How fabricator Millerbernd forged an industry-wide reputation

It’s the eve of a significant milestone for Millerbernd Manufacturing Company (Millerbernd), a heavy metal fabricating company located in Winsted, Minnesota. Founded in 1933, the company is set to celebrate 90 years of operation next year – a period in which it has forged a reputation throughout the industry for service quality, product quality, delivery, and cost.

Within Millerbernd, business broadly falls into two distinct units. The first, known as the company’s transportation unit, includes standard, custom, and innovative light poles and traffic signal structures for customers working with US Departments of Transportation. Operating across 37 states, each with varying design criteria and calculations, Millerbernd’s professional engineering delivers products specified to individual markets.

“We provide support from design, all the way through fabrication and delivery to site,” comments Isaac Marceau, Vice President of Sales and Marketing for Millerbernd’s transportation unit. “Our focus on DoT gives us a deep understanding of our markets. We believe our products offer strong value relative to our competitors, and we focus on product specifications, customer service, and fulfilling our promises to our customers.

“Governing agencies are continually updating their criteria, which means states are always in the process of updating their products,” he adds. “Likewise, high-wind-speed states will have different requirements to those further inland. Therefore, we’ll work closely with DoT engineers on new designs, giving our input for ease of manufacturability, in order to maximize our own productivity for their specific location.”

“Governing agencies are continually updating their criteria, which means states are always in the process of updating their products,” he adds. “Likewise, high-wind-speed states will have different requirements to those further inland. Therefore, we’ll work closely with DoT engineers on new designs, giving our input for ease of manufacturability, in order to maximize our own productivity for their specific location.”

New facility

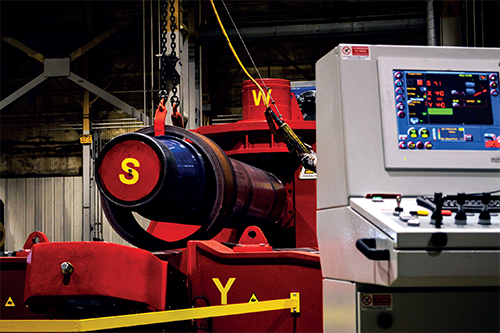

The second of Millerbernd’s business units encompasses rolled rings and cylinders, and accessory components for Tier 1, Tier 2, and OEM manufacturing companies. Ben Ostarello, Director of Sales for the unit, outlines its three distinguishing qualities amid a competitive field.

“First, we deliver scalable solutions; mill through delivery, partnering directly with mills where needed to get the best price and best product for our customers,” he comments. “Many of our customers don’t really understand our own material requirements, whether its cross-sectional size, available grades, or more economical mill runs. We partner with OEMs to help them understand what’s best for their application.

“Second, we focus on our core markets: construction equipment, defense, power generation, HVAC, and wind towers,” Ben continues. “Third, we offer flash-weld rings and cylinders, which deliver a stronger weld than standard processes, without filler material, at a fraction of the price. We also explore ways to improve efficiency and eliminate waste for our OEM customers, providing them cost savings over more common manufacturing methods. Most of our customers conduct their own design work in-house, and then come to us with a finished product. We help them to tweak those designs, thereby establishing long-term win-win relationships within our business.”

Like all industries, manufacturing was rocked by the arrival of Covid-19 in 2020, as global supply chains ground to a halt. But amid the chaos, Millerbernd quietly went about its business. In 2021, the company opened a state-of-the-art 110,000-square-foot facility at its Winsted site, which now houses its ring and cylinder division. The addition brings Millerbernd’s total manufacturing footprint to 600,000 square feet, provides a further 10,000 square feet of office facilities, and frees up previously occupied space on the factory floor.

“With this latest addition, we have all of our machining, forming, and welding services under one roof,” Ben comments. “The move has also allowed us to invest in new equipment, including a new robotic mega turn cell, a robotic Samsung machining center, a robotic grinding cell, and a new 13-foot wide Davi four-roll plate roller. This will help us to build additional capacity for our OEM business partners. We also have relative flexibility to further expand the building as our needs evolve.”

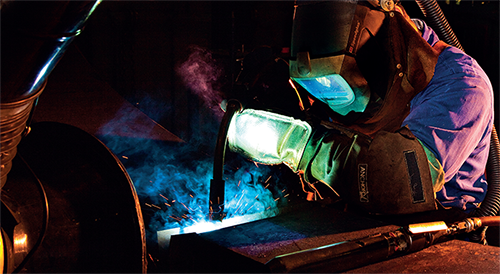

Comments from both Isaac and Ben are a showcase for Millerbernd’s customer-oriented approach to business. But the company places an equal emphasis on those within the business. “Beginning with our CEO, Trevor Millerbernd, and extending throughout our senior leadership team, we work well together, check our egos at the door, and live out our core values,” Isaac reflects. “The result is a united set of colleagues, all of whom adopt a positive, solution-driven attitude. As a company, we do our best to repay that. Among a number of cultural evolutions in recent years, we’ve put a renewed focus on safety, and we’re proud to say that we’ve achieved a 25 percent decrease in incidents year over year.”

Comments from both Isaac and Ben are a showcase for Millerbernd’s customer-oriented approach to business. But the company places an equal emphasis on those within the business. “Beginning with our CEO, Trevor Millerbernd, and extending throughout our senior leadership team, we work well together, check our egos at the door, and live out our core values,” Isaac reflects. “The result is a united set of colleagues, all of whom adopt a positive, solution-driven attitude. As a company, we do our best to repay that. Among a number of cultural evolutions in recent years, we’ve put a renewed focus on safety, and we’re proud to say that we’ve achieved a 25 percent decrease in incidents year over year.”

Anticipating demand

From 275 employees in 2018, Millerbernd has since grown its staff contingent to approximately 470 individuals. It’s a trend that’s bolstered in part by an uptick in longevity post-pandemic, as employees put greater stock in job stability. Across the next six months, the goal at Millerbernd is to maintain its current trajectory, with a view to introducing another working shift within its transportation unit. “Our passion is proudly growing a safe and secure company,” Isaac insists. “At Millerbernd, we all believe that growth has to be healthy growth, aligned with our core markets, our manufacturing niche, and our market strategy.

“Within our DoT unit, there is strong demand,” he concludes. “A current shortage of contractors within the field is naturally causing a few delays, but there remains a large volume of available work. In light of some of the infrastructure legislation passed within the last eight months, we anticipate another strong half-decade run.”

“From our OEM business, the same is true,” Ben echoes. “Our customers have strong backlogs, and have largely emerged from the pandemic in a healthy state. The horizon is looking bright.”

www.millerbernd.com