How Byrna Technologies is capitalizing on increased demand for self-defense products

Founded in 2005, Byrna Technologies (Byrna) was created by an avid group of gun owners who came together with a common mission. COO, John Brasseur explains: “We realized that there was a critical need for a non-lethal self-defense option that could effectively stop a threat at a distance. This realization was not just an opportunity to create a new product, but a calling to address a deeply felt need in our society.

“From the earliest days of Byrna, our driving force has been the desire to save lives. We knew that to make a real impact, we needed to create a product that was not only safe and reliable but also accessible and easy to use. The continued development of Byrna launchers is fueled by the desire to provide people with the best self-defense options before they have to result to lethal force.

“Since its launch, the feedback we have received from our customers has been humbling and incredibly rewarding. Hearing stories of how our product has empowered individuals to protect themselves and their loved ones without causing irreversible harm, reaffirms our commitment to our mission and inspires us to continue innovating and expanding our product range.”

empowered individuals to protect themselves and their loved ones without causing irreversible harm, reaffirms our commitment to our mission and inspires us to continue innovating and expanding our product range.”

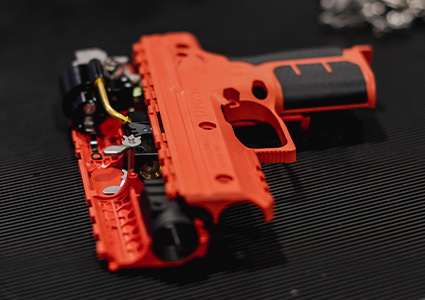

Having capitalized on the success of the initial offering, Byrna has since expanded its product range significantly. John elaborates: “Our products are all designed in Massachusetts by our internal research and development team. These designs are then manufactured in our factory in Ft Wayne, Indiana. We currently have two pistol models, the LE and SD, and two rifle models, the Mission 4 and TCR. We also design and manufacture our own ammunition to complement the launchers.

“The ammunition falls within two categories, training and defense. Training ammo helps the user to improve shot placement and acquisition timing. There are three types of training ammo we provide. Eco-Kinetic rounds are the only truly environmentally friendly .68-caliber rounds available on the market today. Kinetic projectiles are a (reusable) hard, solid plastic projectile that can be used for self-defense and practice. Thirdly, there’s Pro-Training Projectiles, which were developed to help law enforcement and civilians understand how our chemical irritant rounds can be used by simulating ballistic performance and cloud formation.

“As well as the Kinetic ammo which can also be used for defense, we have Pepper rounds, which are a two-piece frangible shell filled with a pepper powder, consisting of five percent OC/PAVA mixture. Upon impact the projectiles burst, creating a cloud of chemical irritant that rapidly disperses into the air to quickly incapacitate an attacker. Then there’s Max rounds, which were designed to have the maximum stopping power and consist of a two-piece frangible shell filled with a pepper powder, consisting of nine percent OC/CS mixture. We also make a full line of pepper spray products under our Bad Guy Repellent and our Fox Labs brands.”

Building awareness

John goes on to outline the remarkable year Byrna has just had: “The company’s popularity has surged thanks to significant marketing efforts to raise awareness of our products. One of Byrna’s main challenges is educating the public about our product and the advantages over traditional lethal self-defense options. Commercially available less-lethal products are relatively new to the US market, so building awareness of their benefits is crucial for our continued growth.

“Having spent 13 years at one of the largest and one of most successful firearms companies in the industry, I can see how this product offers an effective alternative to lethal force. The increased demand has led to a significant boost in our production capacity, from 4500 launchers in September 2023 to over 18,000 launchers per month in June, July, and August 2024. This growth has created over 40 new jobs at our Ft. Wayne factory and two new engineering positions at our Andover, Massachusetts headquarters.”

“Having spent 13 years at one of the largest and one of most successful firearms companies in the industry, I can see how this product offers an effective alternative to lethal force. The increased demand has led to a significant boost in our production capacity, from 4500 launchers in September 2023 to over 18,000 launchers per month in June, July, and August 2024. This growth has created over 40 new jobs at our Ft. Wayne factory and two new engineering positions at our Andover, Massachusetts headquarters.”

Facility upgrades

Implementing new technologies and continuing to innovate the production process has been key to maintaining the recent wave of growth and keeping up with increased demand. “Our US factory is only about four years old, so we are always adding new processes and equipment as we try to improve quality and efficiency. Most recently, we have introduced some pneumatic presses to help reduce the fatigue of our assembly team. We will be introducing some automated ammunition manufacturing equipment this winter, as we transition our ammunition production from our South Africa facility to our Fort Wayne facility. This equipment will consist of a material handling robot, a dosing station to dispense the powder into the shell, sonic welders that weld the shells together, and a vision system for quality inspection. This equipment will be housed in a newly constructed custom clean room that ensures our workers are not exposed to any of the irritant powders. This room will house several of these machines along with some new packaging equipment that will sort and package our ammunition products.”

Looking to the future, the company has bold ambitions which John highlights: “We endeavor to continue expanding and create more world-class non-lethal products. My goal is for us to lead in innovation, achieve manufacturing excellence, and maintain an unwavering commitment to being the best in our field. I also hope to see us expand both domestically and internationally, establishing new markets and a strong customer base that safeguards both the general public and law enforcement officers.”