From data overload to operational intelligence: How semiconductor manufacturers are connecting the dots

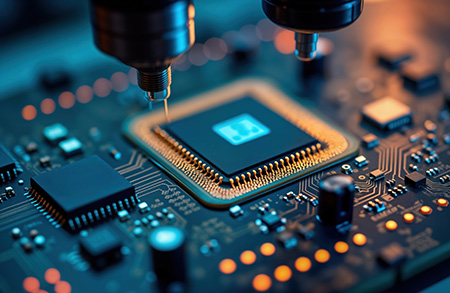

Semiconductor fabrication facilities generate a staggering volume and variety of data, from sensor streams and metrology reports to test logs and process diagnostics. Yet much of this data remains trapped in silos, preventing engineers from acting quickly when quality, yield, or performance issues arise.

In this article, we’ll explore how analyzing diverse data sources using a visual data science platform can unlock faster troubleshooting, smarter cross-functional collaboration, and continuous improvement.

Challenges facing semiconductor manufacturers

According to a recent study by Spotfire®, a business unit of Cloud Software Group, 30 percent of global organizations lack the right internal skills to analyze data, while the same amount are still struggling to understand which data is relevant and useful to them.

According to a recent study by Spotfire®, a business unit of Cloud Software Group, 30 percent of global organizations lack the right internal skills to analyze data, while the same amount are still struggling to understand which data is relevant and useful to them.

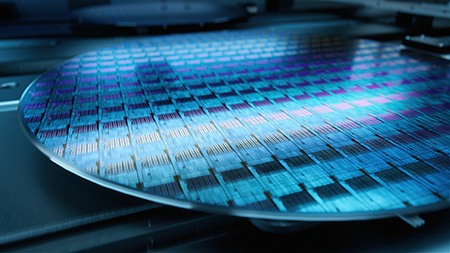

This is a big challenge in semiconductor manufacturing. Leading-edge semiconductor companies currently generate several petabytes of data per day. Still, they are only able to actively deal with a fraction of this data stream due to limited resources, in both tools and workforce skillsets.

As such, manufacturers face daily challenges, such as identifying the root causes of yield loss. With thousands of wafers processed daily and millions of test data points collected, pinpointing why yield dropped, even slightly, can feel like finding a needle in a haystack. A single piece of faulty equipment, for example, can trigger widespread production issues, scrap costs, and downtime. Likewise, data silos across test, metrology, process, and equipment logs make it hard to track how early-stage variables impact final product performance.

Turn data overload into a competitive edge

Visual data science can offer the ideal solution. By combining interactive data exploration, advanced data science techniques, and AI, it is possible to unleash human expertise and creativity to accelerate insight and decision-making in complex data-driven industries like high-tech manufacturing. It provides a clear and intuitive representation of complex data at speed, enabling users to slice, filter, drill, link, and explore technical data from anywhere.

Spotfire® offers a cutting-edge visual data science solution. With an AI-powered recommendations engine, Spotfire® suggests the best visuals to uncover relationships and augment analysis content and understanding for users. From custom visuals and calculations to adding updated analytics and reusing pipelines with future data, the platform makes it easier for users to understand complex information and derive insights for current and future operations and decision making.

The Spotfire® visual data science platform helps engineers quickly detect outliers, wafer patterns, and anomalies, accelerating root cause analysis from days to a matter of minutes. Analyzing historical equipment data, process logs, and real-time data allows engineers to intervene proactively, thereby avoiding unexpected breakdowns. A unified, no-code/low-code analytics environment lets teams correlate diverse data sets, from raw materials to electrical test, enabling faster and more accurate decision-making throughout the process flow.

Visual data science powers the field

Visual data science meets engineers where they are, empowering people in the field to make decisions with one click. Unlike traditional BI tools that lack the power needed for engineers, visual data science offers the latest in data science and statistical analysis while being more flexible and easier to use than specialist tools.

Visual data science meets engineers where they are, empowering people in the field to make decisions with one click. Unlike traditional BI tools that lack the power needed for engineers, visual data science offers the latest in data science and statistical analysis while being more flexible and easier to use than specialist tools.

By combining visualizations and advanced analytics, engineers can find industry-specific solutions that the human mind or computers can’t solve alone, enabling them to use their own experience and understanding to see what’s happening in data quickly.

Visual data uncovers hidden insights, enabling production issues to be addressed and product quality improved. It can predict equipment failures and maintenance needs, based on historical data, to reduce unexpected breakdowns, extend equipment life, and decrease maintenance costs, thereby maximizing factory uptime and increasing operational efficiency.

Users can rapidly identify and adjust to operational needs, enabling the sharing of insights across the organization and fostering better teamwork and cross-functional collaboration.

Visual data facilitates product development, supports strategic planning, and improves operational decisions. Advanced functionality includes connectivity to real-time systems and analysis, integration of structured, semi-structured, and unstructured data, no-code/low-code transformation tools, interactive drilldowns, and wafer visualizations.

Thanks to faster root cause analysis and quicker time-to-insight, the Spotfire® visual data science platform delivers real business impact.

Discover the data advantage today.

Article sponsored by Spotfire®