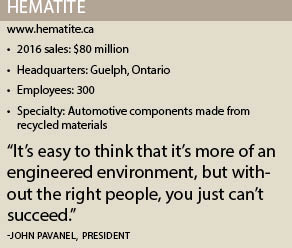

Hematite

The drive to be innovative and unique has kept Hematite successful for more than four decades, President John Pavanel says. “Everything about our service is different, from our people to our products to our processes and materials,” he says.

Based in Guelph, Ontario, Hematite manufactures high-quality, recycled products for the automotive industry, including acoustic, air flow and water deflection products. Pavanel’s father, Charlie Pavanel, started the company in 1974, after working as a chemical engineer for BF Goodrich.

When Pavanel set out on his own, he acquired a lighting firm. But Hematite found its current niche when it helped recycle interior trim materials for Ford Motor Co. The automaker had two facilities that were generating the waste, but did not have enough landfill space.

“We worked on with them with on a process to recycle that material,” John Pavanel recalls, noting that the pieces were used to make flooring and gasket materials before being applied toward noise, vibration and harshness (NVH) applications.

“We formed them into a barrier material for acoustic treatments in a car,” he says. Hematite grew to serve General Motors, Chrysler and Toyota with the products before moving into exterior products for acoustic and water management applications.

“That naturally progressed over the years into wheel arch liners and under body treatments,” he explains, noting that the market is currently strong for both, due to the need a better fuel economy. “You’re dealing with a lower coefficient of drag and airflow around the vehicle.”

Today, Hematite also serves Volkswagen and Honda and sets itself apart through its manufacturing. The company offers its customers thermal and compression molding, Pavanel says.

Hematite also distinguishes itself with the range of materials it uses, including thermal plastics, sheet molding compounds, glass mat material and fiberglass. “We like to have a full tool box available to our customers,” he says.

Location, Location, Location

Location, Location, Location

Hematite has facilities in Guelph and Brantford, Ontario, and recently broke ground on a 120,000-square-foot location in Englewood, Ohio. “That facility will come online before the end of the year,” Pavanel predicts.

The company also plans to open a location next year in Guanajuato, Mexico, that will span 80,000 square feet. Both of the locations will provide Hematite with logistics advantages, he says.

“You need to be closer to your customers, and that’s why Englewood is important to us,” Pavanel says. “With the amount of production that takes place in Mexico, we have to have a facility.”

A Lean Future

Hematite’s customers require high levels of quality, so it must maintain a strong focus on its manufacturing process. “It’s just a requirement of the business when you’re a smaller supplier,” Pavanel says.

“You just have a narrower margin of error,” he says, noting that the company has adopted lean manufacturing, and is in the process of implementing a lean culture. This drives Hematite’s employees to work together more and take better ownership of their work, Pavanel says.

“That lean culture is really the future of the business,” he explains, adding that the company employs two former Toyota employees who are lean experts. “We’ll work with them toward a lean culture. I think it’s going to be everything for us.”

Hematite also keeps its inventory low. Not only does it have disciplined staff members with the right mindset, “We have a cloud-based MRP system,” Pavanel says. “It’s turning out to be a wonderful tool.”

Good Influences

Pavanel joined Hematite in 1978. “As we started to develop the automotive business, I was the first new employee,” he recalls, noting that he always wanted to work alongside his father. “I respected the work he did.”

He also has respect for Hematite’s team. “It’s taken me some time to really understand how these businesses work, but at the end of the day, it’s easy to see the differences in the people you have to have in every area,” Pavanel says.

“They influence your daily success,” he adds, noting that this carries over into Hematite’s products, customer service and growth. “We have strong general managers for each location.

“Their priority is to grow and manage their people,” he says. “Everything flows from there. It’s easy to think that it’s more of an engineered environment, but without the right people, you just can’t succeed.”

Pavanel predicts a strong future for Hematite. However, it may see the automotive industry cool off in the near future, as it nears the end of a strong business cycle. “We’re optimistic, but we’re mindful of where we are,” he says.

But the company plans to keep growing. “We’re excited about our ability to provide innovative treatments – both interior and exterior,” he says. “There continues to be opportunities.”