August Electronics: Leading EMS Through Growth & Innovation

August Electronics (August) is a world leading provider of electronic manufacturing services (EMS) in both traditional and emerging industries. With over 30 years of industry experience and an 85,000-square-foot manufacturing facility, the business is well-equipped to support clients through the entire product development lifecycle.

Having recently transformed the business, we sat down with some of August’s management team – Tanya Korenda, COO and Co-Owner, Paul Crawford, CEO, and Jason Johnstone, Vice President of Sales – to discuss the company’s continuous development and recent investments.

“August was established in 1991 by its two original co-owners, Jack Francis and Peter Wilson,” begins Tanya. “They’d done design work for several years, and then came to the realization that they could not only provide design services but could also offer high-quality, reliable manufacturing of products that meet the needs of a wide range of industries and applications. Customers positively agreed and August transformed into a contract manufacturer (CM).

“I joined in 2007 to help the existing company win over a large client with my extensive experience in the electronics manufacturing field,” she recalls. “I worked in railway electronics before August, so I was brought on to ensure the efficiency of our processes and generally continue the company’s growth strategy.”

“I joined in 2007 to help the existing company win over a large client with my extensive experience in the electronics manufacturing field,” she recalls. “I worked in railway electronics before August, so I was brought on to ensure the efficiency of our processes and generally continue the company’s growth strategy.”

By the time Tanya joined the business, August was concentrated on growing its manufacturing operations. “Simply put, we take a finished, pre-designed concept and manufacture it,” Tanya states. “We help our partners navigate the New Product Introduction (NPI) and Design for Manufacturing (DFM) processes, tweaking elements of the design to save cost or facilitate mass production, for example.

“While we no longer offer concept design services, we have enhanced our DFM and CM capabilities,” she adds. August can now support customers at any stage of the product’s lifestyle, whether it’s providing feedback on board designs or enabling traceability and transparency through the manufacturing process by developing custom internal software.

Rather than targeting specific industries, August’s team of expert engineers and operators are experienced and knowledgeable across several diverse markets. The team prides itself on delivering high quality contract manufacturing while still meeting delivery deadlines and exceeding client expectations, regardless of the industry.

Paul elaborates: “We are more concerned with finding the right customer for us, rather than focusing on particular industries. So, when we look at working with a new partner, we analyze whether they will be a good fit for us and interview them as much as they’re interviewing us; we like to enter contracts having alignment with culture and values, as well as being confident in our ability to deliver the customers’ expectations.”

Turning to his personal involvement with August, Paul continues: “What intrigued me about August when I joined two years ago as CEO was its vision for growing the business. I think businesses, just like people, should continually strive for growth. Growing a company not only provides opportunities to expand, but also allows individuals to develop their skills in new roles and challenges.

“One of the first things I did when I became CEO was survey a range of our current customers to find out what is working well, what they liked about August, and where there could be room for improvements,” he recalls. “A common recommended area of improvement was our sales team and their communication with customers, so Tanya and I sat down to discuss how we could implement the changes we knew were needed.”

where there could be room for improvements,” he recalls. “A common recommended area of improvement was our sales team and their communication with customers, so Tanya and I sat down to discuss how we could implement the changes we knew were needed.”

Jason details: “Within a short span of 18 months since joining the company, we have undertaken a significant overhaul of the sales team, with a customer-centric approach in mind. We have doubled the number of account managers, for example, and are implementing a new software program to facilitate seamless communication with our customers, especially concerning supply chain constraints.”

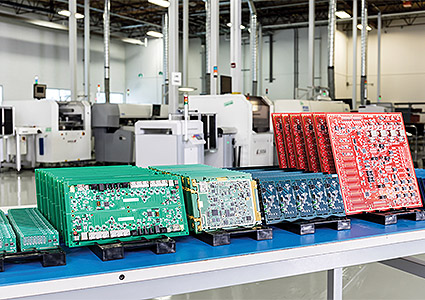

August continues to invest in its people, equipment, and technology. “We’re currently investing in capital equipment with the aim of expanding our production capacity in areas of the business that are increasingly growing in demand,” Tanya reveals. “We are purchasing new Surface-Mount Technology (SMT) equipment, for example, and we are seeing growth in conformal coding. We’re also assessing ways to change the layout of our facility to maximize production, as well as bringing in some innovative mechanical assembly and testing equipment.”

Aside from developments in its core business, August is committed to investing in the community. “We support educational and sports organizations, like high-level athletic teams and robotics clubs,” says Tanya. “Perhaps our biggest commitment in the community is supporting the community programs in Calgary, that do amazing work with young parents and expectant teenage mothers. There has never been a more pressing time to support younger generations, so we are always looking for new ways to empower these individuals.”

This dedication to supporting the local area extends to August’s own community. “At the end of the day, our employees spend many of their waking hours at work, and we want to make sure they’re smiling both at work and at home,” Tanya reflects. “It’s been really rewarding to encourage a healthy work/life balance across the team and be part of people’s growth over the last two years.”

Tanya’s passion for enriching people’s lives is evident in her plans for the future of the company. She proposes: “We will continue to encourage our team to spend time together as a team outside of the workplace to ensure they grow not only professionally, but also socially.

“On the professional side, we have a strategic growth plan of 20 percent year-over-year for the next five years,” she concludes. “So, I’d love to see us hit those targets as well as continue to grow our positive company culture.”