From visionary designs to intelligent automation: discover Robinson Helicopter Company’s journey in the civil aviation sector

For five decades, Robinson Helicopter Company (Robinson) has been designing and manufacturing some of the most dependable helicopters, enabling owners and operators to perform difficult missions all over the world. Moreover, the business is known for its factory overhaul program for older aircraft. By delivering safety-enhancing technologies, such as crash-resistant fuel-cell tanks, 4K cockpit video cameras, autopilot systems, and NVG-compatible cockpits, Robinson has positioned itself at the forefront of the helicopter industry. The vertically integrated company performs all aspects of helicopter production, from designing to manufacturing, assembling, inspecting, and flight testing. To ensure the highest quality and maximize efficiency, Robinson’s skilled workforce manufactures nearly 80 percent of its parts in-house.

President and CEO David Smith explains how Robinson developed a competitive edge throughout the course of its existence. “Robinson is the only major helicopter manufacturer in the world that focuses solely on civil products, as all of our peers provide a mix of defense and civil products. Frank Robinson, the company’s Founder, recognized the value of a personal helicopter that people passionate about general aviation could afford and safely operate. So, he spent most of his career prior to establishing Robinson developing the aircraft in his mind and on drawings. I find it amazing that he envisioned this idea early in his life and was able to realize it in his 40s when he founded the company. Despite facing many challenges, such as energy costs, recessions, and business risks associated with aviation, Robinson grew through the decades following the certification of our two-seat R22 aircraft, which we still produce today. Frank and his growing team enhanced our four-seat aircraft, making it even more versatile for various missions and utility applications, such as tourism, surveying, medical, and more.

President and CEO David Smith explains how Robinson developed a competitive edge throughout the course of its existence. “Robinson is the only major helicopter manufacturer in the world that focuses solely on civil products, as all of our peers provide a mix of defense and civil products. Frank Robinson, the company’s Founder, recognized the value of a personal helicopter that people passionate about general aviation could afford and safely operate. So, he spent most of his career prior to establishing Robinson developing the aircraft in his mind and on drawings. I find it amazing that he envisioned this idea early in his life and was able to realize it in his 40s when he founded the company. Despite facing many challenges, such as energy costs, recessions, and business risks associated with aviation, Robinson grew through the decades following the certification of our two-seat R22 aircraft, which we still produce today. Frank and his growing team enhanced our four-seat aircraft, making it even more versatile for various missions and utility applications, such as tourism, surveying, medical, and more.

“In the 2000s, Frank focused on developing the R66 before his retirement. The R66, powered by a Rolls Royce turbine engine, has been in production for about 14 years and is now our most popular product. What sets us apart is our focus on civil products, which keeps our team constantly pressured to maintain acquisition and operating costs at the lowest in the industry, thus making it possible for small businesses to operate season after season. But our other unique characteristic is that we are the most vertically integrated manufacturer in aviation. We bring raw materials in and produce aircraft on the other side of the facility, which is a rare approach in the industry as companies strive to make their products more cost-competitive. I think that our 50-year journey has proven that we can produce helicopters affordably, even in high-cost places like Southern California, by making smart investments and choosing the right team,” he enlightens.

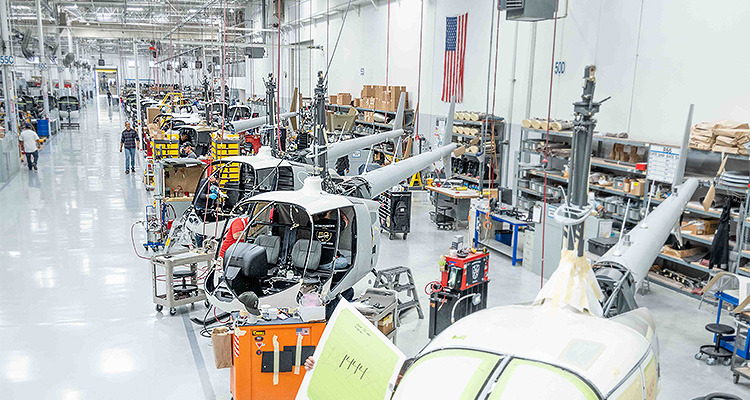

David goes on to describe Robinson’s production facilities and the tasks involved in creating its renowned aircraft. “In total, we have about 700,000 square feet of space dedicated to manufacturing our aircraft. Most of it is used for the production of new parts, while a smaller portion is used for the overhaul of pre-flown parts that need to be evaluated before returning to the fleet. All of the steps required to produce an aircraft take place in this facility, such as machine component production, water jet cutting, sheet metal forming, riveting and drilling of sheet metal and machine parts, welded components (we do both aluminum and steel welding), wire electrical discharge machining (EDM), and assembly of the entire hydraulic system, which is a difficult component to manufacture to aviation standards. Likewise, all the inspections necessary for each of these processes are done in-house, allowing us to optimize the size, weight, and cost of the product for our application. This level of vertical integration is unique in the industry, as the rest of the sector outsources this entire set of skills,” he says.

space dedicated to manufacturing our aircraft. Most of it is used for the production of new parts, while a smaller portion is used for the overhaul of pre-flown parts that need to be evaluated before returning to the fleet. All of the steps required to produce an aircraft take place in this facility, such as machine component production, water jet cutting, sheet metal forming, riveting and drilling of sheet metal and machine parts, welded components (we do both aluminum and steel welding), wire electrical discharge machining (EDM), and assembly of the entire hydraulic system, which is a difficult component to manufacture to aviation standards. Likewise, all the inspections necessary for each of these processes are done in-house, allowing us to optimize the size, weight, and cost of the product for our application. This level of vertical integration is unique in the industry, as the rest of the sector outsources this entire set of skills,” he says.

These processes are made more efficient with the implementation of Smart Factory solutions and automation, as David points out: “Our investments in automation and intelligent manufacturing methods are focused on areas that have high injury and repetitive motion injury risks. We have seen success in implementing robot-assisted tasks, where technicians still load materials, observe, and manage the quality of the robots’ actions, but they are not fully replaced by the robots. Currently, we run on a custom-built ERP system that we have developed throughout our history. Furthermore, we are implementing a new ERP system that will provide us with additional insights through modern methods of data and variation analysis, and we are excited about the opportunities that data will bring. In the past 51 years, we have shown that we do not need to have the most cutting-edge manufacturing operation to successfully drive our business. Instead, we tried to keep the company simple, which then allowed us to improve our quality, scale and efficiencies. Now, opportunities to incorporate robotics and automation will add to what we have already built over the years,” he states.

Nonetheless, David emphasizes that automation will not completely replace human labor, as the company addresses industry-wide labor shortages by bringing in people at the grassroots level. “Being based near Los Angeles, we have access to a large talent pool of recent graduates. We do our best to attract those who are interested in aviation and offer them positions in a few of our key areas, where they can receive on-the-job training and become familiar with our systems, parts, and the basics of working in a manufacturing environment,” he concludes. “In this way, they can evaluate whether they want to stay with us, moving forward.”