From additive manufacturing capabilities to hydrogen seals, John Crane’s commitment to innovation makes waves in the engineered products sector

An integral part of the Smiths Group, which is listed on the FTSE 100 on the London Stock Exchange, John Crane is a provider of engineered products and services. Specializing in mission-critical mechanical seals, couplings, seal support systems, filtration systems, and digital diagnostics technologies, the subsidiary pioneers solutions for the energy and process markets. John Crane’s services enable efficient and sustainable operations, in line with its belief that prioritizing environmental responsibility and sustainability is vital. This enduring dedication drives the company to continually develop and implement technologies that are essential for powering a more sustainable future. Mike Eason, Chief Technology Officer, shares exclusive insights into John Crane’s history and operations.

“Founded in 1917 in Chicago, John Crane boasts over 100 years of innovation in manufacturing, product design, and service. Our vision is to protect the planet’s resources by providing engineering solutions specifically for the energy and process industries of the future, with a focus on energy transition and production,” he begins.

“Founded in 1917 in Chicago, John Crane boasts over 100 years of innovation in manufacturing, product design, and service. Our vision is to protect the planet’s resources by providing engineering solutions specifically for the energy and process industries of the future, with a focus on energy transition and production,” he begins.

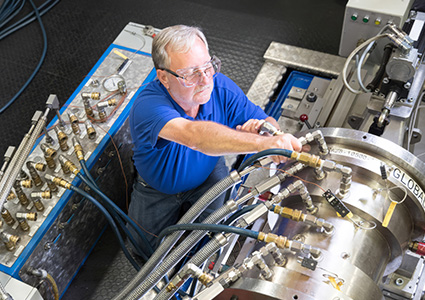

“Managing and controlling the flow of fluids is a central part of our activities, alongside manufacturing mission-critical sealings (including mechanical seals) and support systems (namely couplings and filtration technologies), which are used in conjunction with our seals. Our purpose is to make our customers’ operations more efficient and sustainable while helping industries meet the needs of energy and processes for the future. As a mechanical engineering business, we differentiate ourselves through our design, materials and manufacturing technology, but also crucially through our exceptional customer service.

“We have installed more mechanical seals than any other company in the world, which wouldn’t have been possible without our incredible team of over 6000 employees operating across 200 sites globally. In the fiscal year 2023, we reached a significant milestone, as our business revenue exceeded £1 billion for the very first time. This accomplishment positioned us as a reasonably large business,” he adds.

Exciting developments

Like other businesses of its size, John Crane’s operations rely heavily on cutting-edge machinery and equipment. Mike provides a detailed account of the technologies the company has invested in to enhance its processes. “We have embraced additive manufacturing capabilities with the implementation of a development and production additive manufacturing cell in our Slough plant and production cells in our Czech, German and US plants which are used to produce subcomponents in-house. It has brought along extra efficiency and creative freedom in designing new products. Additive manufacturing enables us to create items rapidly and cheaper as one-offs and mitigate supply chain disruptions. Moreover, it allows for completely different product design that would otherwise not be possible with extractive manufacturing processes like CNC machining. Extractive manufacturing takes material away from a billet whereas additive manufacturing adds to the part as it is being made, hence the extra design freedom. By leveraging our additive manufacturing capabilities, we have designed a new subassembly that is being incorporated into one of our products, resulting in performance unparallelled by our competitors. We are also using it for production of standard parts in-house.

“Another popular topic is Industry 4.0, which refers to smart manufacturing. In line with it, we have introduced semi-automated and fully automated programming for our CNC machines. I believe this is something that is currently expected from most businesses. So far, it has helped us reduce programming setup time, increase our production volumes, and make us more agile. Besides, we have implemented a few collaborative robots in some of our sites, which are particularly brilliant at completing repetitive manufacturing operations. These robots provide the added benefit of allowing our staff to focus on higher-value activities. Furthermore, we are planning to invest in a proof of concept for additional automation, including offline Coordinate Measuring Machines (CMM) to inspect parts and ensure they have the correct dimensions. We are also looking at automating both low-batch and high-batch machining and working towards a paperless shop floor. All in all, there are a lot of exciting developments coming up, but we are focusing our efforts on the areas that we think most people would expect us to develop,” he elaborates.

for our CNC machines. I believe this is something that is currently expected from most businesses. So far, it has helped us reduce programming setup time, increase our production volumes, and make us more agile. Besides, we have implemented a few collaborative robots in some of our sites, which are particularly brilliant at completing repetitive manufacturing operations. These robots provide the added benefit of allowing our staff to focus on higher-value activities. Furthermore, we are planning to invest in a proof of concept for additional automation, including offline Coordinate Measuring Machines (CMM) to inspect parts and ensure they have the correct dimensions. We are also looking at automating both low-batch and high-batch machining and working towards a paperless shop floor. All in all, there are a lot of exciting developments coming up, but we are focusing our efforts on the areas that we think most people would expect us to develop,” he elaborates.

One such area is, of course, sustainability, which ranks especially high on John Crane’s agenda. Mike lays out the many ways in which the company works to reduce not only its own but also its customers’ emissions. “As a business of the wider Smiths Group, our shareholders expect and want us to act in a sustainable and environmentally friendly way, as do our customers. Thus, we are very motivated in the area, with a Net Zero commitment and approved Science Based Targets Initiative (SBTI) goal. We are working on reducing our Scope 1, 2, and 3 emissions, corresponding to those emitted by our own operations, by our supply chain, and downstream into our customers. “

Sustainability initiatives

“Our automation and process standardization efforts improve our operational efficiency, thereby reducing waste and energy consumption. We also have an energy conservation campaign in place called ‘Turn it Off’, aiming to change behaviors across our entire workforce regarding simple things like ensuring that nothing is left running when it isn’t needed. Each site conducts a full greenhouse gas inventory to create a decarbonization plan for Scope 1 and 2 emissions. We have implemented many other sustainability initiatives, including installing a solar system at one site and commissioning a second one, and using renewable energy wherever possible to reduce our Scope 2 emissions. Within my team, we are considering rationalizing our raw materials use, which isn’t only commercially beneficial, but also sustainable, as it limits the impact of raw material extraction, processing, and transportation,” he continues.

“Less evidently, our day job in itself promotes sustainability. Our sealing products are designed to help our customers move fluids, such as gas and oil, without leakage. Hence, our operations evolve around reducing Scope 4 emissions, as we constantly strive to help our customers reduce their methane emissions. To this end, we are developing hydrogen seals, empowering clients to switch from petrochemicals to more sustainable fluids. In 2023, we were awarded almost £1 million in grant funding from the UK Government’s Carbon Capture, Usage and Storage (CCUS) Innovation competition. Subsequently, we began working with Cranfield University and the University of Edinburgh to develop seals for high-temperature and supercritical CO2 power cycles to meet future energy requirements,” Mike ends.

By combining investments in cutting-edge technologies with game-changing sustainability initiatives, John Crane empowers industry professionals to optimize their operations for a greener future.