Championing progression and performance, Lyman Products continues to push the boundaries of firearm fabrication

Brands that perform: three words that define Lyman Products. With a legacy spanning over 145 years, Lyman Products (Lyman) has remained at the forefront of innovation, earning a stellar reputation for pioneering advanced technologies and prioritizing performance. Stocking a comprehensive portfolio of firearms and accessories, the company has eight different brands under its belt, each offering something special to adhere to its customers’ needs.

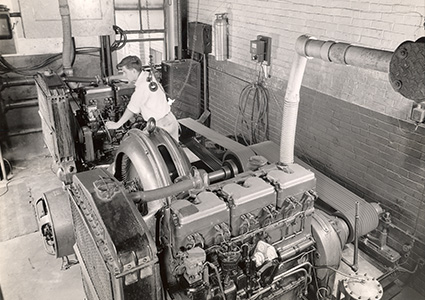

“Lyman Products was incorporated in 1978 under private ownership in an acquisition led by James F. (Mace) Thompson,” begins Rick Ranzinger, President of Lyman Products. “Mr. Thompson was a senior executive of the Leasure Group, a California based company holding numerous brands in the outdoor industry, including Lyman, Sierra Bullets, and High Standard Firearms. Lyman’s history began in 1878 in Middlefield, Connecticut, as a manufacturer of metallic gun sights. As the company grew in the 1900’s they added reloading equipment through the acquisition of the Ideal Tool Company and later began the manufacture of rifle scopes.

Products. “Mr. Thompson was a senior executive of the Leasure Group, a California based company holding numerous brands in the outdoor industry, including Lyman, Sierra Bullets, and High Standard Firearms. Lyman’s history began in 1878 in Middlefield, Connecticut, as a manufacturer of metallic gun sights. As the company grew in the 1900’s they added reloading equipment through the acquisition of the Ideal Tool Company and later began the manufacture of rifle scopes.

“Today, Lyman Products remains a private corporation that manufactures and distributes quality products within the shooting sports and metal finishing industry under established brand names. Our corporate mission is to establish performance in all product lines and be a leader and innovator. Lyman’s growth has come from a combination of organic product development and acquisitions. In 1987 Lyman acquired Raytech Industries, a leader in vibratory polishing and metal finishing. In 1996, Lyman began a series of further acquisitions to broaden its presence in the shooting sports arena. Pachmayr, a historic name in handgun grips and recoil pads was acquired in 1996, followed by TacStar, a leading supplier of aftermarket accessories for shotguns. In the period between 2002 and 2008 Lyman further acquired Trius Clay target traps, Butch’s Gun cleaning accessories and A-Zoom Safety training rounds.

“To expand in the reloading market, Lyman acquired Mark 7 of Fort Myers, Florida in 2019. Mark 7 was relatively new and offered product innovation and automation that was new to the industry. After reorganizing the company and assuming the parts manufacturing in Connecticut, Mark 7 expanded in both the retail and commercial markets with innovative and patented product lines. In 2023, Lyman expanded the Mark 7 facility in Fort Myers to meet the growing demand of the brand and service needs of its customers.”

The development of the Mark 7 brand is a key element in Lyman’s growth strategy going forward. Offering a full line of innovative reloading presses, Mark 7 excellently enhances Lyman’s existing portfolio, particularly as the company sets to reintroduce its own brand products, such as its new Titan series.

Anthony Parillo, Vice President and General Manager of the Mark 7 Division elaborates: “With the just released Titan series we have increased our product offering in the commercial segment. We plan to continue growing the commercial line with specialized accessories, new sensing technology and broadened caliber support. An entirely new control system was developed for the Titan series which will be applied across all of Mark 7’s machines with the goal of making automated reloading more economical and accessible from the shooting enthusiast to higher volume ammunition manufacturers.”

When it comes to research and development (R&D), customer feedback is paramount. Lyman’s R&D cycle is centered around innovation, improvement and industry excellence. Analyzing current trends, competitor offerings and user demands, Lyman conducts extensive market research and feasibility studies, evaluating the technical and economic viability of any potential product, to ensure that it can provide only the very best solutions for its customers. Before hitting the market, every initial prototype is meticulously developed, undergoing rigorous in-house testing for performance and reliability until the final product is perfected.

When it comes to research and development (R&D), customer feedback is paramount. Lyman’s R&D cycle is centered around innovation, improvement and industry excellence. Analyzing current trends, competitor offerings and user demands, Lyman conducts extensive market research and feasibility studies, evaluating the technical and economic viability of any potential product, to ensure that it can provide only the very best solutions for its customers. Before hitting the market, every initial prototype is meticulously developed, undergoing rigorous in-house testing for performance and reliability until the final product is perfected.

“Much of our product development is driven by pain points in the reloading process identified by our customers,” explains Anthony Parillo, Vice President and General Manager of the Mark 7 Division. “We developed the product specifications for the Titan based on how our customers were using our Revolution machines, which was in specific configurations, processing, priming, and loading rather than one pass reloading. This led to adding stations and making the press double feed capable to increase the throughput in these configurations while at the same time lengthening the stroke of the machine to allow for larger calibers.”

“We closely monitor our competitors and regularly review market data and industry reports to stay ahead,” adds Peter Lier, Director of R&D. “Many of our R&D engineers and staff are passionate shooting sports enthusiasts, which gives us valuable first-hand insight. A significant number of our innovations stem from identifying ways to improve efficiency, precision, and overall user experience in reloading and other aspects of the sport. We also place strong emphasis on customer service feedback, using it both to enhance existing products and to inspire new ideas.”

To uphold these high standards of innovation, Lyman offers a wide range of machining capabilities to support complex, high-precision manufacturing from its 100,000-square-foot, state-of-the-art facility in Connecticut.

“Our in-house CNC shop features 24 machines, from Swiss-style CNCs for small, high-tolerance parts to mill-turn machines, vertical mills, and precision lathes,” shares Stephen Kelly, Vice President of Operations. “We can efficiently produce everything from intricate components to large parts with tight tolerances and superior finishes. This diverse mix of equipment allows us to efficiently manage our high-mix, low-volume production while minimizing lead times through in-house manufacturing.”

In 2025, the manufacturing industry and current economic climate is tumultuous, battered by challenges from all angles. However, with over a century of experience and expertise, it is evident that Lyman is a business built for the future, adaptable to any era. With its dedicated, talented team at hand, Lyman is well positioned for furth growth as it continues to adapt and evolve with the markets, impressing its customers with cutting-edge designs and top-quality manufacturing.

“2025 will be a year of challenge as we face changing events, particularly in our supply chains. Regardless of where the current tariff issues land, it will force permanent changes to most companies, particularly in supply chain sourcing and manufacturing efficiency and readiness. Several years ago, we already made the decision to migrate some of our imports into other countries to avoid risks with China,” Rick reveals. “In the US, most of our R&D efforts will be focused on US manufactured products and further innovation in our product lines. We see AI, intellectual property and robotics playing a major role in the next five years as we become the go-to source for automation for consumers and small businesses within the reloading industry. We plan to focus on building on our current brands rather than acquiring new ones but will be closely looking at opportunities for new partnerships or acquisitions with key suppliers and subcontractors to improve our operating costs and margins.

“Above all else, however, we need to continue to supplement our organization with strong managers with new ideas and dynamic leadership qualities. Our employees are our most important resource,” he finishes.