Dedicated Department of Defense contractor Sechan Electronics supports clients with sophisticated solutions

Focused solely on high reliability electronics for the aerospace and defense industries, Sechan Electronics, Inc. (Sechan) is an end-to-end provider of complex, mission critical electronic solutions. Operating from its facilities in Lititz and Lancaster, Pennsylvania, Sechan manages the full product life cycle, from innovative design and engineering to vertically-integrated manufacturing and long-term sustainment.

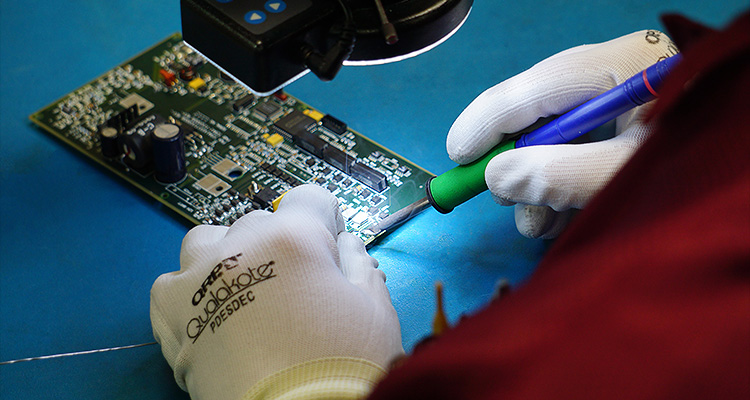

With a proven track record in quality and program execution, Sechan helps to reduce risk and total life cycle costs for its customers. Its comprehensive in-house manufacturing capabilities ensure superior control over quality, schedule and cost. As a high-mix, low-volume solution provider with core expertise in circuit card assembly, wire harness fabrication, box builds, and full system integration, Sechan delivers a wide range of mission-critical solutions, which are deployed on air, land, sea, and space platforms. The company’s partners include BAE Systems, The Boeing Company, Draper Labs, Johnson Controls, L3Harris, Lockheed Martin, Northrop Grumman, Penn State Applied Research Laboratory, Raytheon Technologies, Sandia National Laboratories, and Textron Systems.

Sechan is not a traditional EMS provider; instead, it brings significant expertise in the design and prototyping of advanced electronic and electro-mechanical solutions tailored to meet the demanding specifications of its customers. Sechan’s multidisciplinary team of radio frequency (RF), electrical, mechanical, and software engineers has extensive experience designing, prototyping, and delivering Design for Excellence (DFX) services across tactical communications, mission computers, unmanned system avionics, ground sensor systems, fire control systems, position, navigation, and timing (PNT) systems, and weapons systems.

Sechan follows a defined and closely monitored design process to ensure that each product – and its supporting documentation – meets stakeholder requirements whilst helping its customers achieve their goals. The company adheres to CMMI Level 3 and AS9100 standards, built on ISO 9001 foundations, following a disciplined approach that includes project planning, inventory and configuration management, product integration, verification, and validation. As a product progresses from prototype to Low-Rate Initial Production (LRIP) and ultimately to Full-Rate Production (FRP), the same engineering team remains engaged throughout the entire lifecycle. This continuity ensures that design intent is preserved, optimizations are effectively implemented and production readiness is achieved with minimal risk.

During LRIP and FRP, Sechan excels with an experienced, highly trained workforce certified to J-STD-001, IPC-A-610, and WHMA/IPC-A-620 Class 3 standards for high-reliability electronics. Production is carried out in modern, purpose-built facilities where stringent environmental and electrostatic discharge (ESD) controls are maintained in accordance with ANSI/ESD S20.20 and MIL-STD-1686. All work is meticulously planned and controlled through Sechan’s enterprise resource planning (ERP) system and supported by an extensive suite of advanced manufacturing and test equipment.

Configuration management is rigorously maintained through a comprehensive framework encompassing product documentation, process documentation, and corporate documentation. This system enables full traceability and control of customer-related product drawings, Sechan-generated documents, and associated processes – ensuring configuration integrity throughout the product lifecycle. These operations are governed by an AS9100-certified quality management system, consistently delivering reliable performance and compliance with stringent aerospace and defense standards.

Critical to ensuring product reliability and quality is Sechan’s robust internal testing capability. This encompasses design verification testing, first article testing, qualification testing, environmental stress screening (ESS), EMI testing, and factory acceptance testing – all performed in accordance with industry standards such as MIL-STD-810, MIL-STD-461, and IPC test methods.

As part of Sechan’s Engineering department, program engineers and test technicians perform routine and specialized testing using an extensive array of calibrated semi-automated and automated test equipment. Circuit card assemblies are inspected with AOI/AXI systems and tested using flying probe and in-circuit testing. Wiring harnesses and cables are tested with Cirrus equipment. Subassemblies undergo testing at each stage prior to upper level integration into box builds, where they are typically subjected to ESS and final acceptance testing or ambient acceptance testing. Most subassemblies are tested using program-specific test sets developed to meet customer requirements, with full documentation traceability and customer certification before deployment. Environmental stress screening is conducted in Sechan’s 5,000-square-foot ESS lab, which features multiple temperature chambers, vibration tables, an anechoic chamber, and other specialized test equipment, all operated in compliance with MIL-STD-810 standards.

As part of Sechan’s Engineering department, program engineers and test technicians perform routine and specialized testing using an extensive array of calibrated semi-automated and automated test equipment. Circuit card assemblies are inspected with AOI/AXI systems and tested using flying probe and in-circuit testing. Wiring harnesses and cables are tested with Cirrus equipment. Subassemblies undergo testing at each stage prior to upper level integration into box builds, where they are typically subjected to ESS and final acceptance testing or ambient acceptance testing. Most subassemblies are tested using program-specific test sets developed to meet customer requirements, with full documentation traceability and customer certification before deployment. Environmental stress screening is conducted in Sechan’s 5,000-square-foot ESS lab, which features multiple temperature chambers, vibration tables, an anechoic chamber, and other specialized test equipment, all operated in compliance with MIL-STD-810 standards.

The complex solutions Sechan designs, manufactures, tests, and delivers are typically fielded for decades and require ongoing maintenance, repair, and overhaul. Sechan’s Product Sustainment team – comprising engineers, test technicians, and cross-trained assembly technicians – specializes in troubleshooting equipment and collaborating with customers to develop effective repair or upgrade solutions. These efforts address obsolescence challenges and ensure legacy equipment is brought up to the most current operational specifications.

Sechan operates under the motto “Performance Every Time,” demanding the highest standards from its team while fostering a culture of accountability, excellence, and shared success. Celebrating its 40th anniversary in 2025, Sechan has built a legacy of selfless service, delivering exceptional technical expertise, innovative solutions, and an unwavering commitment to customer success earning numerous supplier excellence awards and formal recognition from its customers over the years.

What truly sets Sechan apart is its ownership model. Since launching its Employee Stock Ownership Program (ESOP) in 1988, Sechan has grown into a 100 percent employee-owned company. Every employee is an owner – fostering a culture of personal accountability, shared responsibility, and a deep commitment to quality, performance, and customer satisfaction. This ownership mindset drives superior outcomes for customers by ensuring responsiveness, reliability, and a long-term focus on excellence across every function of the organization.

In recognition of this exceptional culture, Sechan was named one of the region’s best workplaces by LNP in December 2024. At the time, Sechan’s President and CEO, Mr. Marion Van Fosson, highlighted the critical role of the ESOP in the company’s continued success: “Our culture drives our success, with every employee-owner playing a key role in shaping our future. We take pride in offering best-in-class benefits that support our employee-owners and their families, and our training programs empower individuals to grow and succeed. We remain vigilant in our dedication and commitment to creating a world-class aerospace and defense company where everyone can thrive.”

With decades of proven performance in the aerospace and defense industry, Sechan goes beyond typical EMS providers. From advanced design and prototyping to low-rate and full-rate production, in-house testing, and long-term sustainment, Sechan combines technical excellence with operational agility and superior service. Its vertically integrated model, employee-owned culture, and commitment to quality ensure customers receive responsive, cost-effective, and high-reliability solutions tailored to their most demanding requirements. Whether supporting the US Government directly or serving as a trusted partner to major defense primes, Sechan consistently delivers value through innovation, precision, accountability, and performance every time.