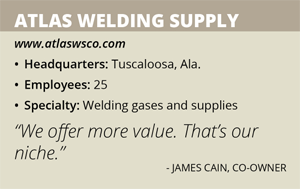

Atlas Welding Supply

Atlas Welding Supply participates in an industry that has consolidated significantly over the past few years, but co-owner James Cain continues to see favorable circumstances for his company. “The consolidation in our industry is both a challenge and an opportunity,” Cain says.

Cain admits that consolidation has led to increased competition from national and regional firms that have distinct advantages, as well as weaknesses. For example, there is a perception the larger companies can outbid Atlas Welding Supply, but they cannot exceed the service offered by the Tuscaloosa, Ala.-based company that has developed a strong reputation among clients.

Atlas Welding Supply maintains that reputation by continually increasing efficiency, reducing waste, improving safety and providing accurate transactions, Cain says. “We offer more value,” he says. “That’s our niche.”

For example, Atlas Welding Supply has cultivated long-term relationships with many of its customers and often suggests ways they can improve safety and efficiency, as well as reduce labor costs. “It’s about services,” Cain says. “We try to be the high-value provider. We seek to reduce our clients’ labor costs by up to 10 percent by improving efficiency or reducing cycle time. Sometimes larger companies may not take the time to show a customer a solution.”

For example, Atlas Welding Supply has advised clients to update gas delivery systems, thereby eliminating the time lost when workers must stop to change tanks, Cain says. The company positions itself as a consultant for its customers. “Our decades of experience mean we also increase workplace safety, lowering your exposure, while reducing or eliminating lost time work cases,” Cain adds.

Atlas Welding Supply also connects with its customers via delivery services that go beyond dropping off tanks and other supplies. “Our delivery folks know the customers and have become part of the workforce at their facilities,” Cain says. “We advise them what they need and why they need it. We sell solutions instead of selling products. That’s our competitive advantage. The value we deliver becomes a tangible and sustainable benefit for our customers.”

Atlas Welding Supply also connects with its customers via delivery services that go beyond dropping off tanks and other supplies. “Our delivery folks know the customers and have become part of the workforce at their facilities,” Cain says. “We advise them what they need and why they need it. We sell solutions instead of selling products. That’s our competitive advantage. The value we deliver becomes a tangible and sustainable benefit for our customers.”

Significant Results

The company’s market approach and expertise certainly have paid off. Atlas Welding Supply has quadrupled in size since Cain and partner Bill Visintainer bought the company in 2008.

The owners have added locations in Fayette and Greensboro, Ala., and acquired a Birmingham gas distributor. The expansion allowed Atlas Welding Supply to increase its service area to include parts of Tennessee, Georgia and Mississippi. However, more the 90 percent of the company’s clients are located in Alabama. “We’ll go where the opportunities are,” says Cain, who worked in the financial services industry before purchasing the company.

Adjusting the company’s offerings is another reason for its success. Atlas Welding Supply primarily sold equipment when Cain and Visintainer took over. The duo worked to adjust the product offerings so that gases and gas services including the onsite filling of helium, propane, propylene, oxygen, nitrogen and CO2 were a more significant part of the business. The company also joined the Gas and Welding Distributors Association, which exposed it to more networking and partnership opportunities with customers and other providers in the market.

Atlas Welding Supply sells supplies including industrial gases, specialty gases, gas and cutting equipment, safety products, tools and hardware, and welding products to a variety of industries. “We sell compressed gases to the steel fabrication industry,” Cain says. In fact, steel fabricators comprise about 50 percent of the company’s clientele, he says.

The medical industry, especially dentists who require nitrous oxide and medical oxygen, has become a significant contribution to revenues. Atlas Welding Supply also works with metal manufacturers, steel erectors, and the beverage and food industry. “We sell propane for heating, cooking, and motor fuel,” Cain says.