Avgol

Resins to believe

When Avgol began its operations in 1988, its primary focus was the manufacture of fabrics for baby diapers, along with baby bags, feminine hygiene pads, adult incontinence pads, and other products for the hygiene sector. “Until 2019, that constituted 95 percent of our business,” reveals Tommi Bjorman, CEO at Avgol. “Then along came Covid-19.”

When first identified in late 2019, few could have predicted the full extent of the impact of Covid-19. Although much of life ground to a halt in the ensuing months, Avgol found itself busier than ever – identified as a critical manufacturer, the company quickly pivoted towards the supply of personal protective equipment (PPE).

“The Covid-19 pandemic was, and continues to be, an event during which Avgol has played a globally pivotal role in doctor, nurse, and patient PPE supply,” Tommi states. “Key component materials required for personal protection and hospital care are now produced on our lines. Although prior to the pandemic we had focused much of our commercial efforts on being a leader in hygiene products, the urgent need to effectively fight against the virus allowed Avgol to rapidly step up and flex its technical capabilities to manufacture products for the medical and PPE markets.

“While the pandemic posed a significant challenge to our capabilities and capacities, it wasn’t as if we could simply turn away from the continuing demand,” he goes on. “In many countries, the need for hygiene products was heightened as many consumers began to stockpile. Avgol met each of these incremental requests for component materials while ensuring no existing or new customers were met with shutdowns or loss of supply.”

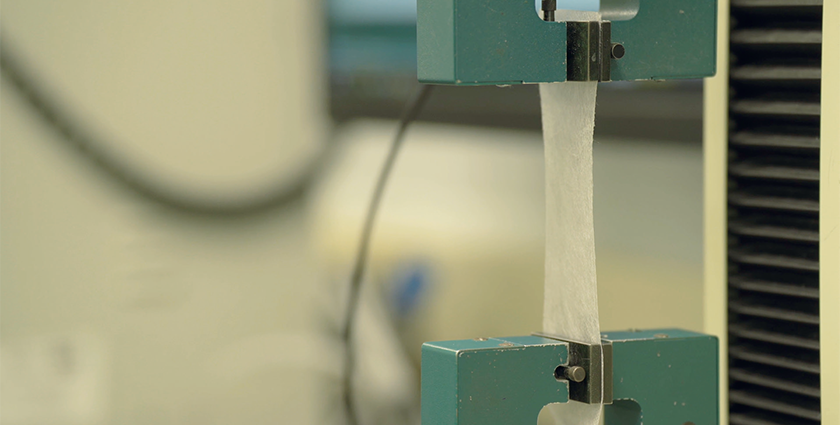

Today, Avgol is the global market leader in the manufacture of high-performance spunmelt nonwoven materials, catering to a wide range of sectors, including hygiene, medical, and functional materials. “Our manufacturing lines typically begin with polypropylene pellets , in volumes ranging from 30-kilogram bags, all the way up to whole train cars full of resin,” Tommi explains. “We take that resin, melt it, extrude it in different ways, and convert it directly into fabric.”

Avgol entered a new chapter in 2018, when the business was acquired by Indorama Ventures Limited (IVL), a world-class chemicals company with a global integrated leader in PET and fibers. But despite the change in ownership, Avgol continues to develop industry-leading products – for which Tommi is keen to stress the continued importance of taking a consumer perspective.

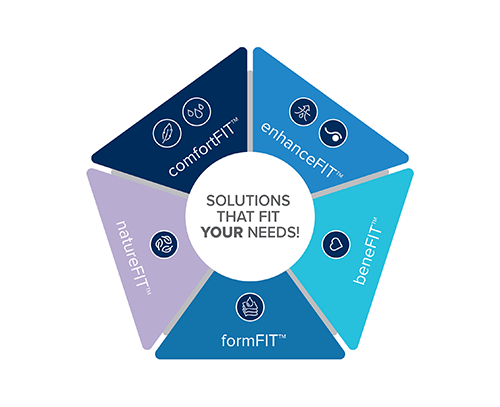

“There is the adage that ‘an ounce of prevention is worth a pound of cure’,” he says. “At Avgol, we could not agree more. That’s why we developed and now follow our Forward Innovative Thinking (FIT) component strategy, allowing product designers the ability to intermix functions and capabilities to generate consumer products that improve the quality of life.”

At the heart of Avgol’s FIT strategy are currently five families of capabilities that specifically target ways to eliminate issues that negatively impact the consumer experience. These are: beneFIT, focused on system components that reduce the potential negative effects of microbes, improve skin integrity and problems such as rashes; comfortFIT, focused on methods to improve user experience including softness and liquid management; enhanceFIT, covering functionalities that address breathable barrier and absorbency enhancement; formFIT, which includes ways and means to change the fundamental fabric construction and composition; and natureFIT, which centers around achieving the above with bio-sourced alternatives, and a reduced environmental impact.

“When the FIT strategy is applied as a combination of capabilities, component materials are produced that help reduce many of the negative issues that consumers can experience when using hygiene products, including those that require personal expenditure to resolve,” Tommi tells us. “Such expenditure includes purchasing salves and ointments, or potentially the worsening of such issues over time and the need for medical attention, and the related complexities of having the time and means for acquiring such remedies. We collaborate closely with our customers to ensure problems such as rashes can be prevented when hygiene products are thoughtfully created, versus having to cure problems that might result.”

The majority of Avgol’s traditional consumer research has centered around comfort, enhancement, and form. But recently, product sustainability has become an increasingly important factor that is driving consumer habits. “Both the diaper and PPE industries generate a lot of waste,” Tommi points out. “What do you do with all that waste? That’s where we are more involved with new technologies, exploring the environmental impacts of what we produce, and how we produce it.”

For Tommi, it’s possible to breakdown this process into three distinct phases. “The first is the beginning-of-life, where you’re looking for such things as plant-based resins instead of crude oil-based resins,” he outlines. “Then you get into the in-use phase. In the example of the top sheet for a baby diaper, those fabrics might once have been 20–25 grams-per-square-meter in weight. Nowadays, you can find products that are 11–12 grams-per-square-meter, that achieve the exact same, or even better results. This is quite important when it comes to reducing how much resin is used to make these components.”

The final phase is end-of-life. “This is where you get into such things as recyclability, which can be a little complicated when you think about a diaper, because they’re comprised of so many different parts,” Tommi explains. “For us, this is where we look at such things as making a larger number of components out of the same kind of resin, so that it’s more homogeneous. We can also look at biotransformation technology.”

Biotransformation is a unique functionality, created in close collaboration with Polymateria Limited, wherein a conventional nonwoven fabric can be modified to react to certain triggers, including the combined effects of air, moisture, and sunlight, to initiate a fundamental chemical change of the polymer resin into a wax. This resulting wax is readily consumed by natural bacteria normally found in the environment. Once triggered, the material will continue to the point of forming low molecular weight wax compounds, with no microplastics left behind to cause other environmental problems.

Biotransformation is a unique functionality, created in close collaboration with Polymateria Limited, wherein a conventional nonwoven fabric can be modified to react to certain triggers, including the combined effects of air, moisture, and sunlight, to initiate a fundamental chemical change of the polymer resin into a wax. This resulting wax is readily consumed by natural bacteria normally found in the environment. Once triggered, the material will continue to the point of forming low molecular weight wax compounds, with no microplastics left behind to cause other environmental problems.

“End of life issues with products that are comprised of nonwoven fabrics are as complicated as they are numerous,” Tommi concedes. “Used-product wastes, whether the simplest wipe material, the most prolific face masks, or the most complicated baby diapers, all utilize polymeric resins that suffer from a two-edged sword – a high degree of inertness and stability, while also being difficult to recycle and degrade.

“By bringing biotransformation technology to the disposable wipe, PPE, and hygiene markets, we hope to offer a real-world solution to this issue,” he continues. “In particular, we want to address aspects of the creation of fugitive waste, and the removal of such waste from the environment without causing additional, and potentially more dangerous problems.”

To facilitate these ambitions, Avgol has made some significant investments in its manufacturing footprint across recent years. Among its purchases is a host of new Reicofil equipment from renowned German-based brand Reifenhäuser. “They’re the company with the most patents, and the biggest support infrastructure for equipment for the production of spunlaid fabric,” Tommi indicates. “We currently have Reicofil 3s and Reicofil 4s, but a fifth generation has been introduced, which we target bringing to our future expansions.”

Avgol currently boasts six manufacturing locations throughout Israel, the US, Russia, China, and India. In July, Avgol celebrated the latest addition to this footprint, with a new manufacturing site at Halol, located in the Indian state of Gujurat. It’s a move that’s set to deliver an expanded capacity Reicofil line, while also bringing greater domestic capability to support advanced spunlaid products, including spunbonded meltblown laminates. As Tommi explains, it’s an investment designed to meet Avgol’s increasing demand from the Indian market.

“There’s a growing penetration rate, in which more and more people within that market are looking to use products that include spunlaid nonwoven fabrics as part of their construction,” he says. “With the development of the Indian middle class, families are now finding that they have the discretionary income to purchase items like diapers and incontinence products. India is also a rapidly growing organic market, and one very interested in internalizing its production capabilities, relying less heavily on imports.”

Turning to the future, Avgol hopes to maintain its focus on product design, with plans to introduce yet more sustainable polymer technologies. But for Tommi, the challenge of sustainability can’t be solved by any one company alone. Instead, he argues, the industry will need to work together in order to stay relevant.

“When you look at the nonwoven industry, the vast majority of our products have very short, or single use-lives,” Tommi argues. “With that in mind, we have to be conscious about how we’re using resources, whether it’s the resins we utilize, or how we obtain the energy to run our lines, to being considerate with regards to our logistics. We’ve got to be smarter about how we obtain plastics, how we use plastics, and how we recycle plastics back into alternate or similar applications. We’re pushing our industry organizations to take a lead in making sure we’re working in harmony across all aspects of the supply chain. By doing that, we can make the kinds of improvements that people want to see.”

Avgol

Services: Spunmelt nonwoven fabrics manufacturing