From bespoke solutions to Robopod, Mechtech Automation Group is transforming processes

Mechtech Automation Group is a collection of brands that incorporate Mechatronic’s world-class automation manufacturing solutions, including Robopod’s reconfigurable, plug and play robotic systems, integrated with smart factory innovations, and Mechatronic, specializing in the development of bespoke automated solutions tailored to their customers specific requirements.

Working collaboratively with its customers, the group’s focus is to design, manufacture and deliver flexible, modular, automation solutions that not only increase the performance and productivity of its customers’ operations but are fully supported and serviced post-delivery.

“Mechatronic began operating in 1988, from a small factory unit in Sheldon, before moving to a purpose-built facility in Kings Norton in 2011,” begins Tony Parker-Watkins, Managing Director. “Generally speaking, we provide factory and process automation for some of the world’s largest blue chip companies to local UK based SME’s, producing everything from medical devices, electronic devices, automotive HUD assembly lines to exterior and interior plastic molded parts. While our heritage lies in the UK automotive and industrial industries sectors, over the past ten years we have worked tirelessly to diversify our markets sector to help enable growth and now operate global markets from the USA, to Europe and Malaysia, operating in sectors including medical device, aerospace, plastics, electronics, metal processing and electrification.

“Mechatronic began operating in 1988, from a small factory unit in Sheldon, before moving to a purpose-built facility in Kings Norton in 2011,” begins Tony Parker-Watkins, Managing Director. “Generally speaking, we provide factory and process automation for some of the world’s largest blue chip companies to local UK based SME’s, producing everything from medical devices, electronic devices, automotive HUD assembly lines to exterior and interior plastic molded parts. While our heritage lies in the UK automotive and industrial industries sectors, over the past ten years we have worked tirelessly to diversify our markets sector to help enable growth and now operate global markets from the USA, to Europe and Malaysia, operating in sectors including medical device, aerospace, plastics, electronics, metal processing and electrification.

“Our expertise lies in bespoke automation, which is where Mechtech grew our knowledge and experience in different types of equipment and technologies, whether it be robotics, assembly benches, or assembly machines, every aspect of the design is tailored to the customers’ needs. We work almost exclusively in-house, from initial applications and 2D or 3D simulations at the proposal stage, right through to user specifications, automation assembly, and project delivery. Each machine is even fitted with our own innovative software and control system, making us a one-stop shop for all automation needs.

Plug and play solution

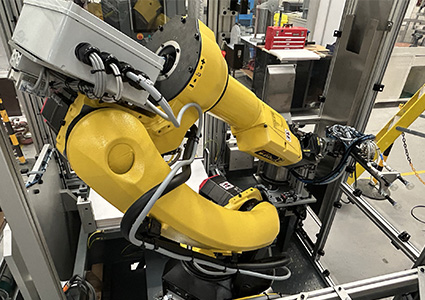

“We get involved with anything from manual assembly-built assist benches all the way through to fully automated robotic production lines,” he reiterates. “Until 2011, Mechtech Automation Group was predominantly involved with bespoke solutions, but this status changed in 2015 with the development and introduction of Robopod, our first standardized, ‘robot in a box’ solution. Robopod offers plug-and-play capabilities, enabling our customers to produce parts or automate a process within an hour of receiving the product on their shop floor; it’s freestanding, portable and uses minimal footprint on the shop floor, all it requires is to plug in power and air for prompt installation and once connected you are ready to start.

“Within its first year, Robopod generated sales of around £1.7 million and today, these sales equate to around 50-to-60 percent of our complete revenue. As we approach the pod’s tenth anniversary in 2025, we’re now in the Pod’s third generation of design with a standard software package that is not only simple to use but is also strengthened with every project undertaken. Robopod’s focus over the next 12 months is to explore a further update that focuses on the aesthetics to ensure the sleek appearance of the pod when in operation.

“Robopod is entirely unique in that it can be programmed to complete a range of applications, such as assembly, ultrasonic welding, inspection, polishing, and component processing. For customers with high varieties of different products, the pod offers flexible modular automation, with the ability to add or remove automation by adding an extra pod or tailoring each pod to a specific task within a series.”

Tony continues: “One of Robopod’s key differentiators from other similar products on the market is the fact that Robopod can be reconfigured. We can take a Pod back from a customer facility once a product line or process has become obsolete and retool it to do something completely different, protecting the customers investment of the industrial 6 axis or SCARA robot, pod chassis, control & pneumatic system. This also applies to our software, which can be reprogrammed if the customers’ process or application changes, offering total flexibility.

Product portfolio

“Furthermore, the Robopod control systems also have the capability to enable our customer secure remote dial in function that can be viewed on a mobile device or desk top PC. Our customers can remotely access securely the main home screen to collect maintenance, fault finding, operation or OEE data from anywhere in the world.

“With collaborative robotics coming into play, our product portfolio has grown to include complementary and additional products for Robopod. Aside from increased connectivity options, we also now offer two sizes of the pod: 1.5 meters by 1.6 meters or 2.1 meters by 2.1 meters.”

2018 saw Robopod introduce a new product to the market called Tendapod. This product was revolutionary providing an ‘Off the Shelf – reconfigurable’ robotic CNC, CMM machine tending solution. Due to the slim design, and the long arm reach of the robot, Tendpod provided customers the ability to dual tend processes or machine. “On one side there could be a CNC machine and the other a cleaning station, CMM or debur station, enabling secondary process to be automated giving greater justification for the use of robotics with our customers facility and allow the redeployment of staff from simple load/unload tasks to more complex value-added process that can’t be automated.

“A key design feature for Tendapod was to have internal work in progress (WIP) built within the solution and so Tendapod’s tote or pallet vertical store provides hours of unmanned production time and delivers increased productivity and efficiency.”

Expanding range

“I am extremely proud of our professional team here at Mechtech Automation Group and how we operate as a business. We’re an SME with a big business mentality, that works in strict accordance with our ISO 9001 standards. The team understands the importance of supporting our customers here during the design and build or out in the field, and so have a strong focus on customer support with a dedicated service and support team to look after any breakdown, machine warranties, and service level agreements. Mechtech ‘s reputation is excellent for winning repeat business and that can only be attributed to the hard work and dedication of the whole Mechtech Automation Group team.

As our conversation ends, we ask Tony what the future holds for Mechtech Automation Group and Mechatronic. “With a robust requirement for compact, smart, flexible automated robotic solutions, our focus will be to grow the Robopod brand and develop its product range to increase its technology integration and ‘smart factory’ offering, provide greater functionality with an improved smart control interface, be more aesthetically pleasing in design and become the leading solution for robotic automated systems and production lines. Mechtech will continue to design and build bespoke solutions, as this area of the business enables Mechtech to create innovation and develop a greater understanding of new technologies. Across the group, we’re constantly monitoring industry trends as technology evolves, and will leverage our skill set and expertise to stay ahead of the curve.”