How hydraulic cylinder manufacturer, Burnside Eurocyl, is delivering on its customer commitment

Burnside Eurocyl is a hydraulic cylinder manufacturer based in Ireland. As a leading supplier, committed to high quality and consistency, the company, as part of the Burnside Group, has been serving OEMs worldwide for 50 years. The business offers custom built cylinders to OEMs in the construction, agriculture, recycling, and automotive sectors. Over 250 experienced and qualified staff work out of a 33,000 square-meter, custom-built facility to produce only the best quality products to best-in-class production standards, customized to meet the exacting requirements of its many renowned clients.

From CNC lathes to robotic welders, its state-of-the-art production equipment is sourced and designed to produce the best quality products. With a commitment to testing, quality and safety, 100 percent of its cylinders are pressure tested. To help consolidate its position as a worldwide hydraulic cylinder manufacturer, Burnside Eurocyl has undertaken EN ISO 3834-2 certification. This standard allows the company to guarantee the highest quality in its welding processes.

From CNC lathes to robotic welders, its state-of-the-art production equipment is sourced and designed to produce the best quality products. With a commitment to testing, quality and safety, 100 percent of its cylinders are pressure tested. To help consolidate its position as a worldwide hydraulic cylinder manufacturer, Burnside Eurocyl has undertaken EN ISO 3834-2 certification. This standard allows the company to guarantee the highest quality in its welding processes.

The Burnside Group of companies was founded by the four Byrne brothers in 1974. The group operates three separate entities in the area, employing a workforce of over 1000 people. Burnside Eurocyl operates from a purpose-built facility in Carlow town in the southeast of Ireland. With customer focused production lines, the company produces over 7000 cylinders per week and delivers to key customers in Mainland Europe, North America, and Canada, as well as Australia and New Zealand.

Enhancing efficiencies

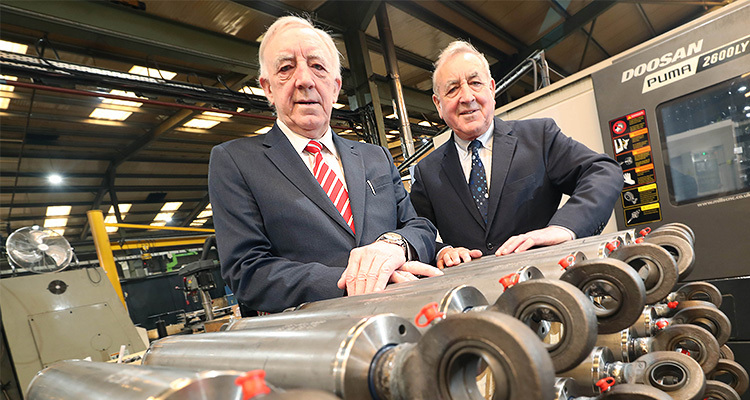

Robert Byrne, Sales Director, joins Manufacturing Today to share the company’s story. “The business made the decision in the very early days to place a particular focus on the German export market. In so doing, it enabled the company to operate in a similar way to many German companies and to focus on continual incremental change. Another key decision was to focus on world-class and lean manufacturing. Alongside this, some members of the company decided to learn to speak German. It was this combination of strategies that enabled Burnside Eurocyl to get a foot in the door of many renowned companies, such as Volvo and John Deere,” he begins.

“As a result, we adopted many of the working practices and strategies of those companies, from procurement to automation, for example. Today, this enables us to design and manufacture cylinders to the bespoke requirements of our OEM customers, on a just-in-time delivery system. Over the last few years, we have built three new production halls and invested significantly in automation for the continued success of the organization. This is to address demographic changes and cost competitive issues. We are midway through a €6 million investment plan in automation across all areas of the business, from welding, machining, and assembly to testing.

“One of the reasons for the need for automation is an issue that’s prevalent across all industries, and not just here in Ireland, but in Europe and the States too. There are currently so few people available to work in factories. It’s not that we want to reduce the number of people we employ; on the contrary, we want to maintain and increase our workforce. To grow the business, however, we need to implement automation because of that lack of available skills in the market. Right now, we’re in a cycle post-pandemic, where there’s been a big drive to reduce costs after the significant price inflation of the last few years. By increasing automation across all areas of the company, we can become more productive with the number of people we have and that will allow us to not just maintain existing business but grow our organization as well. In fact, without automation, growth won’t be achievable,” Robert elaborates. He goes on to explain that while the company’s production processes are currently highly automated, the plan now is to further enhance that level of automation with the addition of 20 new robots over the next two years, alongside expanding its production facilities.

There are currently so few people available to work in factories. It’s not that we want to reduce the number of people we employ; on the contrary, we want to maintain and increase our workforce. To grow the business, however, we need to implement automation because of that lack of available skills in the market. Right now, we’re in a cycle post-pandemic, where there’s been a big drive to reduce costs after the significant price inflation of the last few years. By increasing automation across all areas of the company, we can become more productive with the number of people we have and that will allow us to not just maintain existing business but grow our organization as well. In fact, without automation, growth won’t be achievable,” Robert elaborates. He goes on to explain that while the company’s production processes are currently highly automated, the plan now is to further enhance that level of automation with the addition of 20 new robots over the next two years, alongside expanding its production facilities.

“We’re continually working towards making lean improvements in the company,” he continues. “We’ve been collaborating with some key, international players to make all aspects of the company leaner; that’s not just on the shop floor but across all operations and including our office functions. Deloitte recognized us as one of Ireland’s Best Managed Companies and this reflects how hard the management team has been working to achieve various KPIs across finance, customer service, quality, and production. So, it’s a great independent affirmation that we’re doing something right,” he enthuses.

Quality and competitive pricing

Robert elaborates on Burnside Eurocyl’s plans for the future: “Our market development strategy is to build on the already tested and proven strategy of direct selling. As such, our plan is to grow the market by targeting a small number of companies that demonstrate product leadership and operational excellence across five segments that are a best fit for the company now and moving forward.”

With existing clients including household names like JCB as well as industry stalwarts, such as Wacker Neuson and the Wirtgen Group, the company will continue to focus on service, flexibility and value to attract and retain new partnerships. Burnside Eurocyl works hard at establishing a solid business relationship with OEMs throughout Europe, North America and further afield.

“Our plan is to continue to grow the business and be ranked among the top ten cylinder manufacturers globally. We will strive to remain a financially strong, 100 percent family-owned company that’s seen as the first choice for international OEMs who demand a high level of manufacturing quality and on time delivery. We ultimately want to retain our reputation as a competitive provider in the market. Our highly flexible manufacturing process enables us to offer consistently high levels of quality and competitive pricing. This process is strengthened by our ability to design and build specialized equipment in house, so that we can continue to service our customers, old and new, for the foreseeable future,” he concludes. ■