Brown McFarlane has evolved from scrap trading to a global leader in processed steel

Building on over 135 years of history, Brown McFarlane is today a leading carbon and stainless-steel plate processor and stockholder. It delivers high-quality processed components to a global customer base across a wide range of industries. Managing Director Tony O’Reilly shares a more detailed overview, as with over a century of history, the company has evolved extensively: “Originally established in 1889, the business has its roots in Glasgow, Scotland. Founded by a merchant seaman called Albert Richard Brown, it began trading scrap on the docks of the Clyde. The founder was one of the very few non-Japanese people to be awarded the Order of the Rising Sun for services to the Japanese government for supporting them with shipbuilding. Following that collaboration, he founded Brown McFarlane, originally trading scrap and then trading plate material.

“The business developed from just trading plate and started offering a processing service. In the 1980s, the company expanded its facilities beyond Glasgow, establishing a site in Stoke-on-Trent. In the early 1990s, the company decided to concentrate on the main processing site in Stoke-on-Trent, mainly because of the logistics benefits, due to its central location. To this day, though, we still have a sales office in Glasgow where the headquarters and owners are based.

“The business developed from just trading plate and started offering a processing service. In the 1980s, the company expanded its facilities beyond Glasgow, establishing a site in Stoke-on-Trent. In the early 1990s, the company decided to concentrate on the main processing site in Stoke-on-Trent, mainly because of the logistics benefits, due to its central location. To this day, though, we still have a sales office in Glasgow where the headquarters and owners are based.

“By the mid-1990s, the business evolved further, becoming a profiling business. As this grew, much more of our business became processing. Today, 95 percent of the plates we pick up are processed in some way, and generally we perform multiple processes, not just one. As a plate business, we’re recognized for having premium stock, including many of the obscure grades. We will sell regular commodity products for customers that want them, but generally, our specialty is higher-grade, premium, specialist steels.

“Currently, a large portion of our revenue comes from stainless steel as well as mild steel. Our plates are generally wider and longer than most stockists – we keep standard plates in 12-metre lengths and widths up to four meters, and customers can have any multiple of that. It’s our depth of stock that really sets us apart; we have a large and deep range of premium grades. We’ll cut it down to any size and shape the client requires. Then we add value by providing further downstream processing if required.”

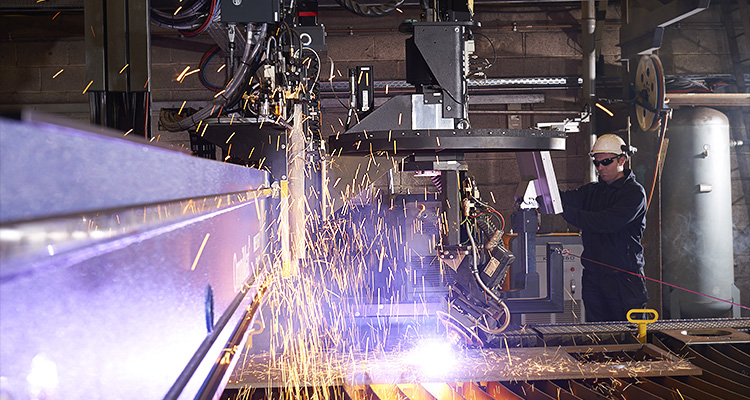

As Tony notes, the business has put extensive work into being able to offer these value-added products, and they are a big differentiator that set it apart in the market. “We have varied processing equipment from gas cutting and drilling to plasma cutting, laser cutting, and water jet cutting. More recently, we’ve added a machine shop as well, providing us with the capabilities to perform any additional processing a client wants. Our machine shop has enabled us to become much more of a one-stop shop for fabricators and for anybody dealing in steel. Instead of raw materials, a customer gets a semi-finished or a finished component delivered to site. We’ve spent a lot of time, effort, and energy growing these value-added services. Our most recent investment is a press-brake, which gives us the additional capability to bend material up to 25 millimeters thick. To complement our extensive stock range and processing capability we have some very experienced and knowledgeable staff.”

The company has experienced record growth in recent years. Tony reflects on the factors that have driven this success: “Prior to the pandemic, we went through a reorganization and restructuring process. We invested in a new laser machine, reconfigured our other existing equipment, and made infrastructure changes. We made investments in plant and equipment with the aim of increasing efficiency.

“Another key component is that we have adapted to a changing market. Brexit and the pandemic probably helped us as a business in some ways. The war in Ukraine, though, produced significant challenges for many businesses, including for supply chains; fortunately, due to our long-standing relationships, we were able to maintain supply and continued to offer uninterrupted service to our customers. We’ve invested in the right areas, and we’ve made some good strategic decisions that have transformed the performance of the business.”

Moving on, Tony highlights how the company’s sustainability efforts have provided additional benefits to the business: “The first solar installation was in 2019; we installed 1160 solar panels on our main building. It was initially thought to be a five-to-six-year payback that actually turned out, with the rising energy charges, to be less than three years, which was fantastic for us. In a market where energy costs continue to rise, it makes perfect sense. So, when we built the next warehouse for the machine shop, which was completed in 2023, we put solar panels on that one as well.”

Looking to the future, Tony concludes with an outlook for the rest of the year and beyond: “The year ahead will be challenging, as the market does seem much more difficult, both in terms of volume and margin opportunity. This is the time when we have to roll our sleeves up. We have to be smarter commercially and more proactive in the market. We’re well placed to do that with the products and services we offer; our brand and reputation in the market will see us through. The company is in a healthy position financially and as I always say, ‘any business can make money in a good market, but it takes a good business to make money in a poor market.’

“In five years, I would hope to see even more of our apprentices taking substantive roles and a succession plan in place for the long-term sustainability of the business. I want us to continue to innovate and find solutions for our customers. Continuing to modernize and be recognized as a capable and ethical partner for projects as well as a reliable and consistent supplier of day-to-day steel requirements that fit with individual customer needs. I am proud of the transformation and the success we have enjoyed. Now is the time to invest further and to ensure that Brown McFarlane continues to be recognized as a premier plate processing supplier,” he concludes.