Global Markets React to China’s Rare Earth Export Limitations

Subscribe to our free newsletter today to keep up-to-date with the latest manufacturing news.

China has taken a sharp step in the escalating trade conflict with the United States by restricting exports of seven critical rare earth elements. These include dysprosium, terbium and samarium, which are used to produce permanent magnets essential in technologies ranging from electric vehicles to missile guidance systems.

The new rules, introduced by China’s Ministry of Commerce, come as Western governments place tighter controls on technology transfer and semiconductor access. Analysts see this as a signal that Beijing is prepared to assert economic power where it has the upper hand: the global materials market.

China’s control of the rare earth magnet market remains unrivaled

The scale of China’s dominance is significant. According to Adamas Intelligence, China produces 92 percent of the world’s rare earth magnets, while mining only 70 percent of global rare earth ore. This control is the result of decades of investment in refining, separation and magnet-making capabilities.

The seven rare earths targeted by the new restrictions of: dysprosium, terbium, samarium, praseodymium, neodymium, gadolinium and holmium – essential inputs in high-performance magnets. These magnets are found in a wide range of products including wind turbines, EV motors, hard drives, military radars and aerospace propulsion systems.

A single wind turbine may contain as much as 600 kilograms of rare earth magnets, while an electric vehicle contains between 1 and 2 kilograms. U.S. defense systems also rely on these materials for precision manufacturing in guided weapons and fighter jet actuators. Disruptions to supply could affect both industrial productivity and national security.

Past restrictions already show Beijing’s readiness to disrupt supply chains

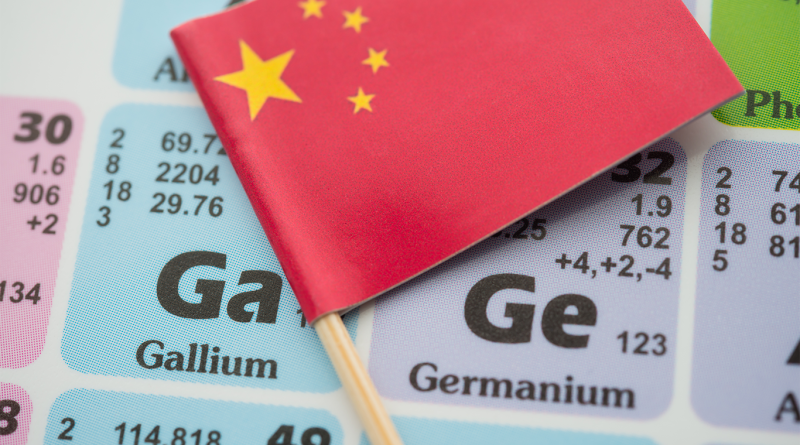

This is not the first time China has tightened control over critical materials. In July 2023, Beijing blocked exports of gallium and germanium, which are essential to chip and solar cell production.

While the latest rare earth rules are not a full ban, they require companies to report all transactions involving the seven listed elements to China’s Ministry of Commerce. This introduces red tape and may disincentivize buyers from relying on Chinese suppliers. The net effect is a tighter supply environment that introduces pricing uncertainty and inventory risks.

Prices are already rising. Dysprosium oxide increased from $295 per kilogram in early March to more than $330 in April. Similar trends are emerging for terbium oxide and neodymium-praseodymium alloys, which are widely used in electronics and energy technologies.

The U.S. and allies lack sufficient capacity to absorb the shortfall

Despite growing concern, the United States remains dependent on Chinese processors. MP Materials operates a rare earth mine in Mountain Pass, Calif., but still ships ore to China for separation. Lynas Rare Earths, the largest non-Chinese supplier, is based in Australia and also faces downstream bottlenecks.

Europe is also attempting to reduce reliance through the European Raw Materials Alliance, though projects remain in early phases. Global demand for rare earth magnets is expected to rise between 8 and 10 percent annually through 2035, according to Adamas Intelligence. This growth is driven by electric vehicles, clean energy infrastructure and robotics.

The restrictions on rare earth exports fit a broader trend of strategic trade measures. China has responded to U.S. sanctions on advanced computing and quantum hardware with its own controls over minerals and components. The message is clear: material dominance is now a form of geopolitical influence.