Discover Philtronics’ inspiring story, as it revolutionizes turnkey manufacturing and invests in talent

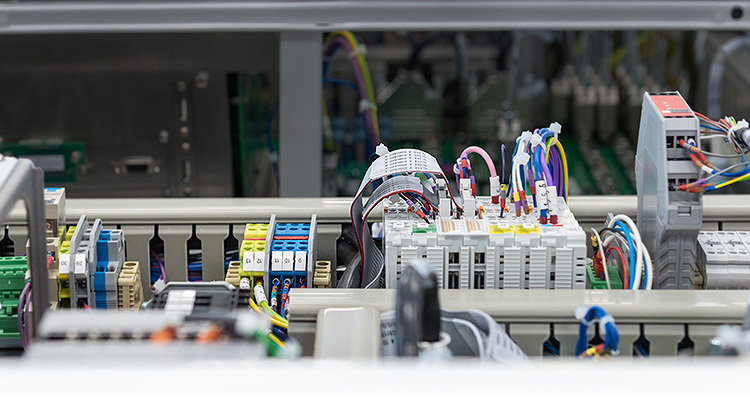

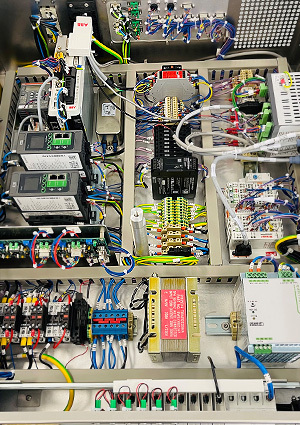

Over the past 20 years, Philtronics Ltd has emerged as a key supplier of full turnkey products in the global semiconductor and wafer fabrication sectors. As a contract electronic manufacturer (CEM), Philtronics offers outsourced electronic manufacturing services (EMS) to customers who require fast turnaround with exceptional product reliability. With its unmatched expertise in precision and box build manufacturing, the company has grown and developed its skill set and evolved into a one-stop shop for contract electronic assembly. From early design concepts and rapid prototyping to design for manufacture and assembly and supply chain optimization, Philtronics caters to the diverse needs of its valued customer base. Additionally, the company handles product standardization, design approval processes, build, testing, and logistics. These services go a long way to simplifying consumers’ supply chains, reducing lead times, accelerating time-to-market, and ultimately helping customers win more business opportunities.

Simon Pritchard, CEO, recounts the journey that led to the creation of Philtronics. “Incorporated in 2003, Philtronics is a Welsh company with headquarters based in the beautiful town of Hirwaun. A vibrant hub for manufacturing and associated supply chains, Hirwaun not only attracts individuals seeking employment, but the town’s highly motivated workforce makes it an appealing destination for employers across various industries. Having grown up in this town, I have witnessed firsthand the influx of people drawn to Hirwaun by its thriving job market. I began my career as a buyer and found myself working closely with large OEMs (Original Equipment Manufacturers). Over time, I took on the role of managing and overseeing the activities of the suppliers, ensuring their compliance and alignment with the objectives of the OEMs. As my career progressed, I became a senior buyer, purchasing manager, and project manager. Continuing on my career path, I decided to build my own business.

Simon Pritchard, CEO, recounts the journey that led to the creation of Philtronics. “Incorporated in 2003, Philtronics is a Welsh company with headquarters based in the beautiful town of Hirwaun. A vibrant hub for manufacturing and associated supply chains, Hirwaun not only attracts individuals seeking employment, but the town’s highly motivated workforce makes it an appealing destination for employers across various industries. Having grown up in this town, I have witnessed firsthand the influx of people drawn to Hirwaun by its thriving job market. I began my career as a buyer and found myself working closely with large OEMs (Original Equipment Manufacturers). Over time, I took on the role of managing and overseeing the activities of the suppliers, ensuring their compliance and alignment with the objectives of the OEMs. As my career progressed, I became a senior buyer, purchasing manager, and project manager. Continuing on my career path, I decided to build my own business.

Value-added services

“Driven by my understanding of the industry’s needs, I knew that relying solely on total acquisition cost and continuous outsourcing to the cheapest available country would prove to be a flawed strategy. Instead, I formulated the business around a full turnkey proposition from the outset, as I foresaw significant benefits in providing value-added services throughout the business process. Additionally, having access to the skilled workforce in Hirwaun played a crucial role in bringing Philtronics to life. From its inception, Philtronics set itself apart by offering full turnkey services. Typically, it takes time to gain customer confidence and establish a company capable of building complete products. However, we have been fortunate enough to partner with a major player in the semiconductor industry over the past 20 years. This partnership has aided our strategic journey and provided valuable insights that we’ve been able to apply to other sectors such as automotive and medical,” he elaborates.

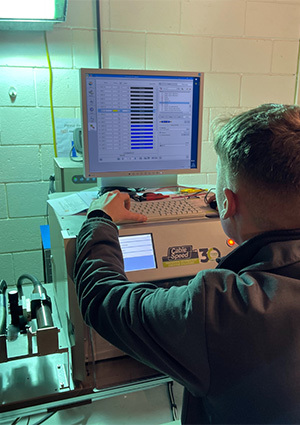

To address the labor shortage crisis faced by the manufacturing industry, Philtronics has launched a new academy to support local talent. “Philtronics Academy aims to address the labor shortage issue at ground level. While there is a shortage of skilled professionals, particularly engineers, too significant a focus is often placed on academia as the solution. Although academia does play a role in addressing the issue, it is not the sole solution. I believe that our business is like an ecosystem and that if there is a skills shortage in any area, we should strive to develop our own talent. By providing our workforce with the necessary skills, we can leverage our existing staff to fill the positions affected by the labor shortage. OEMs and the industry collectively are investing significant resources to address the skills shortage through academia. However, in this specific area, there is a large proportion of individuals who left school at around 16-to-18 years of age. Many of them have negative perceptions of their previous educational experiences and feel that factory jobs offer limited opportunities. To change their perception and show them alternative pathways, we need to emphasize that internal opportunities exist within Philtronics. These pathways are not dependent on returning to academia, as most of these newcomers are not inclined to go back to a classroom setting or attend boot camps to acquire the skills they need for their current roles in the factory.

Investing in local talent

“Therefore, the academy is an internal learning resource that operates through two primary routes. The first route focuses on upskilling our existing workforce through leadership development, mentoring, management training, and tailored activities. The key objective is to create a safe space within our factory where every individual feels comfortable and empowered. The academy provides an environment where they can take risks and learn from failures fast. In other words, within this non-academic institution, distinct from their previous school experiences, individuals can experiment, make mistakes, and quickly learn from them. So far, this formula has proven successful. The second avenue we have pursued is collaborating with local academia to develop customized training workshops that cater specifically to the unique needs of Philtronics. We have designed the curriculum for these workshops to be completed within a ten-week timeframe. Our goal is to employ the majority of participants immediately after the boot camp, as they will have gained a comprehensive understanding of our work environment, job responsibilities, and available career pathways even before they start their first day,” ends Simon.

Through its ongoing investments in developing local talent, Philtronics is well-positioned to continue delivering exceptional value to customers.