From boat molds to spacecraft components, Janicki Industries has grown beyond expectations

As a full-service engineering and manufacturing company, Janicki Industries (Janicki) designs and builds high-precision parts, tooling, prototypes, and assemblies for several sectors including aerospace, marine, space, military, wind energy, architecture, and transportation. Specializing in large, complex projects with demanding timelines, the business has earned a strong reputation in the industry since its foundation in 1993.

Janicki was founded by husband-and-wife team, Peter and Susan Janicki, who were joined by Peter’s brother, John Janicki, shortly after in 1994. The business originally built five-axis computer-driven mills with the intention of selling them to the marine industry, but instead, boat building companies enlisted Janicki to machine hull molds and plugs. Having created extremely precise CNC mills, Janicki revolutionized the boat manufacturing market by creating low-cost, accurate, and durable molds.

Janicki was founded by husband-and-wife team, Peter and Susan Janicki, who were joined by Peter’s brother, John Janicki, shortly after in 1994. The business originally built five-axis computer-driven mills with the intention of selling them to the marine industry, but instead, boat building companies enlisted Janicki to machine hull molds and plugs. Having created extremely precise CNC mills, Janicki revolutionized the boat manufacturing market by creating low-cost, accurate, and durable molds.

“We truly are a family of entrepreneurs,” opens John Janicki, President. “Upon leaving Poland, my grandfather started a logging business in the US and my brother started Janicki Industries, known back then as Janicki Machine Design, by leveraging his experience in the aerospace market. With family resources at hand, he jumpstarted the company and focused on simply taking care of customers, which has resulted in over 30 years of success.”

Janicki’s innovative technology and attention to detail caught the attention of the aerospace industry and it was soon tasked with developing commercial aerospace tools. With a strong focus on research and development (R&D), its dedicated team quickly became experts in composite fabrication and prototyping.

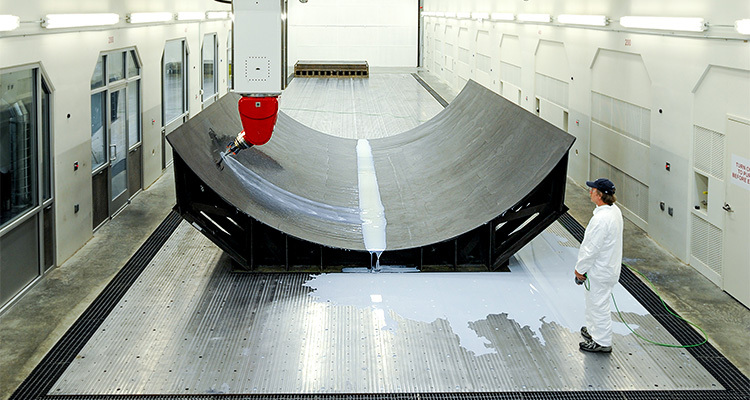

As its capabilities evolved, Janicki expanded its market reach to a variety of industries. Today, it boasts a diverse product portfolio ranging from yachts and wind energy blades to fighter jets and rockets. Through R&D, the business continuously pushes the boundaries of composite fabrication materials and techniques in response to evolving customer demands.

“I’d describe Janicki as an engineering company that also manufactures,” John states. “We’re a Tier 1 aerospace company, making parts and components for assemblies that go directly onto vehicles, predominantly in the defense and space industry. With engineers on the floor alongside our technicians, we take a collaborative approach to finding solutions to complex tasks.

“We started off in the marine industry with the idea of building and selling machines, but we quickly diversified into producing tooling and large-scale prototype parts. We’ve produced full-scale prototype windmill blades, for instance, and on the tooling side, we were heavily involved with producing composite tooling for the 787, 777X, and C-Series aircraft. Specifically, we produced the tooling for the 777X’s spars, which are an incredible 105 feet long.

“While there are several companies making composite parts, few are capable of producing the very large parts that we specialize in,” John continues. “This factor sparked interest from the space market, particularly for parts used for launching, as these are a crucial aspect of the aircraft but only used once, as they are released at a certain point during the launch. As you can imagine, these parts have very specific requirements, but our expertise in machining both aluminum and stainless steel means we can produce parts with optimal results.”

Turning to Janicki’s manufacturing facilities, John explains: “We’re vertically integrated, which bolsters our ability to produce parts for the structure of any aircraft or space vehicle. We have a strong research and development team, building on decades of experience in composite manufacturing.

“When it comes to quality, we conduct stress testing to identify potential problems. We analyze how things operate and stretch the limits of what we can do with the materials to see how they are impacted by certain conditions. We also purposely place defects on test items or break parts to identify where we can modify the design to make it more durable or easier to build, for example.”

In addition to its existing sites, Janicki has recently invested in a new facility specifically for an aerospace program. “We won a significant contract in 2022, which required a new building with unique specifications and a large manufacturing space,” John elaborates. “At 180,000 square feet, we’ve got a vast area with new equipment to facilitate this project.

“Due to inflation and supply chain shortages, combined with our schedule requirements, we decided to construct the entire site from timber. Considering our family history in the timber industry, this was a nice way to pay homage to our legacy while meeting more modern requirements and navigating issues within the supply chain. This project has been a joy to work on and the results are beautiful. It is now a welcoming and fully operational site.”

As our conversation draws to a close, talk turns to Janicki’s growth strategy and plans for the future. “We’re a small family business and we want to stay that way, rather than growing to a level that means we cannot maintain the quality service and innovative solutions we’ve become known for,” John proposes. “However, we need to have a variety of projects and programs to keep the company healthy, as the aerospace industry is particularly susceptible to delays, which can have a huge impact on a small business.

“We can typically have up to 100 projects ongoing concurrently in the tooling business, although we sometimes have a project that requires a significant portion of resources. With demand predicted to increase in the coming years, we are looking to grow through finding talented people, and we’ve ramped up our training programs and internal systems to improve the onboarding process. We’re also working with local schools to raise awareness of careers in manufacturing and get people interested in engineering from an early age.

“In terms of our operations, we’re currently involved with a series of training programs to enhance our capabilities when it comes to full-size assemblies,” John concludes. “This will enable us to complete full assembly of components and parts for clients across a number of sectors, but particularly in the defense market and both the public and private space industries.”