Bihler of America Inc.

Bihler of America Inc. introduced Bihler manufacturing machines made in Germany to the United States 43 years ago, successfully integrating its fully automated systems into high-volume production facilities across a variety of industries. Since then, Bihler of America has grown to be a leading provider of precision, high-speed processes for stamping, welding and tapping of metal products, and a leading producer of multi-piece assemblies.

Bihler of America is a women-owned, independent entity supporting German slide forming technology to the North American market through different business units in multiple sectors including medical device, automotive, consumer products, 4 slide manufacturing and retailer of bungees. “Although Bihler of America distributes German manufactured machines with our advanced engineering capabilities, we have established our status as a market leader and an industry influencer,” Director of Sales and Marketing Max Linder explains. “Our customizable solutions directly enable our customers to set themselves apart and become industry leaders. In efforts to cater to our customers’ manufacturing needs, we are continuously developing the next generation of automation to maintain market leadership.”

Headquartered in Phillipsburg, N.J., Bihler of America recently opened a new 103,000-square-foot facility on its seven-acre campus and now has a combined total of 350,000 square feet of manufacturing space. As a provider of complex components manufacturing and machines, Bihler of America expanded its facility in response to the increased demand in custom manufacturing and automation projects.

The multi-functional facility built in partnership with IronHill Construction Management, part of the J.G. Petrucci Network, is fully operational for the production of the Bihler 4 Slide-NC, machine service, customer service, spare parts and tooling. It is also the primary manufacturing facility for the BihlerMED line of illumination-based medical devices and high-volume disposable battery packs for medical device applications.

“We added more than 100,000 square feet in manufacturing that we are eager to fill, are continuously increasing the headcount and manufacturing footprint as we are actively pursuing strategic alliances with customers to optimize our capabilities and improve our footprint in North America,” Linder says.

Manufacturing Solutions

Bihler of Germany provides basic pieces of equipment to Bihler of America that then customizes it to the North American requirements. “We are the integrator and customizing house for equipment used and the service agency for North America, which includes Canada, the United States and our U.S. customers’ locations in Mexico,” Linder explains. “I would say 90 percent of our classic customers ask us to do the customizing of equipment and use us later on as a service agency for future repairs, demands and upgrades.”

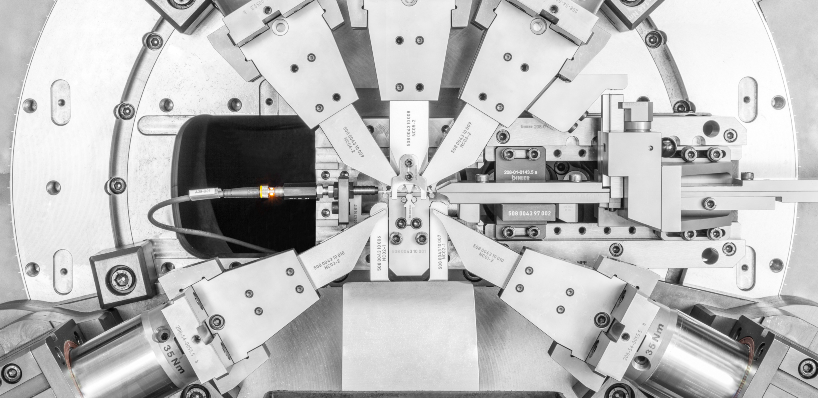

Bihler of America provides custom automation to meet virtually any manufacturing specification or machine requirement. Its team of experienced automation experts will create a tailored solution for customers’ most demanding manufacturing, assembly or packaging challenges. “At Bihler, we develop equipment to use in automation around the process for a product,” Linder explains. “We do this by using a complete building block system that is 100 percent standardized, but we have process modules we can configure in any set-up to adapt to a production process that is optimized for a certain product. The machine will be custom, but custom built out of standard block systems.”

A major advantage for Bihler of America is its skilled and experienced team of more than 10 designers who are capable of analyzing processes and providing alternative processes for customers. It also attributes its success to a strong sales team that can support its customers with new ideas. “When we introduce Bihler technology to a new customer, it opens their eyes that they can look at different strategies and we develop new turnkey solutions that improve their current status in manufacturing,” Linder explains.

Bihler prides itself on never being satisfied with what is accomplished. “We question, optimize and perfect the proven,” the company says. “In close collaboration with domestic and foreign strategic alliances, colleges, universities and research institutions, Bihler engineers continuously strive to develop new technically advanced manufacturing methods. Focusing on current and future market demands.”

Standard Equipment

Standard equipment is one of the alternative ways Bihler of America delivers manufacturing success to customers. The company is the exclusive representative of Otto Bihler Maschinenfabrik GmbH & Co. KG of Germany, which is known worldwide for producing standard equipment that is of the highest quality, reliability and performance.

Bihler of America offers cost-effective production systems for every application in the stamping or forming of parts, or in the production of complete assemblies. The company has mechanical and hybrid multi-slide machines, machining centers, automated servo-controlled manufacturing and assembly systems and more.

“The most important part of our manufacturing process is that whenever we see an opportunity in the industry for process improvement, we challenge the way it has been established with our technology now,” Linder explains. “For example, we look at material flow optimization, material usage optimization, process speed improvements or alternative processes that are unknown to one industry but known to others. That’s the advantage Bihler has – we are always addressing improvements based on the overall experience that Bihler has generated over the decades.”

Bihler machines can be customized with intelligent tool solutions, specific units, process modules and related flexible peripheral equipment to meet the precise application of its customers. Bihler and 4 Slide-NC machines can also be integrated with a customer’s existing equipment, creating complex manufacturing system.

4 Slide Strategy

“We revitalized an old technology and making it appealing to manufacturers today,” Linder explains. “4 Slide-NC launched about three years ago in the market and we have received an overwhelming response. It’s a competing process to overhead presses and we revitalized all the slide equipment that had been abandoned from OEMs for about 30 years. There was no one  left to support it and no new equipment has been built, so we revitalized technology with highly efficient servo systems.”

left to support it and no new equipment has been built, so we revitalized technology with highly efficient servo systems.”

The 4 Slide-NC sector is an interesting one, Linder says. “It’s a very common and established process,” he adds. “We did a market analysis and there are about 30,000 active machines in the industry still today. We had one customer that ran 70 of the mechanical 4 Slide machines and replaced those with 3 of our 4 Slide-NC machines and still increased productivity. What for years was done on 70 machines can now be done with just 13, offering much higher capability and better quality, consistency and planning ability because the machines aren’t going down. Some of those 70 machines were backup machines and to avoid shutdown, which is unacceptable in today’s automotive machine industry. The customer upgraded his technology and has been very successful.”

In November, the company will launch an upgraded version of its 4 Slide-NC at FABTECH 2019 in Chicago. “It’s an upgraded version of the machine that incorporate lessons learned. We conducted a study to learn what we could improve, adding new features and functions where needed.”

Quality Assurance

Quality is always expected among its customers and is never compromised at Bihler of America. “Our credo is that you always need to make the first part exactly the same as the 15 millionth or 200 millionth part,” Linder says. “We have a huge advantage in the industry, providing consistency, stability and process capability over extremely high production volume.”

When it comes to quality, Bihler of America approaches it by monitoring process. “The normal objective in the industry is monitored quality,” Linder explains. “I’m approaching it by monitoring the process parameters and using them as indicators that the process is stable. That reduces quality inspection by a lot and offers much more consistency. The ability to react to parameters and adjust motion profiles ensures long-term capability and quality for product way more because you’re ensuring the process is stable rather than controlling the product we are producing.”

To ensure quality, Bihler of America continuously improves its equipment. “It’s not a generational change so much that we are supporting equipment that was built for 40 years ago,” Linder says. “If you bought a Bihler machine 40 years ago that was completely mechanical, you can a buy machine today that your existing tools will fit on and you can run them. It allows customers to run old tools today significantly faster through our servo innovation that changes the layout of the machine automated. We never leave our customers alone. If you go with Bihler, that’s a lifetime of equipment and service, refurbishing and upgrading of controls.”

Being part of “Bihlership,” customers benefit from the strong partnership with Bihler. “From the initial inquiry, production-aligned product design, detailed project studies, sample parts, complete tooling solutions, and far beyond machine installation and commissioning, Bihler is at your side,” the company says. “You benefit from continuous technology developments and the transfer of Bihler Know-How. WE pass on our knowledge and experience through design consultation, welding tests and various training and project planning seminars. Our perfectly tailored support guarantees maximum productivity of your Bihler machine throughout its entire lifecyle.”

Looking to the Future

As Bihler of America’s mission is to keep its customers the leading company in their respective industries, it continues to look to challenges of the future and develop solutions. One of the biggest concerns among manufacturers today is the aging workforce for mechanical production equipment. Bihler of America is addressing that challenge by making its equipment more attractive to the younger generations.

“We have one customer with 700 employees and over the next six years, 250 people in that workforce are retiring, which are huge alarming problems for the industry and we try to address this with new generation of automation and production equipment that is more attractive to the next generation,” Linder explains. “Our machines have touch panel screens to control it like a computer or touch screen phone, which appeals to millennials and the next generation of workforce coming out of school.”

The company also sees a level of uncertainty and hesitation to make decisions among manufacturers today because of the current economy and political climate. However, Bihler of America’s outlook is positive because customers concerned with minimum wage increases and the aging workforce are moving towards automation companies.

“They are looking to Bihler to stabilize an important part in the equation and in the manufacturing of a part,” Linder explains. “Everyone is looking for stability and they can’t get it from the economy and politics, so they need to have it in manufacturing. We see this as a very good trend for Bihler and are not as concerned about economic shifts because automation demand will continue and even more so during a slower economy.”