Elephantech’s Game Changer in Flexible PCB Manufacturing

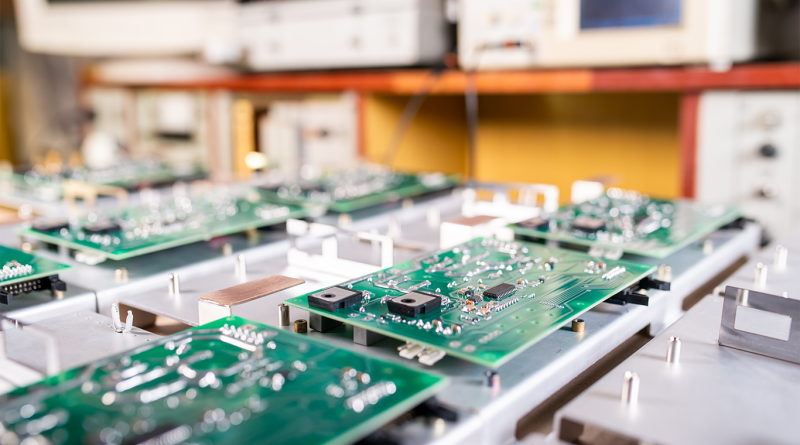

Elephantech Inc., a pioneering startup in the electronics manufacturing sector, has revolutionized the production of printed circuit boards (PCBs) with its innovative metal inkjet printing technology. Founded with a vision of making the world more sustainable through novel manufacturing techniques, Elephantech has set a new benchmark by becoming the first company to mass-produce flexible PCBs using this groundbreaking method. Flexible PCBs are integral to modern electronics, providing essential functions in devices ranging from smartphones to medical equipment. By leveraging metal inkjet printing, Elephantech not only enhances production efficiency but also significantly reduces environmental impact.

The core of Elephantech’s innovation lies in its proprietary metal inkjet printing process. Traditional PCB manufacturing typically involves a subtractive process where copper is etched away to form circuits, generating considerable waste and consuming substantial energy. In contrast, Elephantech’s Pure Additive™ method directly prints metal nanoparticles onto a substrate, followed by an electroless copper plating process. This additive approach eliminates the need for harmful chemicals and significantly reduces water usage and waste production..

Elephantech’s P-Flex® PCBs are a prime example of the advantages of this technology. These flexible PCBs use 70% less copper, emit 75% less CO2, and require 95% less water compared to conventional methods. This innovative approach not only meets the growing demand for high-performance electronic components but also aligns with global sustainability goals

PCBs Are Revolutionizing the Electronics Industry

Elephantech’s technology represents a significant leap forward in eco-friendly electronics manufacturing. The P-Flex® PCBs offer substantial environmental benefits, including reduced carbon emissions and conservation of natural resources. For example, by using metal inkjet printing, Elephantech cuts copper usage by 70%, which helps mitigate the environmental impact associated with copper mining and refining. Furthermore, the significant reduction in water consumption (by 95%) and carbon emissions (by 75%) underscores the environmental superiority of this method over traditional processes.

Several case studies highlight the practical applications and benefits of Elephantech’s PCBs. Major electronics manufacturers have adopted P-Flex® PCBs in their products, enhancing their sustainability profiles and meeting increasingly stringent environmental regulations. This adoption reflects the industry’s recognition of the value and potential of Elephantech’s technology in driving sustainable practices.

Elephantech’s journey has been marked by impressive growth and substantial financial backing. The company has raised over $70 million in funding, enabling it to expand its production capabilities and explore new applications for its technology, including semiconductor post-processes and display technologies. The market has responded positively to Elephantech’s offerings, with increasing demand from global electronics manufacturers looking to integrate sustainable practices into their production lines.

Looking ahead, Elephantech faces the challenge of scaling up its production while maintaining its commitment to sustainability. The company is heavily invested in research and development to refine its technology and develop new applications. With the continued emphasis on sustainability in the electronics industry, Elephantech is poised to play a pivotal role in shaping the future of PCB manufacturing.

Addressing Challenges and Pioneering Future Innovations in PCB Manufacturing

Despite its remarkable advancements, Elephantech faces several challenges as it continues to innovate and expand its operations. One of the primary hurdles is scaling up the production of P-Flex® PCBs to meet the increasing global demand while maintaining the high standards of sustainability and quality. The transition from pilot production to full-scale manufacturing involves complex logistics and significant capital investment. Moreover, Elephantech must continually refine its metal inkjet printing process to enhance efficiency and reduce costs further.

Another challenge lies in the research and development (R&D) front. As a pioneer in metal inkjet printing technology, Elephantech is committed to staying ahead of the curve by continually improving its processes and exploring new applications for its technology. This includes potential uses in semiconductor post-processes and display technologies, which could open up new markets and opportunities for growth.

To address these challenges, Elephantech is investing heavily in R&D and seeking strategic partnerships to bolster its technological capabilities and market reach. The company’s collaborative approach involves working closely with industry leaders and research institutions to push the boundaries of what is possible with metal inkjet printing. Additionally, Elephantech is expanding its production facilities and exploring opportunities in various regions to better serve its global clientele.

Looking forward, Elephantech’s prospects are promising. The growing emphasis on sustainability in the electronics industry aligns perfectly with Elephantech’s mission and technological strengths. As environmental regulations become more stringent and consumers demand greener products, the demand for eco-friendly manufacturing solutions like those offered by Elephantech is expected to rise. The company’s continued focus on innovation, quality, and sustainability positions it well to lead the charge in transforming PCB manufacturing and beyond.

Sources: