C. L. A. Tools Ltd

Well equipped

C.L.A. Tools Ltd is a C.N.C. manufacturing company with a proven track record of quality and service, employing highly trained, skilled and experienced staff

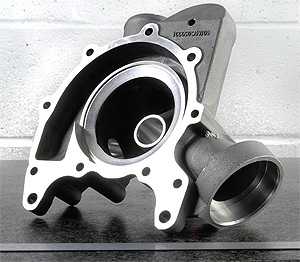

C.L.A. Tools Ltd is a family owned business, currently into its second generation, providing subcontract precision engineering work for its customers, making parts for a number of industries and companies. The ISO-accredited company supplies the automotive industry including Formula 1, plus other sectors such as hydraulic and pneumatic, railway, agricultural, aerospace, and MoD. The company does a lot of prototype work, often in conjunction with casting companies and their customers, proving machining processes prior to volume production. C.L.A. offers expertise in the design and manufacture of fixtures to hold and ensure precision machining of castings. With recent investment into machinery and some important new people being brought on board, the company is looking to improve its core capabilities and also expand into higher volume work.

Within the past few years C.L.A. Tools has made large-scale investments in machinery and personnel at the company. These developments will improve the quality and range of work that the business is able to perform, and managing director Melanie Flinn discussed this: “We have invested in two five-axis machining centres, and we have another one pencilled in for next year. As a part of this improvement we ensure that we have all the supporting software and training. This also means finding the right people to use these machines to their optimum level, working with the machine tool supplier to ensure familiarity with the latest technology. The machines give more accuracy and speed, and in particular will help with the work we do in prototyping – that can often be very complex.” Adding these new machines to the company’s range shows its intent, and that it is willing to use its own funds to support growth at a rate that is maintained by its sales. It always carefully considers what the best long-term move is for the business, and as a family run company, sustainable long term growth is the focus.

Within the past few years C.L.A. Tools has made large-scale investments in machinery and personnel at the company. These developments will improve the quality and range of work that the business is able to perform, and managing director Melanie Flinn discussed this: “We have invested in two five-axis machining centres, and we have another one pencilled in for next year. As a part of this improvement we ensure that we have all the supporting software and training. This also means finding the right people to use these machines to their optimum level, working with the machine tool supplier to ensure familiarity with the latest technology. The machines give more accuracy and speed, and in particular will help with the work we do in prototyping – that can often be very complex.” Adding these new machines to the company’s range shows its intent, and that it is willing to use its own funds to support growth at a rate that is maintained by its sales. It always carefully considers what the best long-term move is for the business, and as a family run company, sustainable long term growth is the focus.

All of these investments are made with a long-term business plan in mind. There are no short-term solutions with C.L.A. Tools as the company places great value in being a stable, reliable, and trustworthy family business. It takes an honest approach to its work, and believes in transparent dealing with its customers. This is an ethos that stems from the family values set out by its founders and current director – that place an emphasis on gradual growth, job satisfaction and security for employees and being a reliable and trusted choice for customers. Melanie discussed the values and strengths that come from the company’s family background: “It of course offers continuity, and along with that, financial stability over many years. The company was established in 1974 by my parents, and about two decades later in 1992 they had a purpose built factory made, the benefits of which continue to this day. Also, due to the nature of our company everything has always been funded from within; everything is owned outrigh . The company doesn’t carry any debts, and I think this is a major plus.” Financial security allows continuous investment including the constant monitoring and upgrading of systems underpinning the ISO 9001 and ISO 14001 accreditations. Melanie explained: “These systems ensure all of our production processes are managed efficiently, from certified receipt of materials into the factory through to the on-time delivery of accurate parts supported by inspection documentation tailored to the customer’s needs.”

Another feature of the family business is the importance it places upon its staff and how it engages with them and C.L.A. Tools prioritises finding the right people for the role and for the company. The importance of its work force was something that Melanie highlighted: “It was essential to find good programmers and engineers who are capable of doing various aspects of  the job – and we have a really good team in place. We have a great mix of time-served toolmakers and engineers, as well as new people coming in and learning from those more experienced members of the team. Unlike many of the big companies where there might be an office full of CAD engineers who never go onto the factory floor, as a smaller company we have a flexible group of CAD engineers who are able to apply their expertise in a number of areas.”

the job – and we have a really good team in place. We have a great mix of time-served toolmakers and engineers, as well as new people coming in and learning from those more experienced members of the team. Unlike many of the big companies where there might be an office full of CAD engineers who never go onto the factory floor, as a smaller company we have a flexible group of CAD engineers who are able to apply their expertise in a number of areas.”

C.L.A. has invested in state-of-the-art CMM inspection facilities and the latest software and training. Melanie discussed some aspects of this: “The temperature-controlled CMM inspection facilities mean we can certify our accuracy and produce tailor-made reports such as ISIR and PPAP, according to customer demand. This is in addition to our usual first-off and in-cycle checks by our operators.”

One of the characteristics that runs through C.L.A. Tools, and stems from being family owned, is flexibility and transparency. This is extended to the relationship it has with customers: “I think something that really sets us apart is that we respond quickly and positively to what a customer needs, because often when you are working at a prototype level designs can change and develop and it is how you respond to these changes that is important. We are good communicators. We are very open with customers, working with them to address and resolve any problems,” Melanie stated.

C.L.A. Tools already had good manufacturing facilities, machinery and staff. Now it has evolved to a new level of machinery, and more highly skilled personnel. The company is able to offer faster and better versions of its traditional services, but has diversified and widened its market and customer reach. For all of these reasons, the future for C.L.A. Tools looks positive, and with an attitude that runs throughout the family owned company of pursuing steady, stable, and consistent growth, it looks set to further improve its position

C. L. A. Tools Ltd

Services: Subcontract precision engineering