BAEST

Simply the BAEST

Based in the Czech Republic, BAEST is an engineering company that specialises in the manufacture of components for the construction of building cranes, steel tanks, petrol service stations, bitumen and concrete mixing plants.

The company is strategically situated in Benesov, close to the important E55 and D1 motorways with access to the railway network. Formed in 2002 when it took over the business activities of BEST, s.r.o., another Czech company with similar production lines, it owns 30,000 square metres of production halls and is equipped with lifting and handling machinery of a capacity up to 50 tonnes.

The company’s primary activity is the construction of building cranes and related components, which began in 1991 and now accounts for over half of BAEST’s production line. The building cranes are used in civil engineering and renowned for their quality, reliability, economical operation and high speeds. BAEST manufactures other crucial components for cranes as well, such as towers, crane jibs, climbing devices, lower crane trucks and cross pieces, and provides clients with crane transport, after-market services, vocational training for employees and the assembly, and disassembly, of machinery throughout the Czech Republic.

Controlling director Frantisek Kulovany, jr. believes that its high-quality services and manufacturing efficiency are maintained through strategic investments in both technical and human resources: “Improvements can be achieved through constant enhancements in technology through investment and in training personnel to increase productivity. Training is a vital aspect of the company and we’re running a programme with the European Social Fund (ESF) organising in-house tuition for employees aimed at increasing output and flexibility.”

Since 2005, the company has achieved a 50 per cent increase in the production of components for building cranes and has plans to develop further: “We have already achieved the 50 per cent increase that we set out to achieve two years ago,” says Frantisek. “Now we would like to make some space for recruiting new customers within the branch of lifting equipment so we are currently operating within a capacity expansion phase, in order to serve new customers.” In 2006 the company increased its turnover over 50 per cent toward the year 2005 and average growth in turnover over past five years reaches 25 per cent yearly with more dynamic growth in exports.

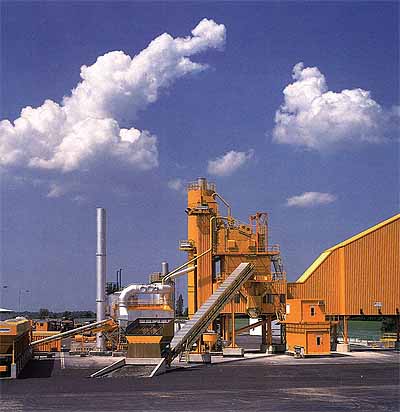

The construction of filling stations comprises 25 per cent of the company’s total production and these stations are mainly supplied to the domestic market in both industrial parks and small stations. BAEST is also involved in the production of the main components of bitumen mixing plants, silos for ready mixture, drying drum, granulating additives dosing, concrete mixing plants, silos to stock bulk material, four variations of fuel steel tanks, pressure tanks, building steel construction for filling station roofs and stainless steel products. The demand for quality is extremely high, especially in the production of gigantic steel constructions, so BAEST regularly invests 1.5 to 2.5 million euros in technology, machinery and equipment: “We work with highly advanced equipment such as flamecutting machines, welding robots and CAD-CAM systems,” reveals Frantisek. “Investments are extremely important but are long-term rather than yearly. The outlay in our staff coupled with the outlay in new technology in our core business – machining, welding and surface treatment – is the secret to our success. As a result, our strengths are high-quality products, flexibility in production, and reliability as a supplier.”

In 2005 the company experienced a 35 per cent increase in turnover, bringing the figure to 30 million euros. Export is a major factor of this success and the majority is focused on the US and Western European countries such as Germany, France, Italy, The Netherlands and Sweden. In recent years BAEST has also begun to participate within the markets of Poland, Slovakia and Austria and has built up to 25 filling stations in Ukraine. Its plan is to increase its Eastern European market share in Ukraine, Russia, Bulgaria and the Balkan states. Having been awarded SME´s Exporter of the Year in 2002 and 2005 by the Economic Chamber of the Czech Republic and Ministry of Industry, Frantisek feels such awards contribute greatly to BAEST’s continued success: “Exporting is key – approximately 92 per cent of what we produce is exported – and such awards are an excellent external evaluation of our success. They encourage customers to rely on us and create assurance.”

A key future priority is maintaining the quality of production and cost-efficiency, although the strengthening of the Czech currency presents a challenge that influences production. The country’s crown has been experiencing a steady rise of up to 27 per cent over the past five years and all of BAEST’s expenses are paid out in the Czech currency whereas the vast majority of its income consists of euros. Calculating this in relation to the increase of energy and labour costs can be demanding. “This is stressful for us, as is the potential lack of qualified personnel in the future and discontinuity of the economy globally,” states Frantisek. “We do, however, see good opportunities to enter new markets and integrate our company into international supply chains. I am confident in our abilities to offer quality in the field of industrial lifting or storage equipment and road building. Our vision is to be seen as a reliable partner for international customers and provide a punctual and reliable service, high quality and supplying at market acceptable prices.”

BAEST

Products: Components for building construction and petrol filling stations

Sites: Czech Republic

Employees: 400

www.baest.cz