How $3 Billion Investment Will Transform the US Battery Supply Chain for EVs

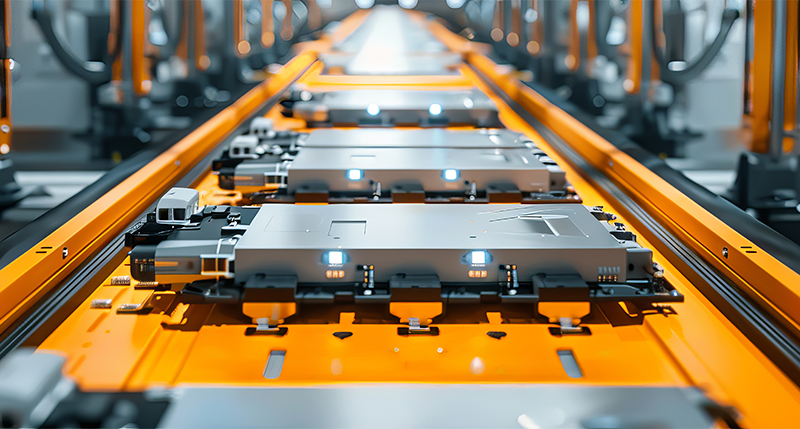

The United States has committed to a $3 billion initiative to expand domestic battery manufacturing, marking a significant move toward energy independence and the advancement of clean energy technologies. Administered by the Department of Energy (DOE), this investment will support 25 projects across 14 states, with a focus on producing critical battery materials like lithium, graphite, and manganese.

These efforts align with the Biden administration’s broader goal of securing the electric vehicle (EV) supply chain and reducing dependence on foreign imports, particularly from China. This initiative is expected to create over 12,000 jobs, driving innovation and benefiting disadvantaged communities while positioning the US as a global leader in battery technology.

The Strategic Importance of Battery Production

The growing importance of batteries extends beyond powering electric vehicles—they are a cornerstone of the nation’s energy infrastructure, supporting homes, businesses, and stabilizing the national grid. As the US transitions to clean energy sources, building an end-to-end domestic battery supply chain has become critical. Increasing domestic production helps minimize reliance on foreign suppliers, especially China, which currently dominates global battery material markets.

This shift is essential for both economic and national security, as a robust domestic battery industry reduces vulnerabilities in the supply chain and supports long-term energy goals. The ability to strengthen domestic capabilities enhances US competitiveness in the rapidly growing global renewable energy market.

Details of the DOE’s $3 Billion Investment

The DOE’s $3 billion investment will fund 25 projects designed to expand the production and recycling of critical battery materials. These projects will focus on increasing capacity for battery-grade minerals like lithium, graphite, and manganese while also building and retrofitting facilities to manufacture essential battery components.

This funding will create jobs, with over 8,000 construction positions and more than 4,000 long-term operating jobs projected. Notably, over half of the projects have signed Project Labor Agreements (PLAs), ensuring that these jobs are high-paying, unionized positions that benefit communities.

The private sector is expected to contribute an additional $16 billion, with the goal of accelerating the development of a secure domestic battery supply chain that can support the US’s growing demand for electric vehicles and renewable energy storage.The Role of Critical Minerals in Battery Production

Lithium, graphite, and manganese are vital to the production of advanced batteries for EVs and renewable energy storage. Lithium, commonly referred to as ‘white gold’, is essential for lithium-ion batteries, which are prized for their energy density and long life cycles. Graphite, meanwhile, is the primary material used in battery anodes, and manganese is utilized to boost battery performance and reduce costs.

The DOE’s funding is also aimed at increasing domestic processing capabilities for these materials, reducing US dependence on foreign imports, particularly from China. This initiative supports the creation of a circular economy, where battery components are recycled, contributing to a more sustainable supply chain.

Innovation and Future Technologies in Battery Manufacturing

The US investment in battery manufacturing is not just focused on scaling existing technologies but also on pioneering innovations that will drive the industry forward. Solid-state batteries, which replace liquid electrolytes with solid materials, offer significant improvements in energy density and safety compared to traditional lithium-ion batteries.

Lithium iron phosphate (LFP) batteries, known for their lower cost and greater stability, are also gaining momentum in EV applications. Additionally, the investment supports silicon-anode battery technologies, which could significantly boost battery capacity by replacing traditional graphite anodes.

These advancements are critical to maintaining US leadership in global battery technology, ensuring that the country stays at the forefront of energy storage innovations.

Economic and Environmental Impact

The immediate impact of the DOE’s investment is the creation of thousands of jobs in construction and manufacturing. With over 8,000 construction jobs and 4,000 operational positions projected, the battery industry will provide long-term employment opportunities across multiple states.

Beyond job creation, the projects funded by this initiative will contribute to building a sustainable circular economy. The focus on recycling battery components is essential for reducing the environmental impact of battery production. By recycling lithium, graphite, and other materials, the US can minimize the environmental footprint of battery manufacturing while securing a stable domestic supply.

This initiative also aligns with the nation’s clean energy goals, as advanced batteries are crucial for storing renewable energy from solar and wind sources. Expanding domestic battery production will accelerate the adoption of electric vehicles, reducing the country’s carbon emissions and advancing the broader goal of transitioning to a clean energy economy.

The US is positioning itself as a global leader in battery production with this $3 billion investment, securing its energy future while fostering innovation, job creation, and sustainability. As the world moves toward cleaner energy solutions, the ability to produce advanced batteries domestically will be a cornerstone of the nation’s economic and environmental strategy.

Sources: