far surpasses industry standards and ensures adherence to rigorous testing requirements. The SWR also has the smallest footprint in the industry, and when combined with our Welding Vision System with insights from NovData, it offers an unparalleled, world-class solution. The robot can be customized to specific customer needs, with options for single torch, dual torch, and SWR-F, as well as positioner and BIM software integrations.”

requirements. The SWR also has the smallest footprint in the industry, and when combined with our Welding Vision System with insights from NovData, it offers an unparalleled, world-class solution. The robot can be customized to specific customer needs, with options for single torch, dual torch, and SWR-F, as well as positioner and BIM software integrations.”

Unlike other welding solutions, Novarc’s flexible technologies can weld a variety of joints with fewer space restrictions, where operators interactively adjust during the weld without the need to pre-program. Building on the SWR, the SWR-TIPTIG is a cobot designed specifically for pipe, pressure vessel, and roll welding applications using the Gas Tungsten Arc Welding (GTAW or TIG) process. This system pushes the limits of TIG welding to new heights, using the advanced TIPTIG system to enhance both speed and precision beyond conventional standards.

Beyond the spool

“We very recently launched a new product, NovAI, a computer vision, AI-powered robotic vision system,” Soroush adds. “NovAI brings vision, cognition, and real-time adaptation to articulated robotic and mechanized welders. The system increases the ROI of automated welding and ensures control over weld quality, allowing companies to automate tasks that couldn’t previously be automated.

“We’ve learned a lot from speaking with customers and identifying their specific needs. Adaptive welding is a longstanding issue in robotic welding, but we can solve this problem by leveraging our experience in spool welding and computer vision systems. There are always part variations in the process, but our SWRs can react to different scenarios as they occur.”

Commenting on skills shortages, Soroush continues: “We know that the entire industry is facing significant welder shortage issues, which can be somewhat eased by welders automating their pipeline processes. Not only do our solutions help operatives, but they also positively impact workplace environments by improving working conditions. By using robots, human welders are still in the loop as the robots need supervision, but workers are not exposed to the long-term hazards associated with carcinogenic gases. Improving these conditions and eliminating risk hugely contributes to attracting a new generation of welders to join the industry.”

On the topic of working environments, Soroush outlines some recent changes to the company’s office space. “We’ve recently consolidated our three offices in Vancouver into one office, so our manufacturing, supply chain, customer operations, R&D, engineering, finance, and administration teams are all under one roof in Burnaby, British Columbia,” he says. “As we eye expansion in both new and existing markets, we’re continuing to build a high performing team of smart, humble, and motivated people.”

Considering the company’s impressive growth, we ask Soroush his thoughts on what factors have fueled such success. “We’ve certainly come a long way from building a prototype of the SWR in 2015,” he reflects. “We’ve grown in several sectors since launching the SWR in 2017 and we’ve scaled our manufacturing, supply chain, and customer operations teams to support this growth. Historically, we’ve worked with the oil and gas industry, ship builders, and mechanical contractors, building pipes and modules for high rise buildings, stadiums, ships, LNG plants, and carbon capture plants. With our SWR and NovAI products applicable to alloys and stainless steel, we’re able to expand into new markets like semiconductors, food and beverages, automotive, or even nuclear and aerospace.”

Novarc not only produces these solutions but also supports customers throughout the journey. “We install all the units ourselves and our customer experience team supports customers throughout the process,” Soroush explains. “We’re proactive with our customers and we regularly reach out to see how they’re getting on with our solutions and the benefits they’re experiencing. By maintaining positive relationships, we build trusted partnerships with our customers, which often leads to repeat business or recommendations.”

As industries across the globe grapple with skills shortages and a pressing need for greater efficiency, Novarc is clearly leading the way with autonomous welding solutions. From pioneering solutions like SWR to AI-powered systems like NovAI, Novarc is not only filling talent gaps, but increasing productivity and enhancing quality.

“Demand for welding is constantly growing, and with welder shortages across the globe, automation is a clear solution to ease pressure,” Soroush concludes. “With the use of AI in the welding industry only expected to increase, new AI solutions are continuously emerging. We strive to develop great products aligned with our growth roadmap, and we’re proud and excited to be at the forefront of the industry’s adoption of AI.”