Green shoots of recovery in the supply chain By Kevin Hubbard

The automotive industry is a critical sector of the global economy that has faced numerous challenges over the last few years, including the Covid-19 pandemic and the semiconductor chip shortage. These challenges have significantly disrupted the automotive supply chain, causing delays in production, and leading to shortages of critical components. However, my team and I here at Evtec Automotive are seeing the green shoots of recovery as the industry adapts to the new normal and seeks to improve its operations, with OEMs making more accurate forecasting of production schedules which enable us, a Tier One supplier to manage our thousands of suppliers around the world.

One of the key areas where the automotive industry has experienced significant disruption is in the supply of semiconductor chips. These chips are essential components in modern cars, used in everything from powertrain management to infotainment systems. The pandemic and other factors such as a fire at a semiconductor manufacturing plant in Japan have led to shortages of these chips, causing production delays and reduced output. However, the industry is working to address these challenges, with many automakers increasing their orders and investing in new chip manufacturing facilities to secure their supply.

One of the key areas where the automotive industry has experienced significant disruption is in the supply of semiconductor chips. These chips are essential components in modern cars, used in everything from powertrain management to infotainment systems. The pandemic and other factors such as a fire at a semiconductor manufacturing plant in Japan have led to shortages of these chips, causing production delays and reduced output. However, the industry is working to address these challenges, with many automakers increasing their orders and investing in new chip manufacturing facilities to secure their supply.

Driving recovery

In addition to the chip shortage, the pandemic also led to a significant reduction in demand for new cars, as consumers faced economic uncertainty and reduced mobility and in the last two years there has been a significant move to the development of electric vehicles. This has caused automakers to adjust their production schedules and reduce capacity. However, as the global economy recovers and mobility returns to pre-pandemic levels, there are signs of increasing demand for new cars, which is driving the industry’s recovery.

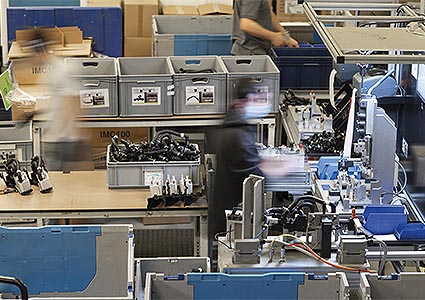

To meet this demand, we are working closely with automotive manufacturers across Europe, focusing on localizing supply and shortening supply chains to strengthen them, with more accurate production forecasting playing a critical role. By accurately predicting customer demand, automakers can adjust their production schedules and optimize their (and our) inventory levels, ensuring we can meet demand without overstocking. This can help reduce costs, improve operational efficiency, and ensure that customers receive the vehicles they want in a timely manner.

Long-term success

One way automakers are improving their customer demand forecasting is by leveraging data analytics and artificial intelligence (AI) tools. By analyzing historical sales data and other relevant information, these tools can identify trends and patterns that can inform demand forecasts. They can also adjust these forecasts in real-time based on changes in market conditions, such as shifts in consumer preferences or supply chain disruptions.

Another way automakers are improving their supply chain operations is by adopting new technologies such as blockchain and the Internet of Things (IoT). These technologies can help automate supply chain processes, reduce errors, and improve transparency, enabling automakers to better track their inventory levels and monitor their supply chain partners’ performance. This can help reduce the risk of delays and disruptions and ensure that automakers can deliver vehicles to customers on time.

Moreover, automakers are also focusing on developing more sustainable and environmentally friendly supply chain practices. This includes reducing their carbon footprint by using renewable energy sources in their manufacturing processes and logistics operations, working with Tier 1 suppliers such as us to on-shore component production and subassembly as well as promoting sustainable materials and recycling practices. By adopting these practices, automakers can improve their reputation with customers who are increasingly conscious of the environmental impact of their purchasing decisions.

In conclusion, while the automotive industry has faced significant challenges in recent times, there are green shoots of recovery as the industry adapts to the new normal and seeks to improve its operations. Improvements in customer demand forecasting, driven by data analytics and AI tools, are playing a critical role in this recovery. By accurately predicting customer demand and optimizing their supply chain operations, automakers can reduce costs, improve operational efficiency, and ensure that customers receive the vehicles they want in a timely manner. Additionally, by adopting new technologies, sustainable practices and working closely with us to build shorter, more robust supply chains, automotive OEMs can further improve their supply chain operations and position themselves for long-term success.

www.evtec-automotive.com

Kevin Hubbard is MD at Evtec Automotive, a UK-based group, that focuses on every aspect of the electric vehicle supply chain and the end-to-end lifecycle of EVs. Its mission is to source, make, deliver and then sustainably dispose of all EV technologies, driving social change and the adoption of zero-emission vehicles.