An unwavering dedication to innovation and continuous improvement ensures TAMKO’s long-lasting legacy

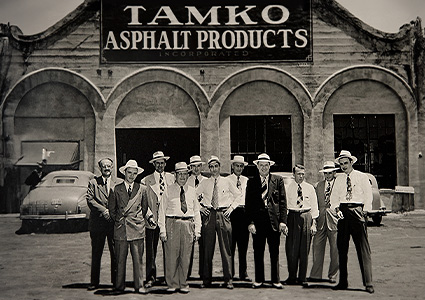

Established in 1944, TAMKO provides roofing solutions to contractors across the US. As the company celebrates a landmark anniversary, Chief Operating Officer, Jeff Beyer, discusses the secret of its success: “TAMKO is a really great story of American entrepreneurship. This year we’re celebrating 80 years in business, which is a huge milestone for us. The company was founded in 1944, by an entrepreneur named E. L. Craig. At the age of 69, he invested his life savings into a roofing business. Since then, TAMKO has remained a privately-owned, family led operation, spanning three generations. The company name is an acronym, which represents the five US states the company expected to serve: Texas, Arkansas, Missouri, Kansas, and Oklahoma. The name TAMKO is still very meaningful to this day, as it represents the company’s initial footprint, and demonstrates how far it has come.

“We’ve continued to grow and evolve over the last 80 years, and today TAMKO is one of the leading manufacturers of residential roofing products with sales in all 48 contiguous states. Our longevity is due to our ability to innovate, adapt to changes and provide high quality roofing products.

“We’ve continued to grow and evolve over the last 80 years, and today TAMKO is one of the leading manufacturers of residential roofing products with sales in all 48 contiguous states. Our longevity is due to our ability to innovate, adapt to changes and provide high quality roofing products.

“We’ve been able to grow and thrive by adopting Deming’s continuous improvement methodologies. Deming’s teachings, along with anti-tampering, automation and Six Sigma methodologies help TAMKO improve efficiency, quality, and service. At TAMKO we use these tools to make data-driven decisions and identify areas for improvement.”

Technology adopters

The company’s product portfolio, like everything else, has grown and evolved over the years. TAMKO now provides a diverse range of leading-edge products for contractors in the residential market, as Jeff discusses: “Our product has changed over the years, but it’s always served the same purpose: to protect the home.

“Our products keep a house watertight and defend the inside from the outside. We have three different lines of shingles, including a more economical three-tab shingle line called Elite, our classic Heritage laminated shingle and our high performance, award-winning Proline shingles: Titan XT and StormFighter Flex. The product range is strategically designed to hit a variety of price points, while ensuring all pieces are fit for purpose. We also aim to be a one-stop shop for roofing materials, which is why we offer the supporting items a customer might need.”

Despite its historical roots, TAMKO has always been a future-thinking business. As Jeff affirms: “We’ve always been early adopters of the latest technology and that’s helped us stay ahead of the curve in many ways. It’s important to understand that technology isn’t just a means to an end; it needs to serve a purpose. We invest in new machinery or automation if it can help improve efficiency, reduce variation, or improve the quality of our products.

“Today’s technology gives us access to more accurate, or up-to-date, data on our operations. For example, we now have sensors on our manufacturing lines giving us hundreds of data points every second. Using data, digital twins and AI/ML, we can gain greater insights into the manufacturing process. With these data we are also learning the optimal setpoints and inputs.”

Cohesive culture

This culture of continuous improvement extends far beyond the product line – it’s also an integral part of daily life at TAMKO. As Jeff states: “As individuals working together, the TAMKO team strives to deliver innovative, high-quality products and we seek to get better every day. At TAMKO, we live our values. We believe in honesty and integrity. We believe in sticking to your word, always following through on promises and treating everyone fairly and with respect. We are intentional about culture creation and the result is a cohesive team that truly believes in the company and our mission, vision and culture. As a result, TAMKO enjoys extremely long tenure among our team members. In addition, over 15 percent of our team members are veterans.”

together, the TAMKO team strives to deliver innovative, high-quality products and we seek to get better every day. At TAMKO, we live our values. We believe in honesty and integrity. We believe in sticking to your word, always following through on promises and treating everyone fairly and with respect. We are intentional about culture creation and the result is a cohesive team that truly believes in the company and our mission, vision and culture. As a result, TAMKO enjoys extremely long tenure among our team members. In addition, over 15 percent of our team members are veterans.”

Ongoing innovation has kept TAMKO thriving for 80 years, and it’s clear that the company’s long history is far from over. There are many more challenges to face, products to build, and markets to serve, as Jeff details: “It’s a really exciting time for us at the moment. On the manufacturing side, we’re using AI, autopilot and digital twin technology to create breakthroughs in manufacturing in terms of increased productivity, reduced waste and improved quality. On the product side, we’re building out the performance product category and working closely with roofers to understand their needs and how we can provide solutions. In addition, TAMKO is also focused on how to manufacture products more sustainably.

“We’re excited to build out our partnership with Northstar Clean Technologies. Northstar’s mission is to be the leader in recovery and reprocessing of asphalt shingles in North America. So, it was a natural fit with TAMKO. TAMKO’s relationship with Northstar will not only help us make more sustainable shingles but also diversify and add resilience to our supply chain. Northstar is in the process of selecting the first location on the east coast and is looking to add several more North American facilities.

“TAMKO currently has five shingle manufacturing plants and six other plants supplying those shingle plants. This vertical integration lowers costs, reduces variation, minimizes supply chain risks and improves quality. Our plan for the future will be to strengthen that network. Looking forward, TAMKO expects to continue to invest in great people, tools and facilities to provide innovative, high-quality products that address the needs of roofing professionals and homeowners,” he concludes.