AXH air-coolers is embracing growing markets and opening new facilities

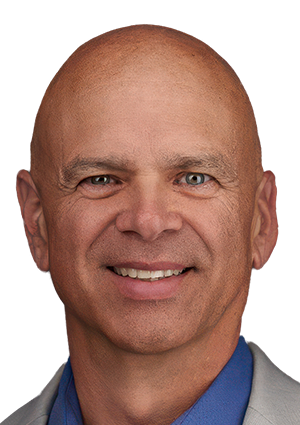

AXH air-coolers (AXH) celebrated its 20th anniversary by announcing the ground breaking of a new 26-acre campus in Sapulpa, Oklahoma. Chief Operating Officer, Jim Simmons, elaborates on the company’s history: “Our founding partners were sales and applications engineers for another manufacturer for several decades before deciding to commence building their own product which led to the 2005 purchase of the initial 129,000 square-foot facility on ten acres in Claremore, Oklahoma. Today, the AXH Claremore Complex consists of 750,000 square feet of manufacturing facilities on 93 acres with almost 800 employees. With the addition of the Sapulpa Campus, when both Phase 1 and Phase 2 are completed, AXH operations in NE Oklahoma will cover over 115 acres with over 1000 employees.” Jim reflects that “when we first moved into the Claremore facility, we thought we’d never fill up the original 129,000-square-foot building. Within the first six months though, we were already making expansion plans. Since then, we have just continued to grow.”

While AXH started by primarily manufacturing air-cooled heat exchangers for the natural gas compression industry, today it serves a broad customer base across the upstream, midstream, and downstream markets. Most recently, AXH has gained a very favorable reputation within the LNG, carbon capture and other renewable energy markets. AXH has also recently begun supporting the rapidly growing data center market and believes the future is very bright for its products. Jim comments that “any time a fluid or gas needs to be cooled during compression or other process application an air-cooled heat exchanger will likely be required.” He shares that air-coolers are increasingly favorable when there isn’t an abundance of water so as water scarcity becomes more prevalent in many regions, air-coolers are going to be increasingly considered as a great solution.

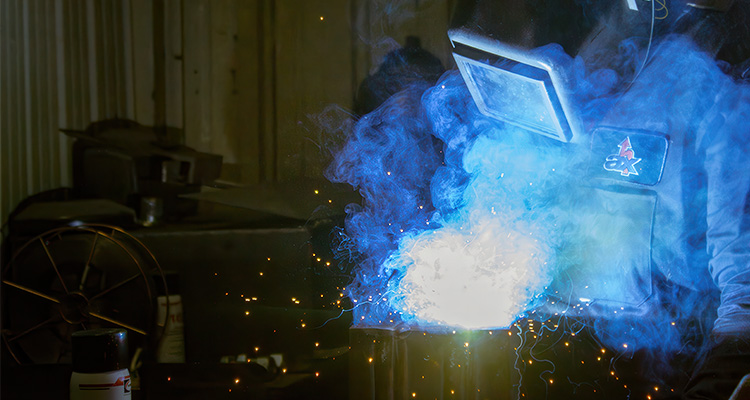

Relative to its operations, one of the things that makes AXH unique across its industry is that it does very little out-sourcing of its key components or processes. Jim explains: “It is our belief that starting with raw plate and steel allows us to offer the shortest lead times and highest quality in the industry while controlling costs.” He further elaborates that “another thing that makes us unique, besides the sheer scale of our operations and the quantity of air-cooled heat exchangers produced, is the fact that we produce almost every industry standard model on a weekly basis. We believe this manufacturing flexibility allows us to support a broader customer base in a unique way.” One of the results of this product flexibility is that visitors to the AXH campus will see products that range from “the size of a suitcase up to those as large as a small house, and just about everything in between.”

When discussing the company’s operations and attitude toward them, Jim outlines the approach to automation: “We utilize technology and automation wherever possible. Whenever we can improve our manufacturing processes, we take that opportunity. We believe in the theory of constraints, so we identify what our biggest constraint is across the operation or in a given area and then work out how we can overcome that challenge before moving on to the next one. For example, right now we are in the process of upgrading our sheet and plate processing capabilities.

“Historically, AXH has utilized high-definition plasma as its primary method of processing sheet metal and plate. However, as laser technology has advanced and become more economical, we are now moving rapidly to incorporate this faster, more efficient, and cleaner process. AXH just recently took delivery of its first laser and has two more on the way. We’re always open to alternative solutions that help us improve and become more efficient. Another great example is our automated beam line for processing structural steel, which integrates with our drafting system. Anything that makes life easier for our manufacturing team, produces superior quality, and reduces cycle times is a win and ultimately this translates to benefits to our customer.”

“Historically, AXH has utilized high-definition plasma as its primary method of processing sheet metal and plate. However, as laser technology has advanced and become more economical, we are now moving rapidly to incorporate this faster, more efficient, and cleaner process. AXH just recently took delivery of its first laser and has two more on the way. We’re always open to alternative solutions that help us improve and become more efficient. Another great example is our automated beam line for processing structural steel, which integrates with our drafting system. Anything that makes life easier for our manufacturing team, produces superior quality, and reduces cycle times is a win and ultimately this translates to benefits to our customer.”

Besides the products it has been manufacturing for 20 years, last year, AXH stood up a formal Aftermarket and Field Service Division, and then in July 2024 acquired KT MAC out of Bryant, Arkansas to immediately expand its field service reach and capability. “The KT MAC organization shares our passion for excellence and customer service. This has proved to be a very successful strategic growth initiative for us,” Jim explains.

Looking to the future, Jim highlights the company’s longer-term ambitions: “We recognize that we have to earn the right to grow both with our existing customers as well as a number of new customers in the emerging segments. This is true not only for the initial product sale but also for our aftermarket and field service organization.” With respect to its aftermarket organization, Jim shares that “we would also like to have a strong foothold in every shale basin in North America.” He concludes by stating that “while we are very excited about the future, we recognize that we must never become complacent nor lose sight of the fact that the company’s success is in the realization that our people are our only sustainable competitive advantage and that our focus must always be on taking care of our customers by giving them our best every day. Each and every order is simply the opportunity to earn the next one and the right to grow. If we continue to focus on these basic truths, we believe that our future will be as exciting as our past.”