How Byworth Boilers leverages its engineering excellence to meet sustainability demands

Byworth Boilers is committed to delivering highly fuel-efficient steam and hot water boiler solutions for industrial use. As the demand for sustainability grows, the company is evolving, not only to enhance results for its customers but also to help reduce emissions across industries.

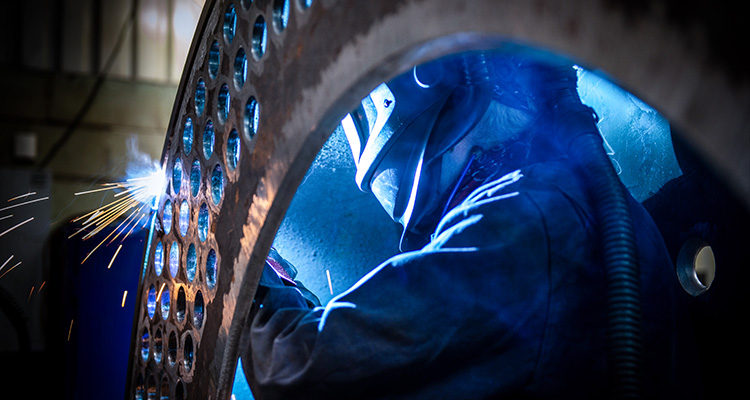

Steam boilers play a vital role in many industrial operations, and reliability is key to maximising efficiency and minimising downtime. Byworth understands this need and offers expert support across the entire lifecycle of its products, from installation and upgrades to planned maintenance and energy consulting.

With decades of experience in industrial, hot water, and waste heat recovery boilers, Byworth continues to lead with innovation. Its strong engineering foundation drives its research and development efforts, helping customers meet their sustainability targets and paving the way toward a cleaner, greener future.

With decades of experience in industrial, hot water, and waste heat recovery boilers, Byworth continues to lead with innovation. Its strong engineering foundation drives its research and development efforts, helping customers meet their sustainability targets and paving the way toward a cleaner, greener future.

We sat down with Rob Baldwin, Managing Director, to learn more about the company’s evolution. “Byworth was founded by my grandfather, Dennis Baldwin, in 1968,” Rob opens. “He started off in the growing industry, primarily growing chrysanthemums, but had always had an interest in engineering. He needed heat and steam for his growing operation and began to create solutions for greenhouse applications. Recognizing the better prospects on offer in the steam engineering business, he began to deploy more solutions for growers. In the early 1970s, the business evolved into manufacturing boilers and eventually began to offer comprehensive services like installation, spare parts, servicing, commissioning, customer training, and boiler plant hire.

“Today, almost 60 years later, I’m leading the business and representing my family’s third generation. Byworth now offers what we call the full boiler lifecycle; we have a comprehensive range of steam and hot water boilers, but we can also design bespoke boilers to meet specific customer needs. We support the manufacturing side of the business with a full solution offering, including commissioning and installing the boiler on-site, and then maintaining the boiler via our service department.

“We’re not just a business, but a partner to our customers throughout the boiler lifespan,” he states. “We offer training, spare parts, and advice on efficiency to ensure safe compliance and optimal long-term performance. On a different note, we provide temporary hire boilers and steam solutions, which are great to complement seasonal demand or increased capacity, as well as being a backup solution in the event of a breakdown.”

As the industry shifts towards greener solutions in pursuit of a more sustainable future, Byworth is leading the way in meeting these environmental challenges. “Through engineering design, we’ve made some dimensional changes to our products to allow for a more generous furnace size, which reduces the furnace heat release rate and lowers the flue gas emissions,” Robert explains. “We’re working closely with our burner suppliers to shift towards greener options and we’re also exploring hydrogen solutions, whether that’s mixed or pure hydrogen, as well as electric boilers.

“However, the infrastructure for hydrogen or electric boilers is not yet ready, and while I believe hydrogen boilers have a place in our future, there’s a lot of work to be done in terms of the grid and the relevant infrastructure before they can be a reliable solution. As we push towards green technologies, we must remember that reducing reliance on fossil fuels is not a quick process, and there will continue to be several constraints along the way. It’s most important that we move in the right direction and continue to challenge the status quo in the realm of emissions.”

Byworth has recently implemented some new procedures and processes to streamline its own operations. “The manufacturing sector is constantly evolving, and we recognize that we need to push our capabilities further and invest in new technologies and equipment to streamline our processes,” Rob reflects. “In 2020, we reconfigured our sites, remodeled our existing factory, and built an additional 20,000 square feet of manufacturing space. We’ve invested in new machinery to drive efficiency within the production line, and we’ve enhanced the entire process from raw material coming into the factory, to leaving as a fully assembled, fully packaged boiler.

we recognize that we need to push our capabilities further and invest in new technologies and equipment to streamline our processes,” Rob reflects. “In 2020, we reconfigured our sites, remodeled our existing factory, and built an additional 20,000 square feet of manufacturing space. We’ve invested in new machinery to drive efficiency within the production line, and we’ve enhanced the entire process from raw material coming into the factory, to leaving as a fully assembled, fully packaged boiler.

“We’re also upgrading our internal systems, from inventory management to computer systems, to further increase overall efficiency. As we want to bring our supply chain to the center of our operations, we’re currently building another factory, with a longer-term goal to launch an e-commerce offering.”

Aside from investments in its facilities and processes, Byworth is also continually investing in its people. “We’re really proud of our apprenticeship program, and although we’ve always had a handful of apprentices working in the business over the last 20 years or so, we’ve accelerated the scheme over the last five-to-six years,” Rob explains. “We’ve made the program more robust and partnered with a local college to refine the courses offered, ensuring they are both challenging and relevant. We currently have around 16 apprentices across the business, as well as four employees doing degree-level apprenticeships.

“Apprenticeships are a fantastic thing for us to offer our people, and they help with recruiting and retaining talent, especially given the skills shortage in the UK. Most of our people are keen to learn and challenge themselves, and we’re passionate about supporting them as together, we’re pushing the boundaries of what’s possible in our industry.”

To close our conversation, Rob shares his vision for Byworth’s future. “We want to be a long-term partner to our customers throughout their boiler’s lifecycle,” he concludes. “UK manufacturers are increasingly facing new and existing challenges, but it’s important that we pick up a bigger share of the cost as we continue to place customers at the heart of everything we do. Over the next five years, we’ll challenge our internal manufacturing processes to drive further efficiency, scale new technologies, and create an upgraded, more reliable product that serves customers both today and tomorrow as we move towards greener solutions.”