Concurrent Technologies

Embedded success

The computer boards designed and manufactured by Concurrent Technologies are used by many of the world’s leading integrators within the defense, security, telecommunications, transportation, medical and industrial markets

Concurrent Technologies Plc, a public company with shares traded on the Alternative Investment Market of the London Stock Exchange, was founded in 1985. Ever since that time, it has designed embedded computer boards based primarily on Intel® processor devices, along with hardware and software accessories for use in critical applications.

Manufacturing from its base in Colchester, the business is one of a very small number of companies that design and manufacture embedded computer boards in the UK, and this offers a competitive advantage to the business as Managing Director Jane Annear explained. “We have seen a significant increase in the number of opportunities that either need, or in the case of US customers are prepared to accept, UK manufactured products for security reasons. Alongside this, with around 100 employees, we are big enough to be treated as a key supplier but small enough to adapt quickly to key customer needs. This is very important as many of the applications we supply into need a slightly different mix of I/O, processor type or memory configuration and we are flexible enough to manufacture many variants of a standard product.”

Jane continued with some further details about the range of products and services Concurrent Technologies provides. “The heart of our product range is CPU boards, designed using Intel Atom™, Intel® Core™ and Intel® Xeon® processors. We complement these with associated switches, storage and I/O boards designed to be compliant with industry open architecture standards and provide various application enabling software products. Most product lines are available in both commercial and ruggedized variants, making them suitable for a wide range of applications.

“We start a product design based on devices that are meant for widespread use, then add features such as enhanced security capabilities specific to the markets we’re targeting,” she continued. “For applications in harsh environments, we create custom thermal and mechanical solutions to make sure these products can withstand extreme operating temperatures (-40 to +85°C), high shock and vibration and other hazards like salt fog. We sell a range of these as standard products but also customize variants for specific opportunities. We also need to support the very long life cycles that our customers need, so we often manufacture and support products for ten or more years. Having our own production facility enables us to continue to manufacture products in small batches long after main production has been discontinued.”

Concurrent Technologies’ business model is based around having leading edge products that align with customers needs. Jane shed some light on one of its latest releases as an example: “Our new 3U VPX format TR J4x msd-RCx board is based on one of the latest standards being introduced into some defense applications needing extremely high processing performance,” she explained. “The product is about the size of a postcard, is based on a 12-core Intel® Xeon® D-1559 processor, has 64GB ECC DRAM and 2TB local storage. With 100 per cent processor loading, it operates at a card edge temperature of up to +85°C but with no air flow. It plugs into a backplane for power and to communicate with other processing cards and has a direct 40G Ethernet optical connection. This is typically used as the central controller for sensor based subsystems in a variety of air and ground based situations for applications such as electronic warfare.”

Having referred to some possible functions for the TR J4x/msd-RCx, Jane continued with more details on where Concurrent Technologies tech is utilized. “We supply products to customers worldwide for use in a variety of markets and applications,” she revealed. “Applications for our most recent projects include surveillance, where faster and more in-situ analysis of data is essential, secure communications and ground vehicles, which today include increasing amounts of technology to provide situational awareness, and naval applications such as radar and command and control. We also provide products for use in telecoms and scientific applications.”

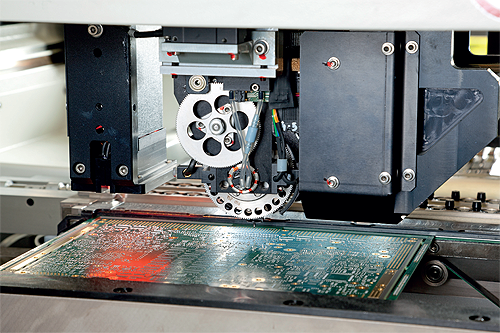

The intricate and high tech nature of the products designed and made by Concurrent Technologies require its manufacturing facilities to be extremely flexible to address the needs of all its clients, some of which have specific requirements. “We operate two ultra-modern surface mount production lines with associated inspection and cleaning equipment that are optimized for relatively low volume, high mix runs,” commented Jane, before shedding more light on the business’ impressive manufacturing capabilities: “The surface mount lines (SMT) print the solder paste onto the bare printed circuit boards before picking and placing the components for soldering. Both lines can deal with 01005 components that are 0.4mm by 0.2mm, so small that they are difficult to see with the naked eye. The Size, Weight and Power (SWaP) characteristics of our finished products are very important and so being able to use ultra-small components gives us the flexibility to miniaturize some aspects of our designs in the future. The SMT lines are designed to operate at a high component placement rate, which lines up with our requirements for speedy build of larger batch sizes but equally important are features like component verifiers to make sure the correct components are loaded as we build lots of different products. We have a few aerospace and defense customers that still require us to build boards using leaded solder which means our production processes have to be flexible as the vast majority of our products use the environmentally-friendlier unleaded solder required by the RoHS legislation.

“Once built, our products undergo a level of optical and X-Ray inspection. Different types of optical machines are used for inspection to the IPC-A-610 Class 3 criteria, making sure the correct components are fitted in the correct orientation and there are no spurious devices. The magnification and sensitivity of the optical inspection matches that of the incredibly small components that we’re fitting, completing a multi-faceted inspection with repeatable accuracy at a rate of almost 3,000 components per minute, to speed inspection times. When we’re setting up new production batches and at appropriate times during the cycle, we carry out X-Ray analysis to ensure that the solder joint quality meets or exceeds the required standards and look for other key manufacturing parameters. We have additional software and hardware capabilities to generate computed tomography sections and 3D views of the internal structures, which helps both from an ongoing inspection perspective but also if we encounter manufacturing or customer issues.

“And, on the odd occasions where we have to rework our products, we have the necessary equipment to do this for the most complex BGA components.”

Jane also highlighted some critical elements of how the process of innovation and new product development is undertaken at Concurrent Technologies. “Our goal is to have products based on the latest technologies available quickly,” she said. “There are two key aspects to this: we align closely with our key silicon suppliers on their upcoming products; and we reach out to our main customers to find out what they need, so for example providing key innovations on data security and cyber security. Marrying these disparate demands together is not easy; there isn’t always one solution for everyone, but we will come up with a concept that works for most of the target opportunities. Our development team includes a wide range of engineering skillsets: mechanical, thermal, electronic, software and systems and they liaise with the operations team to make sure the product is both manufacturable and testable. Supporting the most popular Operating Systems used by our customers is essential to make our products easy to use and install and using our team of engineers we can offer to provide customized versions.”

Client feedback also comes into play when it comes to customer support – Concurrent Technologies prides itself on being available for assistance and advice where required. “Our customers are typically working on very complex applications using our products in combination with third party products and need really good support,” agreed Jane. “When we survey our customer base, the quality and effectiveness of our support is seen as a huge differentiator.”

Another important facet of Concurrent Technologies’ operations is having a direct and local sales presence in the US – this is done through the wholly owned subsidiary Concurrent Technologies Inc. “The parent company, Concurrent Technologies Plc sells directly in the UK and operates through a global network of distributors in most other geographies. Our sales office in China is solely to support our customers in China,” Jane added.

All the Concurrent Technologies facilities are staffed by a team of experienced and skilled individuals, many of whom have worked for the company for more than 20 to 30 years. “Every company is only as good as its employees,” stated Jane, as she expanded further on successful, interactive and collaborative nature of the company’s relationship with its staff. “We have been fortunate to welcome some very talented graduate engineers into the team, which creates a great mix of experience and enthusiasm. We offer the opportunity to see a product from concept to end of life and every stage of product life in between, and every employee is seen as a key part of our team. Communication – keeping all our employees updated with our progress – is always a major objective and this has been made more challenging throughout Covid with many staff working at home when possible. Nevertheless, we have operated as close to normal as we can, in order to meet our commitments to our customers and the team spirit has really shown through.”

Having mentioned the Covid-19 pandemic, which has left no business unscathed, Jane noted that Concurrent Technologies was designated as a key supplier at the start of the first lockdown in 2020, because of the needs of some of its customers. “Our manufacturing and test staff have remained on site whilst all our other staff who can do so have worked remotely. This will continue in order to help with social distancing within the building, but we look forward to having the teams back in the offices when it is safe to do so. There’s nothing quite like face-to-face communication and group discussions to overcome challenges and to share knowledge and experience,” she said. Concurrent Technologies also has the issue of Brexit to deal with going forward through 2021. “Regarding Brexit, we took a strategic decision to source components in advance as the best way to secure important deliveries to our customers,” she divulged. “We are continuing to do this especially as we’ve now seen some component lead times extend significantly.”

As a proud UK manufacturer, Concurrent Technologies is taking all the necessary steps to continue on its path to success. While Covid and Brexit might dominate the current headlines, looking longer-term, Jane and her team have further ambitious plans on the agenda, all based on the solid history Concurrent Technologies has established over the past 36 years. “We expect to maintain our policy of investment to expand our range of advanced technology,” she concluded. “We will focus our efforts on staying in a leading position and satisfying the needs of our customers. We also see opportunities to grow the business organically into new market areas by widening our product ranges and expanding our partnerships with key third parties to provide more complex solutions to our customers.”

Concurrent Technologies

Products/services: Designs and manufactures a range of high performance Intel® processor boards, switches, networking, storage and software products for use in embedded computing solutions

www.gocct.com