German RepRap GmbH

Made in Germany

Manufacturing Today Europe spoke to Lena Wietfeld, Head of Marketing at German RepRap, to get some insight into how its future-oriented 3D printing technologies are helping its customers create some astonishing solutions.

“Originally founded as German RepRap Foundation (GRRF) in 2010, since that time we have been developing our X-Series 3D Printers based on Fused Filament Fabrication (FFF) technology. In 2016, we then launched the newly developed and globally unique Liquid Additive Manufacturing Technology (LAM),” she began. “The special feature of all our printers is their Open Source Platform, which makes it possible to use a variety of materials for printing. New consumables are constantly being tested and added to our product range. Thus, our customers are not bound by specific rules and can adapt the print job to their personal requirements and we can take their individual wishes into account.”

The printer solutions from German RepRap are marketed in combination with software, filaments, and accessories – directly as well as through a worldwide network of qualified distributors. “Our international network of distribution partners means we are local to our customers wherever they are in the world, and our close working relationships with them is one of the secrets of our success,” Lena highlighted. “Close and direct contact with our clients and industrial partners is particularly important, as this is the only way to guarantee concentrated know-how in products and solutions. We only want to offer innovative and high-quality products, and so our daily work is based on enthusiasm, tackling challenges and looking for  individual solutions. That is what our customers, business partners and colleagues appreciate about us.”

individual solutions. That is what our customers, business partners and colleagues appreciate about us.”

With the overall ambition to make it easier for a wide variety of companies to produce 3D printed components, German RepRap is able to assist its clients with the development process, thanks to its high quality and unique equipment. Lena explained that it is also continuously improving its machines and finding new technologies for its printers, some of which are proving quite revolutionary in the industry. She gave an example: “With our latest development, the LAM process, liquids such as silicone rubber can also be processed, which is an absolute game changer and the first machine worldwide with this technology.”

LAM differs from an FFF printer in that its material is not melted and solidified again, but is liquid, and vulcanised under heat exposure. That means it is fully thermally crosslinked, and the individual layers that the printer deposits are firmly connected to each other. In this way, it is possible to produce components that have almost the same properties as injection-moulded parts – a clear advantage because aspects of the 3D-printed prototype can directly be transferred to injection-moulded serial parts.

“In addition, this is also very interesting for the development of new customer groups, since the process, even without an investment in tools or moulds, makes lot sizes of n = 1 possible and economical,” added Lena, before continuing with further advantages offered by LAM technology. “It has interesting possibilities for the optimisation of product design, plus it offers a lot more options for customisation, as complex geometries that previously weren’t possible to process with conventional production technologies, can now be achieved.” In addition, users benefit from a shorter time-to-market.

German RepRap’s 3D printer for LAM is the L320, which is extremely stable, and has been adapted to the high demands of industrial continuous operation. “It has proven its reliability in continuous operation in extensive tests and pilot applications in practice, Like the Quant-U project with ECCO for example,” noted Lena.

As the advantages of additive manufacturing are becoming more universally recognised, organisations from an increasingly varied number of sectors are seeking solutions, and Lena agreed that the technology is becoming indispensable for the majority of the manufacturing sector and continues to gain importance. “For our customers, this means creating new opportunities for production, new ideas and new innovations. It is impressive that almost every industry now uses 3D printers, from automotive and aerospace to medical, electronics and even art and fashion.”

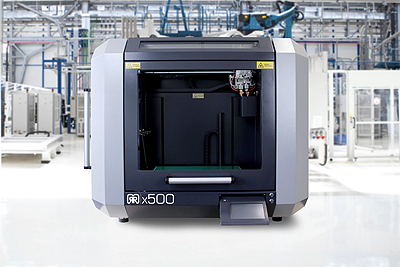

Lena continued with examples: “A manufacturer in the automotive sector, Sika Automotive, is using the German RepRap x500 to speed up development processes for functional structural components. This enables the company to deliver plastic parts for smaller series, and promises great potential for the company to explore a range of different materials.”

The x500 product referred to above is a robust 3D Printer for industrial use, plus German RepRap was the first company in Germany to launch a RepRap-based large-capacity 3D printer for industrial demands with the x1000. It also offers the x400 printers for smaller applications – these machines offer excellent performance and value, as one customer, automotive parts manufacturer TP Technische Dienstleistungen, has discovered. Company founder Thomas Pazulla realised the opportunities that offering additive manufacturing services would bring, and he started on this journey with one x400 3D printer from German RepRap.

The device proved very useful for many applications, and as Mr. Pazulla received more and more orders, he decided to purchase a second machine. Continuing on this path of expansion, today TP Technische Dienstleistungen runs a significant stable of German RepRap printers, which have opened up completely new possibilities for applications that, up until now, required injection molding. Since investing in these solutions, TP Technische Dienstleistungen has seen a significant increase in 3D printing orders involving small-to-medium lots of fused deposition molding (FDM) parts.

What these case studies illustrate is the possibilities that additive manufacturing offers with regards to more material varieties and optimised technologies. “Companies from all industries will use the technology and adapt their processes,” Lena predicts. “It is not only prototyping anymore. We have cases where series production of 40,000 parts have been done with our  printers. Many people underestimate the technology and how important it will be in the future.”

printers. Many people underestimate the technology and how important it will be in the future.”

Anticipating that additive manufacturing will go from strength-to-strength, Lena noted that German RepRap maintains a very solution-oriented approach, assisting its customers as consultants and partners, and finding solutions for individual applications and requirements. “Our open material platform is important, since customers can experiment with whatever material they want. Also, we have a wide range of tested materials (even high temperature and abrasive or metal materials), where customers can get settings and information on how to use them best.

“If there is a solution with our technologies for your individual case, we will find it – we are extremely proactive in that way,” she concludes. “At German RepRap, innovation and experience go hand-in-hand.”