Domestic manufacturing is the key to success for AHF Products as it continues to dominate the U.S. flooring market

When it comes to transformational potential, there are few products that can make a greater impact on a project than the right flooring. With benefits stretching from design innovation and warmth to safety and aesthetics, the right floor can significantly change a space, and if there is one manufacturer that understands the pivotal role of flooring, it is AHF Products (AHF).

Describing itself as a ‘new old company’, AHF is actually only five years old, and was created in 2019 when the former Armstrong Flooring, Inc. sold its wood division to a private equity firm. Today, its portfolio includes brands that have stood the test of time, some over a century, featuring hugely respected names such as Armstrong Flooring™ and Bruce®, alongside Hartco®, Robbins®, LM Flooring®, Tmbr.™, Parterre®, AHF Contract®, Autograph™ Flooring, Hearthwood®, Raintree®, Homerwood®, Capella®, Essential Living™, and Crossville® Tile. Through this powerful broad offering of hardwood, resilient, laminate, and tile flooring products, AHF can meet and exceed customers’ needs across commercial, residential, small, large, or even enormous projects!

To learn more about the fascinating evolution of AHF, we sat down with Brian Carson, President & CEO, Jake Loftis, COO, and Jennifer Zimmerman, CCO, who reflect on the company’s journey to its current market-leading position.

To learn more about the fascinating evolution of AHF, we sat down with Brian Carson, President & CEO, Jake Loftis, COO, and Jennifer Zimmerman, CCO, who reflect on the company’s journey to its current market-leading position.

“I’ve been in the flooring industry for almost 35 years, and I actually started as an engineer in one of the factories now operated by AHF, so it has really been full circle,” begins Brian. “The Armstrong Flooring brand is around 150 years old, as is Bruce and Robbins in wood flooring, hence the tagline ‘America was built on our floors’. It has been a fruitful journey since; we’ve completed six acquisitions in five years, the fourth of which saw us acquire Armstrong Flooring’s key assets along with three plants, and most recently Crossville Tile.

“Our first objective was to get our wood flooring business, led by Bruce, running healthily, before venturing into providing multiple hard surface options. We acquired two vinyl flooring businesses and three hardwood businesses, for instance, and around six months ago, we acquired Crossville, a porcelain ceramic business which moved us into the fast-growing tile sector, with a line of porcelain, ceramic, stone and accessories for both the residential and commercial markets. Today, we are a comprehensive, vertically integrated supplier with 15 domestically made brands in our portfolio, participating in around 60 percent of the U.S. flooring market, compared to just ten percent when we first started.”

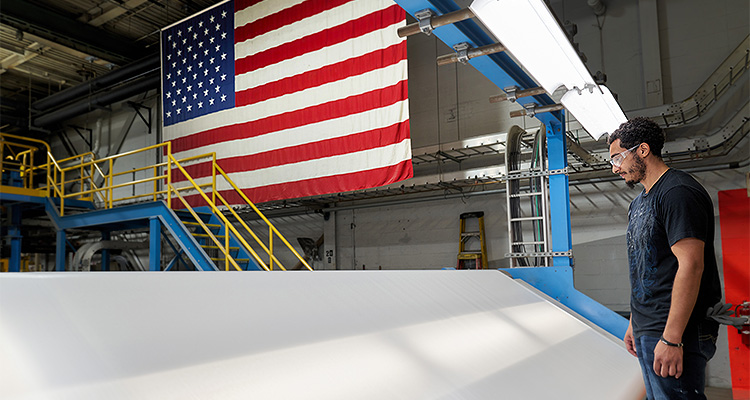

One of AHF’s greatest assets is its 12 manufacturing plants across the U.S., plus a complementary site in Cambodia. “Our domestic capacity is one of our competitive advantages,” Jennifer states. “It enhances our relationships with customers as they don’t have to carry inventory or wait on typical Asian lead times of up to four months. We can manufacture products much quicker and having a ‘Made in the USA’ product really resonates with consumers.

“With the broadest product portfolio of any hard surface flooring manufacturer, we’re also vertically integrated, and offer a more reliable supply chain. We even recently converted one of our plants to provide an in-house sampling capability, which is more cost-effective, gets the samples out to customers quicker, and reduces our reliance on a third party.”

Jake adds: “We’ve purchased two sawmills to vertically integrate some of our raw materials, enabling a consistent flow of product to our solid hardwood plant in Beverly, West Virginia, and thereby, protecting supply to our customers. The sawmills currently account for around 20-to-25 percent of our overall lumber consumption, which is a great balance and means we’re not over indexed.”

Having grown significantly in just five years, we’re keen to explore how AHF seamlessly blends history with innovation and contemporary trends. “We’re able to take the heritage and legacy of brands like Bruce and Armstrong Flooring and reposition them in the market by integrating them within our structure and cost model,” says Jennifer. “The customer base is reacting very well. With Armstrong Flooring specifically, there was previously a lot of doubt and uncertainty as to what would happen to the business, so people are thrilled to see the brand still thriving in the industry.”

Brian agrees: “We recognize that while flooring is an aesthetic purchase, it’s also an emotional one. It is the canvas on which you paint your home or business, but we’re also using heritage as a platform for investment and innovation. As technologies change, some of our competitors have shifted towards a sourcing model, but we’ve invested in our domestic manufacturing capabilities instead. It’s our job to ensure that the brands appeal to the preferences and trends of today’s audience while maintaining the features and benefits that consumers associate with these brands.

“We’re doing so by producing flooring for today’s market, but with an eye on the necessary investments to be made to ensure we cater to tomorrow’s market. We’re investing more than $40 million in our U.S. plants, for instance, to add new capabilities, designs, features, and benefits to the facilities, as well as additional capacity to make the products of tomorrow. At AHF, we embrace a nimble, forward-thinking approach to flooring solutions that drives value for our partners.”

Jake continues the topic of investment, elaborating on how the company has allocated funds to transform several of its sites across the U.S. “I’m happy to report that at our Beverly, West Virginia, site, which is the largest solid wood flooring facility in North America, we’re months ahead of schedule on installing four new fully automated scan chop lines,” he says. “Along with two recently installed panel sanding lines, this equipment is centered around quality, throughput, elimination of waste, providing higher yields, and driving overall productivity. The many benefits of which are passed on to our customers in terms of added value.

“We’ve also spent millions of dollars on capital at our site in Kankakee, Illinois, where we make vinyl composition tiles, to expand output, increase reliability, and introduce new-to-market products. While we’re acquiring and inducting businesses into the AHF family, we’re also focusing on continuous improvement, providing each plant or brand with the tools and mindset to match the current market.”

introduce new-to-market products. While we’re acquiring and inducting businesses into the AHF family, we’re also focusing on continuous improvement, providing each plant or brand with the tools and mindset to match the current market.”

At AHF, business is personal. With a deep-rooted belief in the power of teamwork, transparency, and trust, the company considers its staff, customers, and suppliers as true partners. AHF pledges to deliver reliable, consistent, and best-in-class products, services and support and to be fair, honest, and dependable in all professional dealings. From home builders and commercial contractors to distribution and consumers, recent investments in the U.S. operations will continue to deliver added value and superior customer service.

“We’re not afraid to scrutinize ourselves and find ways to disrupt our own traditions,” Jake states. “We’ve grown tremendously from where we started and we now have a lot of different paths to market, so we must constantly evolve. We’ve been on a digital transformation journey over the last year, working relentlessly to make information available at a moment’s notice. We’ve harvested information into data lakes, which can be pulled through our business intelligence model, enabling us to react faster to market changes with data-driven decisions.”

Complementing U.S. operations in Cambodia When AHF was established in 2019, the Chinese wood products market had come under scrutiny from the U.S. Government, subsequently leading to section 301 tariffs applied to all Chinese engineered hardwood. Identifying a strategic opportunity, AHF invested in a factory in Asia (but not in China), to intercept business leaving China. “We purchased a company called LM Flooring with a large plant in China and a small plant in Cambodia. We shut the plant in China down and moved the equipment and staff to Cambodia, which has made us the largest U.S. employer in that country and the only American flooring company to have a plant in Cambodia,” Brian explains. “We employ more than 800 people at the site. This is our most versatile facility, with the ability to ship to the U.S., Australia, New Zealand, and Europe, which we wouldn’t otherwise be able to do.” Jake elaborates: “The factory in Cambodia is complementary to AHF’s product offering, producing unique visuals and features that allow U.S. manufacturing to focus on higher-end or specialty products. This nimble and forward-thinking approach to investment drives value for our partners. We’ve tripled the size of the plant since we’ve owned it and we operate with the same regulations as our U.S. sites, including our worldclass safety standards, which are four times better than the industry average. “We’ve installed equipment to automate packaging, stacking, and to feed production lines, as well as new technology to produce herringbone and chevron flooring. We have recently installed additional emissions controls to our boiler system, and we’re continuously looking at options to automate and vertically integrate the factory.”

Brian goes on to share an interesting consideration when it comes to automation. “It’s particularly complex to automate the manufacturing processes for hardwood engineered flooring,” he explains. “Take synthetic flooring, for instance, which requires printing, the quality control aspect can be somewhat easily automated by a computer. In contrast, wood flooring is a natural product sold at random lengths in the U.S. and therefore has character like knots or different grain, making it much more difficult for an automated system to decipher what a good piece of wood looks like. While we acknowledge automation is crucial to maintaining our manufacturing footprint in the U.S., we must implement it in a careful way to ensure select products retain a natural aesthetic and have an emotional attachment.”

Jennifer adds: “We’ve also undergone a total transformation of our plant in Somerset, Kentucky, to meet current market demands. The site previously manufactured a product that was declining in volume, so we installed new equipment and technologies to upgrade our capabilities and bring a brand-new product to the market – Densified WoodTM. This revolutionary technology – 100 percent natural hardwood floors not only withstand gouges and stains but are also waterproof – is exclusive to AHF and is intended to withstand wear and tear in high traffic areas.”

Dedicated to driving heritage forward, it’s clear that AHF will continue to grow and succeed in the future. “With freight rates currently on the rise again and volatility in the ocean freight market, our domestic manufacturing footprint gives us a distinct advantage,” Jennifer suggests. “We’re also optimistic about business in the U.S., as the domestic market is predicted to cycle back up in the next two-to-three years.”

Brian concludes: “We will continue to be rooted in manufacturing to grow alongside our customers, as well as adding more product categories and channels that deliver a strong return on investment. We’re constantly finding ways to simplify processes for our customers and make it easy to do business with AHF. Looking in the long term, our ultimate goal is to continue exceeding customer expectations and leave something enduring for the next generation of leadership.”