Blending innovation and engineering know-how, Gulmay powers the next generation of X-ray tech

Founded over 40 years ago, Gulmay is a market leader of X-ray power supply technology. As Operations Director, Andrew Platten, explains: “Gulmay produces highly stable power supplies for use in the X-ray industry. We work with clients in the medical research and non-destructive testing industries, as well as security companies.

“Our first X-ray prototype system was produced in 1978, with the business being formally established in 1980. Our first factory was in Ashford, Middlesex, and from there we produced our first Microfocus generator. This was introduced to the product line in 1985 and remains one of our top selling products to date.

“From there, the product line expanded rapidly. We introduced a variety of controllers and generators, while continuing to develop our technology to remain at the forefront of our industry. We became ISO certified in 2000 and broke into the US market in 2008.

“From there, the product line expanded rapidly. We introduced a variety of controllers and generators, while continuing to develop our technology to remain at the forefront of our industry. We became ISO certified in 2000 and broke into the US market in 2008.

“Since being founded in the 1980s, the business has grown considerably. Today, our operational footprint consists of three regional offices, in the US, Germany, and China, and two sites in the UK: the headquarters in Surrey and our encapsulation facility in Cornwall.

“In terms of our manufacturing network, we produce some products in China and the US, which primarily serve international markets. We’re proud to say that all of our industry-leading power supplies and controllers are still manufactured here in the UK. It’s the operational hub of our business, and most of what we do is driven by our managerial and manufacturing teams across England.”

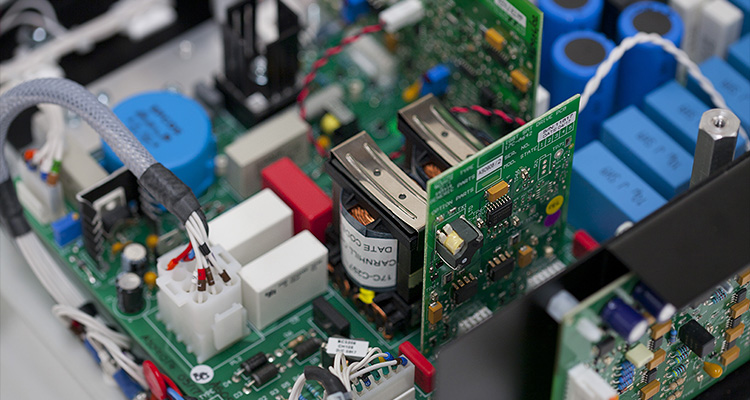

As a technology-driven enterprise, Gulmay offers an industry-leading range of X-ray solutions. “We provide products in six key categories: X-ray generators, industrial X-ray tubes, X-ray controllers, X-ray subsystems, tube coolers and chillers, and generator accessories. We still sell our flagship product, which has remained an industry leader for over 40 years. Of course, since that first prototype, we’ve developed our technology, and our updated and improved UD generator will be available on the market later this year.

“The new generators come complete with all-new electronics and smaller tanks. They are more compact, lighter, and have a wider range of features for the customer to use. They are also designed to offer customers system health monitoring, with patented, active filament monitoring technology that will allow customers to monitor X-ray tube filament lifetime and plan preventative maintenance in advance,” Andrew details.

Technology is also a huge focus for Gulmay, helping the business improve manufacturing processes and supporting its sustainability mission. As Andrew reveals: “We’ve recently invested in a new winding machine at our production facility in Newquay as well as improved ovens to aid our curing process and a new CNC machine to increase machining capacity, andwe’re already seeing very exciting results. In Byfleet we’ve invested in an oil processing machine from Swiss firm Micafluid AG, as well as specialist lifting equipment to improve our packing process. Embracing new technology has always been central to Gulmay’s mission and success, so it’s likely we’ll continue to invest in new machinery, especially when the equipment makes a tangible difference to our product.

“New technology can contribute to the prosperity of our business in different ways, for example, we’re aiming to install solar panels on our factory in Newquay to reduce our emissions. Sustainability is a key issue, and we all have a part to play in ensuring our operations are planet friendly.”

reduce our emissions. Sustainability is a key issue, and we all have a part to play in ensuring our operations are planet friendly.”

Ongoing investment into research and development allows Gulmay to offer innovative, industry-leading solutions. The company’s strategy for continual improvement brings together market research, customer relations, and advanced engineering. As Andrew discusses: “Making contacts within the industries we serve is vital, as it allows us to target our product development to meet the needs of our customer base.

“Our networking strategy includes attendance at trade shows, creating an online presence through social media, especially LinkedIn, and building strong relationships with contacts throughout the industry.

“Expanding our horizons and speaking to people who use our products daily allows us to gain a comprehensive view of our existing range. Our existing product range is designed to address the broad range of challenges our customers are facing, but our modular approach to high voltage design means when required, were able to adapt our designs to meet new challenges.”

Between new product launches and green initiatives, Gulmay is set for success. Looking ahead, Andrew considers what’s next for the business: “The first half of 2025 has been incredibly promising for us here at Gulmay. We’ve seen an uptick in sales, and we’ve definitely turned a corner in terms of our new product development. I hope to see things continue to move in the right direction, especially with the launch in a few months.

“Further afield, looking four or five years into the future, I’d like to see the company continue its trajectory of steady and sustained growth. We’re working hard to expand our product portfolio with new high-power platforms and updated chassis designs, which build on the strength of our pioneering X-ray power supplies. These next-generation solutions reflect our ongoing commitment to innovation and are developed with our customers’ evolving needs in mind,” he concludes.