Celebrating its centenary, Ashton & Moore continues to deliver cutting-edge solutions that stand the test of time

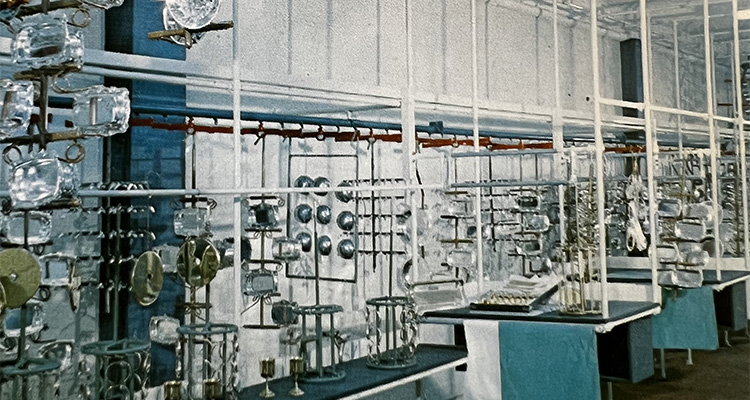

From electroplating and anodizing to conversion coating and passivation, Ashton & Moore’s comprehensive suite of core services is designed to protect, enhance, and perfect products with precision and excellence. Established in 1924, the company is an independent self-contract surface treatment house, working primarily in the aerospace and defense supply chain. “We are typically contracted by Tier 1, 2 and 3 suppliers,” begins Dr Keith Tucker, Joint CEO. “Components are free issued to us; we apply the required coatings to a high aerospace standard and then return them. This year, we’re proud to be celebrating our centenary. Founded by Lesly Ashton and Chris Moore, the company was started to color metal components for the jewelry industry. It then went on to develop the process of bulk anodizing in the 1930s and help supply rivets for the new breed of aluminum skinned aircraft, such as the Hurricane and Spitfire. In the 1940s and 1950s, the company flourished, and moved more towards aerospace and defense, becoming a recognized leader in metal finishing.

“In the 60s, following a project with Kodak that didn’t come to fruition, the company was bought out and owned by Wandsworth Electrical until 2005 when as Technical Director, myself, the then Works Manager and the Sales Director executed a management buyout (MBO), making Ashton & Moore once again an independent family-owned business. A few years later, we performed an ambitious fully self-funded move of our current 38,500 square-foot modern facility in Hockley, Birmingham, over an 18-month period. We have been at this site ever since and have grown to employ approximately 84 people. Some of our people have been with us for as long as 30 or 40 years. We’re about as close as you can get to a family-owned company these days. Since the MBO, we’ve grown the business by almost 500 percent and have become a world leader in the finishing and non-destructive testing of components in the aerospace and defense sectors, as well as other high-end engineering fields,” Keith shares.

“In the 60s, following a project with Kodak that didn’t come to fruition, the company was bought out and owned by Wandsworth Electrical until 2005 when as Technical Director, myself, the then Works Manager and the Sales Director executed a management buyout (MBO), making Ashton & Moore once again an independent family-owned business. A few years later, we performed an ambitious fully self-funded move of our current 38,500 square-foot modern facility in Hockley, Birmingham, over an 18-month period. We have been at this site ever since and have grown to employ approximately 84 people. Some of our people have been with us for as long as 30 or 40 years. We’re about as close as you can get to a family-owned company these days. Since the MBO, we’ve grown the business by almost 500 percent and have become a world leader in the finishing and non-destructive testing of components in the aerospace and defense sectors, as well as other high-end engineering fields,” Keith shares.

“Our accreditations not only validate our expertise and capabilities but also provide our clients with the assurance that they are partnering with a trusted and reputable organization. We work closely with our customers and their clients to improve our products and services. We are involved in looking at more environmentally friendly surface finishes. For instance, the big drive currently is to reduce the amount of hexavalent chromium from some of the finishes. As you can imagine however, where aircraft are concerned, it’s very difficult to change legacy processes quickly. Our customers’ customers need to be happy with any changes or suggested implementations. New processes require extensive testing and validation prior to being signed off. It some cases, it can take decades to implement new ways of working. Indeed, many of the existing processes we carry out already increase the longevity of components and enhance engine efficiency.”

Recently, Ashton & Moore has been investing in technology to enhance cybersecurity and supply chain resilience. Similarly, its JOSCAR accreditation demonstrates compliance, minimizes duplication, reduces barriers to entry and improves the ease of doing business in the defense and aerospace sectors. Alongside investment in technology, the company is also investing in employees for strategic succession planning.

“Over the last few years,” Keith continues, “we have been trying to share some of our legacy experience and expertise, giving our managers greater responsibilities and empowering them to oversee certain aspects of the business. We’re also recruiting externally to bring new talent and expertise onboard. We’ve recently recruited someone who will take over from me and my fellow director, Mark. After 25 years or so of being immersed in the organization, it’s a new experience to be thinking about winding down and stepping back from day-to-day operations.

“We’re constantly trying to maintain and enhance our capabilities to keep up with our clients’ requirements. In terms of supplier partnerships, we’re often dictated by our customers’ needs for specific finishes. While we invest in modernizing our equipment, we tend to deliver low-volume, high-quality or niche processes, so many of our services are labor intensive. As such, we try to offer enhanced value. Our non-destructive testing for example, when combined with our finishing capabilities, offers aerospace, defense and other specialist manufacturers the opportunity of single source procurement.

capabilities, offers aerospace, defense and other specialist manufacturers the opportunity of single source procurement.

“Looking to the future, alongside succession planning, we will continue to focus on improving operational efficiencies. As I mentioned briefly, our operations are weighted towards manual processes; so much so that labor amounts to approximately 50 percent of our overall operational costs. With the cost of labor increasing, it’s becoming ever more evident that we need to focus on what we’re good at, where we make a profit, and where we’re most efficient. The pandemic really reinforced this for us. Turnover is vanity, profit is sanity, but cash is king. It’s not all about profit; it’s about being efficient and keeping the company viable and sustainable.

“In the coming years, I hope we’ll still be prominent in the aerospace and defense sectors. I also anticipate the company being more self-sufficient, so that Mark and I can step back and allow that legacy experience and expertise to shine through. Hopefully, we’ll still be at the forefront of some of the processes that we offer and those new, more environmentally sustainable processes that we’re putting in place will be signed off and ready to service our customers in the future. I believe one of the strengths of our company lies in our technical experience and practical knowledge, which shouldn’t be undervalued,” Keith concludes. “I think it’s difficult in this current global environment to remain competitive. While I don’t necessarily worry about the future of Ashton & Moore, I do think it’s crucial to champion UK manufacturing and support the aerospace and defense sectors. Ultimately, we want to continue to deliver impeccable finishes that not only meet but exceed the expectations of our clients.”

For the past 100 years, Ashton & Moore has been at the forefront of innovation, setting the standard for quality, precision, and reliability in every finish. As the company commemorates this milestone, it looks forward to the next century of pushing boundaries, pioneering new technologies, and continuing to elevate the standards of surface perfection.