Discover Knight’s Armament Company and its Leader’s Entrepreneurial Spirit of Innovation Championing the Sector

Knight’s Armament Company (KAC) was founded in the late 1970s by C. Reed Knight, Jr. (Reed) in Vero Beach, Florida, to meet the unique equipment requirements of the special operations and counter-terrorism communities. Providing customers with the ability to rapidly field test these equipment solutions required aggressive in-house research, development, design, prototyping, testing, evaluation and manufacturing. Success in these early government programs established KAC as a premier small arms, accessory, and suppressor designer and manufacturer.

Seeking an expansion in manufacturing capacity due to increased product demand because of the global war on terrorism, KAC acquired a larger facility in Titusville, Florida in 2002. The present campus is located on the site of a former Tomahawk missile production site, spanning over 460 acres and with over 600,000 square feet under its roof.

KAC’s R&D department is the driving force behind its success. Innovative designs are carried from concept to low-rate initial production, while undergoing constant evaluation of their ability to meet design goals and program requirements. New product development incorporates maximum use of non-developmental items (NDI) and commercial-off-the-shelf (COTS) products, where feasible, to minimize development time. The reinvestment of profits enables the company to maintain its strong research, development, test and evaluation department. Through continued testing of manufactured items, KAC constantly improves its products.

Primarily focused on supporting US and allied military forces, KAC’s technology development particularly supports Special Operations Forces (SOF). Product lines vary depending on customer needs as the company provides a full system integration, which drives its small-arms product lines, precision systems, and accessories. KAC can rapidly field equipment solutions which require aggressive in-house research, development, design, prototyping, testing, evaluation and manufacturing. It also provides technical support to various entities to test, develop, and refine technology concepts.

C. Reed Knight, Jr., Owner, Knight’s Armament Company, shares the mission driving his company forward: “We live by the motto ‘nothing is ever good enough’. Through our long, ongoing history with US and international SOF, we consistently receive critical feedback on our products, pushing us to continually test, evaluate and refine our product lines. We are committed to uncovering performance gaps and fixing them. This mentality of constant improvement is not only focused on our existing product lines but emerging technology as well. Advancements in ammunition, simulation software, manufacturing techniques, and evolving customer needs constantly reveal opportunities for product improvement and new product lines. We have been in this industry for over 40 years, relying on manufacturing improvements to continually break new ground in developing products for our customers.

Continual innovation

“We have an honest and transparent relationship with our customers. They feel empowered to give feedback and constructive criticism, to tell us what they don’t like and what needs to be better. Many companies tend to think their product is bulletproof, so to speak. Conversely, we like to believe the customer knows best and approach our relationships from that perspective,” he shares.

With expansion of defense manufacturing on the cards for KAC, Reed believes American industrial success is subject to several key factors. “Innovation revolutionized industry, enabling increased productivity and efficiency. Infrastructure development connects different countries, opening new markets for goods and services. This entrepreneurial spirit and a culture of innovation are essential to American industrial expansion. Visionary entrepreneurs play a pivotal role in establishing and enhancing industries using both innovative ideas, and investment in research and development.

“New access into international markets to satisfy consumer demand is critical to generating healthy economic growth. KAC has reinvested in innovative tools and machines, which enable us to have an aggressive in-house research and development program, to bolster design, prototyping, testing, evaluation and manufacturing. These innovative tools include automation, robotics and additive manufacturing (AM). Our greatest challenge is adapting to the motivation of today’s workforce, which differs from past generations. In our location, the type of manufacturing that necessitates a qualified and specialized labor force is robust, yet the talent pool is limited, causing substantial competition. Maintaining a continued transitional labor force has been challenging. As a manufacturer, we must stay current and relative with workforce requirements.”

For many years, KAC has worked with educators on programs that build a talented local and national workforce, including the establishment and promotion of apprenticeship programs for automation, robotics, and AM, which brings numerous manufacturing companies and government agencies together. “To stay competitive and retake the lead in global industry,” Reed adds, “the American public and American industrial base need to invest in this qualified workforce.”

Knowing the company needs to stay relevant and current with manufacturing processes, KAC dipped its toes into AM with one machine: a Renishaw AM250 single laser machine, later adding a Renishaw AM500Q. “I was concerned the cost of the AM method would not be practical and anticipated high volume would be needed to justify the investment,” Reed explains. “By introducing AM to KAC’s manufacturing method, I quickly found that it took a complete change in the way of thinking from design to manufacturing to optimize the advantages of AM. This is an entire manufacturing process. AM itself is a small piece of the processes needed to make a part. As such, we had to establish a whole new team to meet the challenges of AM, to explore different processes to find solutions.”

Emerging technology

AM has given KAC the advantage of building product that could never be made in a conventional method. In harnessing the advantages of AM, KAC was able to acquire a new patent, demonstrating the value of adapting to this emerging technology. Additionally, KAC was instrumental in establishing the first approved AM apprenticeship program in the State of Florida.

“At KAC,” Reed continues, “our automation and robotics (A&R) department has been deploying a multitude of automated systems throughout our facility and manufacturing processes. My highest directive to this group has always been to provide lean robotics to reduce production costs and increase productivity through ‘light’s out operation’. The automation team also supports the manufacturing operations. In ‘light’s out operation’, internally known as ‘Knight Shift Automation’, we focus on designing robotic systems capable of functioning in uninterrupted mode for a duration of approximately 14-to-16 hours overnight while requiring virtually no supervision or operator intervention.

“To achieve our goals, we continuously and relentlessly seek opportunities to assist our partners in production, scheduling and quality departments, facilitating significant process improvements, ranging from individual workstations to fully automated machine tending robotics cells. One major constraint is our high mix of part types, sizes and materials making all designs extremely challenging,” he elaborates.

Automated systems

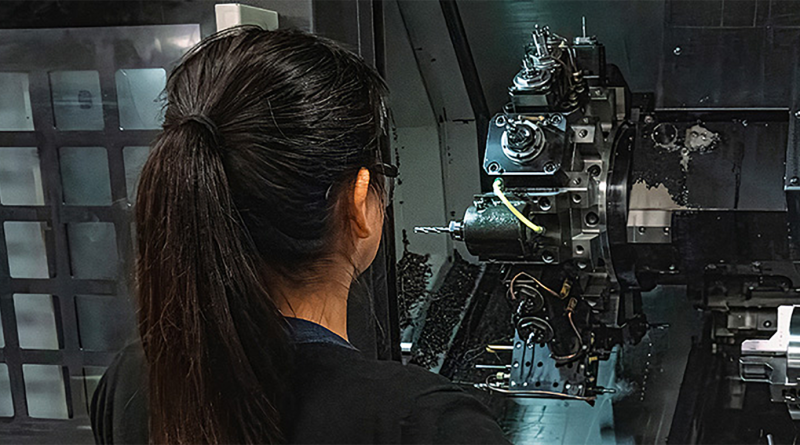

KAC’s first significant A&R success story was a concept initiated many years ago by Reed and his team to simultaneously load and unload parts into a CNC machine in record time. The system can carry up to 60 parts in a single batch, and the chip-to-chip cycle time averages between ten and 15 seconds. With this system, considering a CNC operation of 15 mins, the total runtime for a fully loaded system is around 15 hours of unattended operation, which is ideal for the company’s targeted mode of operation and is greatly impacting the production throughput of many of its processes.

“For the past few years, we have been fulfilling our production requirements by developing highly efficient and integrated tending machines, including Fanuc robots and other ancillary sub-systems, creating a well-oiled multi-stage structure of automated systems capable of running several combined steps in our processes,” he continues.

“Gains in greater quality and productivity are realized by augmenting the duration of production with unattended extended hours at reduced cost and increased production volumes. Future projects are to reduce and combine manufacturing steps, implementing automation with limited tooling for higher and faster adaptability and increase continuous running hours on the assets.”

Alongside technological innovation to enhance production, KAC values its workforce and their respective valuable contribution. CareerSource Florida provides workforce training grants for integrated talent support solutions to help businesses like KAC find, develop, and keep talented employees. Reed elaborates: “The CareerSource Florida team provides the expertise, funding and resources that we value. They help us source suitable and relevant talent to help fill the critical positions we have.

“We have three apprenticeship model programs to attract and cultivate talent within our specific industry as well as the manufacturing industry in general. KAC also uses an employee referral program; a recruiting strategy that encourages our employees through rewards to refer qualified candidates for our company. Likewise, for many years, we have fostered relationships with local high schools and colleges, revealing and promoting the significant benefits of working in the manufacturing industry. Developing young people’s interest in the manufacturing field is the most important step in their building a career in our industry, and KAC is proud to actively play a role in encouraging this.

“Alongside my focus on workforce improvement, and especially with numerous concerning matters across the globe, there needs to be a concerted effort to streamline the supply process as well. America needs to have a strong industrial base, and it cannot do it without passionate entrepreneurs, a trained workforce and new innovative manufacturing methods. We need the American people pulling together to partner with educators, industry and politicians to build a workforce that prioritizes strength to secure our nation’s future; KAC proudly champions this cause.

“Looking further afield, if I had one wish, it would be that the world was at peace and no longer needed a company like KAC,” Reed concludes. “That said, I probably won’t be able to recognize the company in the next five years if we progress as much as we have in the last five. Finally, if America does not bring innovative manufacturing back to the US, like we did in WWII, we will find ourselves falling behind other inspired countries.”