Four best practices to go beyond digital twins. By Kyle Pearce

In recent years, digital twins have risen to the status of core technology for industrial companies. McKinsey has predicted that investments in digital twins will exceed $48 billion by 2026.

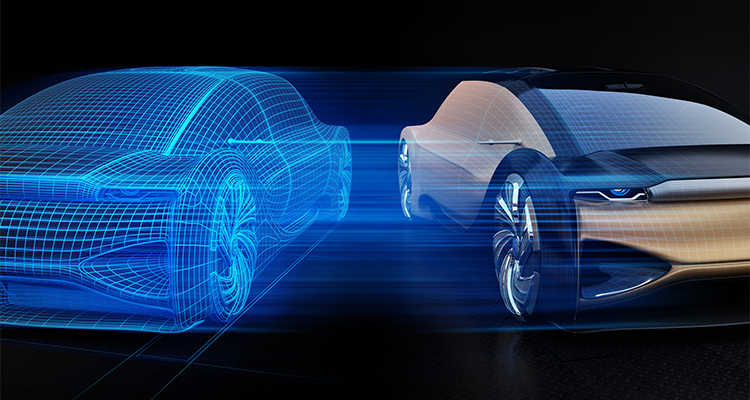

Organizations can leverage digital twins of products, processes, or facilities as the gateway to a smart digital reality. Journeying to a smart digital reality has many steps and so it’s crucial to understand the role that digital twins play in that process.

Smart digital reality

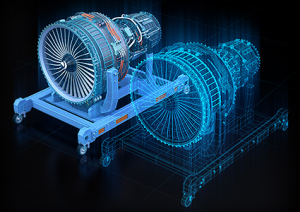

Well implemented, a digital twin can help deliver value across the complete lifecycle of a facility and its assets and increase efficiency, productivity, and safety, among others. Across companies, the definition and scope of a digital twin can vary significantly.

For some people and organizations, that’s just a 3D model. For others, it can include laser scans or some fancy electronic document management system. Reducing digital twins to a single tool or data source greatly limits the benefits.

That is why smart digital reality aims to take the representation far beyond a static, single source of truth. It focuses on creating a unified, real-time view of the physical and digital realities and infusing it with intelligence to automate processes and analytics. It leverages data collected from sources across the complete lifecycle and gathers it in one place to provide organizations with a complete line of sight to their assets.

…and what gets in the way

To create this smart digital reality, companies need to overcome several potential obstacles. Firstly, inefficient or incomplete captures of data are often in disparate, unintelligent document formats, with poor handovers of information between project phases. The lack of reliable 3D models or laser scans means that there is no basis for a digital twin or digital reality. In the operations phase, the complexity of systems and proprietary equipment. Lastly, maintenance and engineering procedures are often done manually, making it difficult to leverage that information in a digital reality environment.

To address these obstacles and unlock the full benefits of smart digital reality, organizations can look to implement the following best practices.

Best practice #1: Go beyond basic 3D models to incorporate context and multiple data sources

During the project phase, companies often focus on creating a 3D rendering of their asset. The most important thing is to ensure quick access to live information in a single place and provide the context needed for decision-making. Therefore, digital twins will certainly contain information from 3D models or laser scans, but they must go beyond that and connect to external systems.

In addition, during the project phase, scans or point clouds of the facilities need to be enriched with geotags to mark relevant areas or pipes. This information can later be used to link to the relevant documentation and create effective contextual navigation.

#2: Maximizing a digital twin’s value across the full lifecycle

Another best practice during the project phase is to invest in organizing and ‘smartifying’ documents to remove the information that they contain and recreate it with the relevant metadata – such an investment can pay massive dividends later on.

In particular, implementing a structured and automated facility handover process can save a lot of time and frustration during the operations and maintenance phases. Some studies say that companies can spend up to two years organizing documentation after an insufficient handover.

#3: Aim for a ‘single pane of glass’

Putting those mechanisms in place during the project, design, and execution phases helps to ensure that the right information will be available to engineers or maintenance technicians in the operations phase. It also prevents future struggles with outdated or unreliable information.

This data then needs to be connected to operational data, such as information on shift operations, control system performance, or operating procedures. Fortunately, much of this data is usually already being collected, even if it’s manual. The key is to digitize, connect, and integrate it into a digital backbone that will underpin the smart digital reality.

#4: The role of stakeholder management

Finally, the crucial importance of stakeholder management in creating and maintaining a smart digital reality should not be overlooked. It is not just about figuring out how to collect information, but also about involving major stakeholders and users of that information. The single greatest recipe for failure is a lack of commitment from key stakeholders.

Developing and outlining the benefits these stakeholders will obtain is key. For example, on the EPC side, construction planners will have a single place to check to ensure that projects are running on time or find out where they need to act. For engineering departments, it can also help retain momentum during project phases and ensure that the right information and history are kept in one place. In operating facilities, beneficiaries include plant management, engineering, and operations teams. Management staff will use the information collected to support decision-making and obtain key performance indicators (KPIs) at single or multiple sites.

Similarly, it is essential to involve and support the people working in areas where data will be collected. Operations supervisors, for example, may have to use new software, to move away from paper-based processes. And, as with any digitization effort, the move to smart digital reality depends just as much on what happens on the shop floor as on what is decided in the boardroom. ■

For a list of the sources used in this article, please contact the editor.

Kyle Pearce

www.hexagon.com

Kyle Pearce is Senior Industry Consultant, Asset Lifecycle Intelligence Division, at Hexagon, the global leader in digital reality solutions, combining sensor, software, and autonomous technologies. Hexagon’s Asset Lifecycle Intelligence division helps clients design, construct, and operate more profitable, safe, and sustainable industrial facilities. It empowers customers to unlock data, accelerate industrial project modernization and digital maturity, increase productivity, and move the sustainability needle.