Custom Mold & Design’s Trailblazing Innovations in Mold Manufacturing

Custom Mold & Design has remained at the forefront of new and innovative part and process developments over the past 50 years to ensure it provides its clients with a competitive advantage. As the go-to mold manufacturer for the medical device, electronics, defense and industrial markets, Custom Mold & Design prides itself on adopting technology early on while everyone else catches up. “We want to be on the leading edge of technology,” Vice President Lester Jones says. “It’s a challenge exploring uncharted territory, but a positive one.”

Based in Forest Lake, Minn., Custom Mold & Design specializes in mold making, engineering, design and development and assembly. As an outsourcing partner, the company can handle as much or as little of its clients’ projects as needed. Custom Mold & Design combines an experienced design and engineering team with highly advanced technology along with the best-in-class equipment in the industry. At every step, clients can expect careful consultation, attention to detail and customized services that meet their customers’ needs and produce quality results.

In addition, Custom Mold & Design also frequently performs tooling trials on molds by way of its sister company, Teamvantage, which specializes in contract manufacturing and injection molding. Custom Mold & Design is also a corporate sibling of Paradigme Engineering LLC, which the company’s owner acquired in 2017. Paradigme operates a 15,000-square-foot mold design and fabrication facility in Becker, Minn.

Investing in the Future

Custom Mold & Design is constantly investing in new technologies such as conformal cooling and additive manufacturing. Actually, all three companies invest heavily in equipment each year. “We add equipment like it’s going out of style,” Vice President of Sales Tom Caron says. “Our passion for constantly finding new and better equipment sets us apart. We have a specific technology road map; that is, we identify and test different technologies and put steps in place to bring that technology into our organization and use it to the benefit of our customers.”

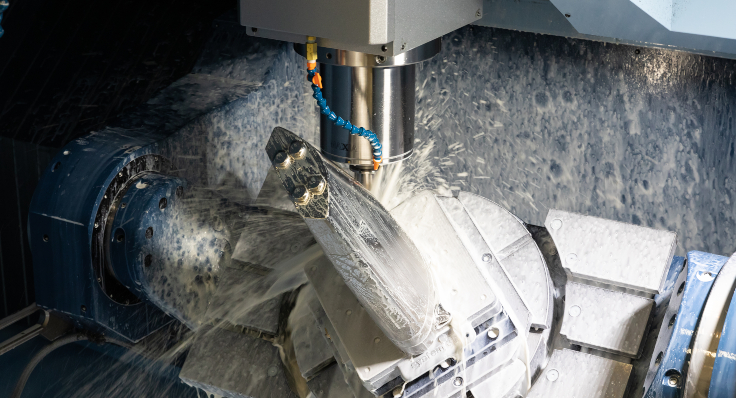

In October 2018, Custom Mold & Design invested in the Matsuura LUMEX Avance-25 Metal Laser Sintering Hybrid Milling Machine, a powder bed metal additive manufacturing platform with subtractive machining capability. The process produces highly accurate parts from metal powders that are melted and sintered using a laser while surfaces are precisely milled at high speeds. Often referred to as a “one machine, one process” system, the Matsuura LUMEX series allows for the production of the most complex and challenging parts through total manufacturing by digital engineering using 3-D data.

“The main use for the LUMEX Avance-25 equipment in our industry is for the creation of conformal cooling inserts instead of using a series of drilled holes,” Jones explains. “This hybrid technology creates hollow areas inside the part, specifically pathways for the coolant to flow along the contour of the part, resulting in even and faster cooling. It reduces cycle time for those who take advantage of this technology.”

3-D cooling channels incorporated into molds on the Matsuura LUMEX Avance-25 increase cooling efficiency and enable high-cycle injection molding with better-than-ever quality and precision, which reduces not only cycle time, but cost as well. “We can see a reduction in cycle times from 10 to 30 percent,” Jones says. “By having the cooling closer to the surface of the mold, we can provide dimensionally stable and accurate parts.”

Conformal cooling for plastic injection molding is an emerging technology and Custom Mold & Design continues to be involved in the research and development of this arena. “We have been involved in the past through building layered components and diffusion bonding processes to put those layers together. This process can work, but often ends up leaking or failing because of the bond,” Jones explains. “Because the market is somewhat new and there are opportunities to learn more and develop new capabilities, people will continue to come up with ways to utilize this technology.”

In terms of manufacturing, Custom Mold & Design says the biggest change involved with conformal cooling is performing more thermal analysis on the front-end to design the cooling channels optimally. “The process is very different from what we are used to, starting with the powder rather than a block of metal, but the end result of injection molding is very similar to everything we have done in the past, in that we are making vast improvement in the injection molding process,” Jones explains.

Game-Changing Technology

The Matsuura LUMEX Avance-25 is a game-changer for Custom Mold & Design. “Previously in the mold building industry, we learned how to use 3-axis CNC machining centers. Then came 5-axis machining and we took that on. With all of these technologies there is a learning curve, but you are essentially doing the same thing with new modifications,” Jones says. “The LUMEX Avance-25 involves working with powder and laser sintering, which is completely different. We have assigned our best people to learn this technology, essentially taking someone who is efficient at 3- and 5-axis machining and throwing them in the deep end of the pool to learn this technology. It certainly requires an investment and patience, but it is rewarding to participate in new and exciting technology and grow professionally. The LUMEX Avance-25 has provided opportunities, as well as challenges for our people.”

Custom Mold & Design began training its team as the equipment hit the floor and although there is still a learning curve, Jones says it is going well. “Each insert we work with has different characteristics that are new, surprising and an opportunity to continue learning,” he adds. “That is part of the reason we are involved – we want to be on the leading edge of technology. There are challenges to being on the forefront, but that’s the fun part. We will be the experts while everyone else is catching up.”

The company prides itself on having a long history working with its equipment suppliers to help optimize both the product and manufacturing processes. Custom Mold & Design has partnered with St. Paul, Minn.-based Matsuura to produce contract manufactured parts for clients who do not want to invest in the equipment but want to take advantage of the technology. “We are helping our clients out by manufacturing the components that they need. By performing the necessary development work, we are expanding our expertise in equipment utilization and process development,” Jones adds. “Combining an accurate, high-speed milling machine and laser sintering is expensive and quite rare. Conformal cooling for mold inserts is the highest and best use for that equipment.”

For example, Custom Mold & Design is machining parts for a client that will go to into space and which require exceptional cooling to function properly. Conformal cooling will allow the part to be more successful. “This is a much more consistent and predictable process and provides a more robust result,” Jones notes. “LUMEX is a strong solution for any industry where cycle time is the driver and where parts create cooling challenges.”

Expanded Portfolio

Custom Mold & Design was founded in 1972 as a design and fabrication house to manufacture complex fast cycling molds and mold components. The company added to its capabilities eight years ago when it created CMD – Precision Manufacturing Group, a division that provides precision machined components and assemblies. “We have very accurate equipment including nine YASDA milling centers, four Makino milling centers, as well as several other milling machines (3, 4, and 5-axis), three Nakamura multi-tasking 12-axis machines, CNC Swiss lathes and wire and sinker EDMs. All of this equipment is located under one roof and this amount of equipment diversification is unusual,” Caron says. “This clearly helps separate us from the competition.”

CMD – Precision Manufacturing Group focuses on lower to medium volume runs in its shared 40,000-square-foot facility, providing services for medical, defense, consumer and industrial applications. “Our goal is to try and have a balance of 50 percent complex tools and 50 percent machine components and assemblies,” Caron says. “We have been making machined components for years. Long ago we came to the conclusion that toolmakers are really good at creating precision components that go into molds, while our machinists are focused on manufacturing components that are more repetitive in nature. In essence, our machined component business is really a factory within a factory.”

The ultimate goal is to offer customers a broader portfolio of services through all three companies. “We are a vertically integrated, one-stop shop,” Caron says. “We can save costs and lead time because we can function as one vertically integrated organization and d not have to buy components from someone else. Because of that, we are able to offer a lower total cost solution for whatever the requirements might be. We have the ability to choose the best-fit opportunities which consist of machined components, tooling design and fabrication, molding and full contract manufacturing.”