Data is the new gold

To help companies extract value from their data, reduce costs, improve efficiency and productivity, Atlas Copco Tools and Industrial Assembly Solutions, has launched a pioneering application, which harnesses artificial intelligence (AI) and machine learning to identify risks in production before they occur.

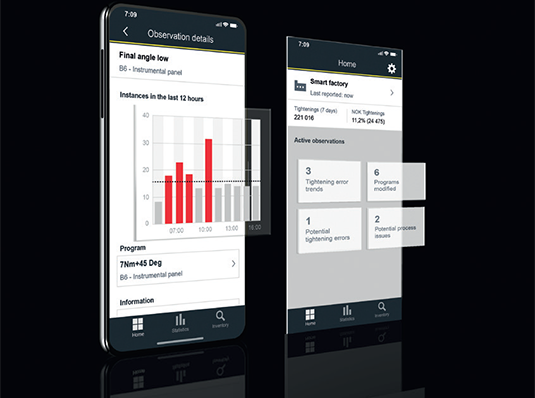

The ALTURE app (ALTernate FutURE) is the latest evolution of Atlas Copco’s Smart Connected Assembly philosophy with the objective of error-proofing the production line, thereby increasing throughput by avoiding product rework or downtime.

Using raw data captured from smart tooling and integrated controllers (only tool data, result data and tightening traces are collected), ALTURE analyses this using AI and an algorithm in the app. Managers are provided with real-time line performance notifications, as well as any ‘Not OK’ (NOK) tightening trends and recommendations for process improvement. Feedback from over 50 of Atlas Copco’s global customers during a 12-month trial confirmed that the smartphone app was the simplest and fastest means of delivering real-time information, enabling personnel on the shop floor to counterstrike any emerging issues.