Building the bridge to Industry 5.0. By Anupam Singhal

It is no secret that the manufacturing landscape is undergoing rapid change. Amid a shifting geopolitical environment, rising input costs, and unpredictable demand patterns, manufacturers across industries are facing increasing complexity. Industries such as automotive, transportation, electronics, and chemicals stand to face significant disruptions.

Reimagining intelligence in manufacturing

Industry 4.0 brought tremendous advancement in automation, sensors, and connectivity. However, in today’s environment, the need is not just to connect machines, but to enable them – and the people who operate them – to sense, decide, and act in real time. Industry 4.5 doesn’t replace Industry 4.0; it elevates it. It’s a necessary evolution that brings intelligence to the edge, enabling a new generation of factories that are not only connected, but cognitive.

Industry 4.5 is not a detour; it is a deliberate, necessary phase of evolution. It advances the foundations laid by Industry 4.0, amplifying intelligence, adaptability, and human-centricity. It’s a space where digital twins, generative AI, physical AI, and agentic AI converge as enablers of transformation.

Digital twins: The living blueprint of the future

At the core of this transformation is the digital twin. Once a peripheral technology, it has now emerged as a strategic asset. Today’s digital twins are intelligent, real-time data fabrics that simulate, predict, and optimize everything from individual assets to entire supply chains. They enable enterprises to model future scenarios with high precision, anticipate disruptions, and take proactive decisions. In essence, digital twins transform how manufacturing thinks and acts.

Flexible factories, smarter outcomes

One of the defining shifts Industry 4.5 brings is the move from centralized, capital-heavy production to flexible, distributed factories of the future. They’re not just smaller, they’re smarter with intelligence embedded at every node. These micro-factories are locally relevant, digitally enabled, and AI-powered, offering agility, customization, and resilience at scale. They are also more sustainable, helping reduce the carbon footprint by bringing production closer to demand.

Bridging the physical and the cognitive

As GenAI accelerates capabilities in design and simulation, and Physical AI drives automation on the shop floor, the convergence of both – through digital twins – is unlocking new possibilities. The real power lies in making intelligence actionable. Agentic AI takes it a step further by enabling self-learning, autonomous systems that evolve continuously. The result is a living, learning factory that self-corrects, adapts, and improves, with humans firmly at the helm of decision-making.

Human + machine: A new collaborative model

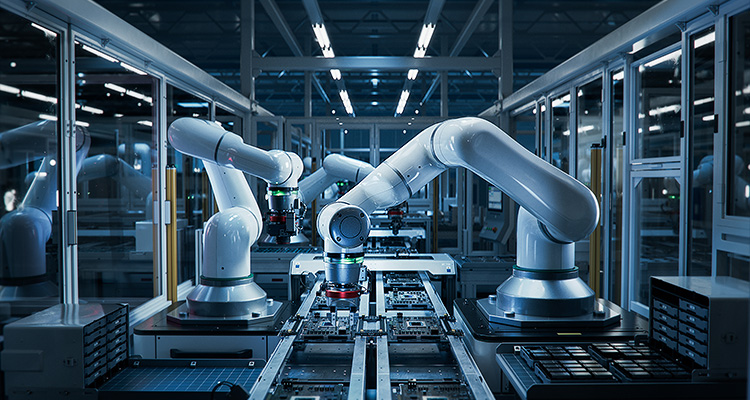

Despite the rise of intelligent machines, the future of factories remains profoundly human-centric. The goal isn’t to replace people, it’s to amplify their potential. Digital twins and AI copilots provide faster, more precise decision-making. Cobots – collaborative robots – support humans in repetitive or hazardous tasks, freeing them for more strategic, creative responsibilities. It’s a partnership of trust and augmentation, not substitution.

Design for intelligence

Design for intelligence

As enterprises advance, the focus shifts from merely adopting new technologies to embedding intelligence into the core of their operations. At TCS, we term this methodology ‘Design for Intelligence’ – a strategy where systems are crafted not only to perform but to sense, learn, and adapt continuously.

Leadership

As enterprises embrace Industry 4.5, a new leadership style is also emerging, one rooted in subtle executive presence. It is no longer about commanding scale but orchestrating intelligence. Leaders of the future factory will enable systems that sense and adapt; guide teams through complexity; and empower decisions that drive sustainability, resilience, and human value.

The path ahead

As manufacturers look ahead, the question is no longer just about adopting digital technologies, it is about designing intelligence into the very fabric of their factories. Industry 4.5 is the bridge to that future, one that enables enterprises to be not just efficient, but truly future-ready.

This shift toward intelligent, distributed production is also laying the groundwork for ‘lights-out factories’ – autonomous, self-operating facilities capable of running with minimal human intervention. While the vision is compelling and the jury is still out on when this will become mainstream, the momentum is undeniable, and forward-looking enterprises are already laying the foundation for this next frontier.

Anupam Singhal

Anupam Singhal is President – Manufacturing, TCS. TCS Manufacturing stands at the forefront of industry operations, setting new benchmarks and driving transformation with advanced technologies. Its proactive and innovation-led approach is reshaping the manufacturing landscape, leading the change, and distinguishing itself as an industry leader.

Design for intelligence

Design for intelligence