Discover hidden gem CastAlum’s journey as it prepares for ever-increasing demand

With a vision to maximize stakeholder value, CastAlum Ltd strives to be the global supplier of choice for cast aluminum and machined components. Serving as an acclaimed aluminum die casting and machining center in mid Wales, UK, CastAlum takes pride in its capabilities, reliability, and international supply network. Karl Meredith, Managing Director, sheds light on the company’s history.

“CastAlum was formed in 2000 as a subsidiary of Contech, a US operation owned by SPX Corporation,” he begins. “Marking SPX’s first foray into Europe, CastAlum began constructing its first facility that same year. By 2001, we had already started casting, even though the building wasn’t completed. The following year represented our first full year of production, as we focused on servicing one customer from America. In 2009, there was a recession in the automative industry, prompting Contech to file for Chapter 11. In response, CastAlum’s directors in the UK decided to buy the company and become independent, with the support of external investors. This led to several years of significant investments in the business, beginning with the establishment of a machine shop alongside diecasting operations,” he adds.

Karl shares more insights into the series of events and investments propelling CastAlum’s growth in the industry. “In 2018, one of the original major investors bought out the entire company, a major milestone that coincided with my appointment as Managing Director. During this time, we experienced important hurdles primarily due to the uncertainty surrounding Brexit, which made it harder to secure new orders as we were unable to answer questions about changes in taxation and other factors. Since our projects have long lead times, with quoting starting years before the actual program begins, we experienced a decrease in turnover. Thus, from 2018 onwards, we revisited our approach to attracting new clients. Traditionally, we relied on our existing customer base, but due to their concerns about Brexit, we started actively marketing ourselves to a wider audience. As part of this strategy, we invested in on-site additive manufacturing in 2020, as we had previously been handling it off-site. These investments continued in 2021 with the addition of our 14th diecasting cell, and in 2023, we doubled our on-site additive manufacturing capability,” he informs.

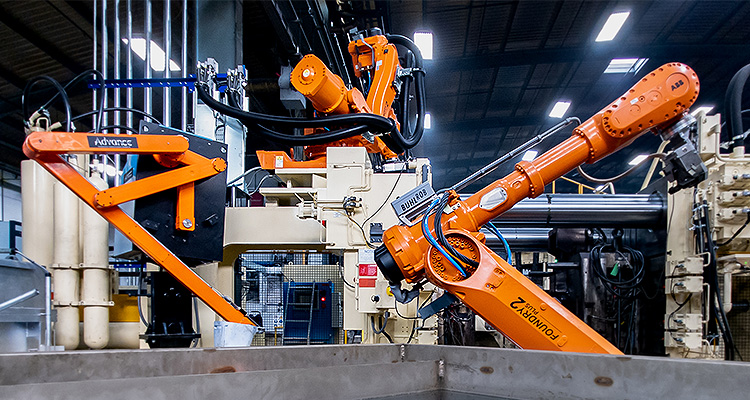

As part of its ongoing journey to enhance operational efficiency and meet growing demand, CastAlum embraces various technologies. “All 14 of our diecast machines are fully automated and equipped with their own furnace, setting us apart from most foundries that rely on bulk melting. I believe this approach is one of the key drivers of the exceptional quality of our products, in combination with using top quality metal which we melt locally, allowing for better control. Prior to 2020, we relied on external sources for additive manufacturing, but we faced challenges in achieving the desired longevity of the tooling inserts we printed. Since our tools are too large to be manufactured on-site, we adopted a different approach. In critical areas of the component, we create a pocket in the die where we can enclose a 3D-printed insert, enabling us to have better control over those crucial parts. By taking on the process ourselves, we addressed the issue of longevity for a couple of years, which required us to modify an off-the-shelf 3D printing machine to achieve the desired results. However, as I mentioned earlier, this issue was successfully solved once we brought the additive manufacturing facility on-site.

“Our ability to produce 3D tooling inserts and immediately transition to volume production makes us quite unique in the European market. This capability empowers us to build an improvement within an impressive two-day period, given that the process includes diagnosing the issue, adapting the cooling system within the die, 3D printing a new insert, and seamlessly integrating it into the die. Five years ago, this level of efficiency was unheard of. Other processes to improve our efficiency include our American diecast machines, which have proven to be very robust and durable. Therefore, whenever we have acquired new machinery, we have remained loyal to the same supplier, whose equipment makes up the totality of our fleet,” Karl elaborates.

“Our ability to produce 3D tooling inserts and immediately transition to volume production makes us quite unique in the European market. This capability empowers us to build an improvement within an impressive two-day period, given that the process includes diagnosing the issue, adapting the cooling system within the die, 3D printing a new insert, and seamlessly integrating it into the die. Five years ago, this level of efficiency was unheard of. Other processes to improve our efficiency include our American diecast machines, which have proven to be very robust and durable. Therefore, whenever we have acquired new machinery, we have remained loyal to the same supplier, whose equipment makes up the totality of our fleet,” Karl elaborates.

While sustainability has become a buzzword across all industries, Karl emphasizes that for CastAlum, “being sustainable was a strategic business decision.” He goes on to explain how the company has implemented eco-friendly practices throughout its operations. “Aluminum and the energy costs involved in melting it make up most of our expenses. Thus, CastAlum has always sought more energy efficient processes, driven not only by sound business practices but also by our dedication to fostering a cleaner environment. Throughout our 24-year journey, we have continually invested in new technologies to achieve our sustainability goals. We consistently upgrade our lighting to better technology whenever it becomes available, even before it becomes necessary. Furthermore, we are constantly evaluating how we can improve our internal processes, for instance by focusing on saving water. Interestingly, CastAlum manufactures aluminum car parts which were previously deemed impossible to produce from aluminum. By doing so, we contribute to creating more lightweight and sustainable vehicles. It is worth noting that most of the aluminum we use is recycled, highlighting our role in championing the circular economy. I believe this is the perfect loop which makes our products infinitely sustainable. This is especially significant considering that over 75 percent of all the aluminum ever produced is still in use today, making it one of the most recycled materials on the planet,” he continues.

Before concluding our conversation, Karl unveils CastAlum’s plans for the remainder of the year. “2024 marks one of our busiest years ever in terms of sales. To keep up with this increased demand, we are set to introduce several new programs, tooling enhancements, and product sampling. Behind the scenes, we are also working hard to support these initiatives. Consequently, we need to hire additional personnel and provide them with extensive training. Lastly, we will also be focused on upskilling our workforce, as we value their expertise and long-term commitment to CastAlum,” he ends.