How innovation has driven Casso-Solar Technologies for over six decades

As Casso-Solar Technologies (Casso-Solar) approaches its 65th anniversary, President Derek Burkholder shares some highlights of the company’s rich heritage: “The business was founded in 1960 by Hugo Cahnman, who survived the Holocaust and moved to the US in search of a better life. He had the idea to design and make infrared heaters for industrial processes. Over the next ten-to-15 years the customer base grew to a decent level. Then, customers began requesting more complex equipment such as incorporating our heaters into an oven with controls.

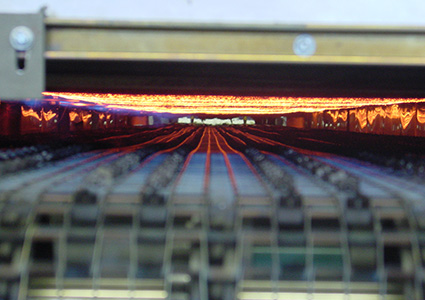

“At this time, Doug Canfield, Hugo’s nephew who would later go on to be President of the company, joined the business. He took over this part of the operation and designed equipment. They began working mostly with the textile industry, as there are many processes that require heating. In the early 1980s and 1990s demand in the textile industry started dropping so we moved into the glass industry, which is still our biggest industry, accounting for around half of our business each year.

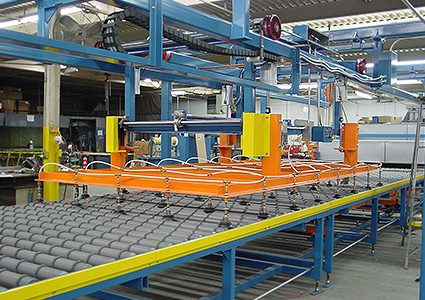

“The thing that differentiates us,” Derek continues, “is that instead of offering a standard set of products, we specialize in making more unique, tailored solutions. A customer will come to us and say: ‘Look, we have this new process we’re researching and trying to scale up’. This kind of challenge excites us. Since no one has done this type of production before, we’ll work closely with the customer to design the process, test it in our lab, provide a prototype, and refine it from there.

“For example, we recently had a company that manufactures wooden siding approach us. They char the outside layer of the wood to make it last longer and were using handheld blowtorches. As such, they wanted a more controlled, electric heating process. We worked with them to develop a specialized solution to meet their unique needs.

“We also have a good number of repeat processes, such as glass lamination lines and glass bending lines. These tend to be more standardized from customer to customer. However, we try not to pigeonhole our clients and instead work collaboratively to find the perfect solution for each one. In addition to the glass and textile industries, we also do a significant amount of work in the plastic,

metal, and food sectors.”

Optimal solutions

Derek then explains the factors that have contributed to the company’s longevity and success: “One of the things we hear time and again from our customers is that the equipment we provide works straight away and is built to last. Electric infrared heating technology typically requires little maintenance; we even have customers using equipment from the 1980s that is still operational. The long-lasting nature of our products is a major factor in the company’s longevity. Additionally, we have been deeply involved in the glass industry association, in the production of publications and have also attended the trade show for over 35 years. As a result, we have established great recognition within the sector, and most major glass manufacturers in the US have purchased our equipment at some point.”

Derek highlights how, even in an industry with a relatively stable technological base, innovation is a key contributing factor to the company’s success: “The core technology of infrared heaters themselves hasn’t changed in decades. No single company has a cutting-edge heater that others don’t also have access to. The real innovation lies in how the heater is utilized.

Derek highlights how, even in an industry with a relatively stable technological base, innovation is a key contributing factor to the company’s success: “The core technology of infrared heaters themselves hasn’t changed in decades. No single company has a cutting-edge heater that others don’t also have access to. The real innovation lies in how the heater is utilized.

“This is where our lab is especially valuable. We’ll take something we’ve never encountered before and mathematically calculate the precise amount of heat needed to achieve the desired outcome. Then it’s a matter of factoring in the customer’s desired speed, the thickness of the product, and its other dimensions. We take all this information into the lab and experiment with different combinations, such as medium-wave heaters, short-wave heaters, and various airflow levels. The key to our success is more about the innovative implementation of the heaters and being first to arrive at the optimal solution.”

Derek sheds some light on the key technologies that help make Casso-Solar’s processes so efficient: “In the last 15 years, we’ve transitioned from 2D CAD drawings to full 3D modeling for all the equipment we produce. This enables our customers to visualize not just the product itself, but also how it will fit within their existing plant.

“We’ve also recently integrated specialized software that helps us control product data much more efficiently. This, in turn, has allowed us to automate certain parts of the process – such as turning 3D models directly into manufacturing drawings. This frees up valuable time for our engineering teams to focus on other elements of product development and refinement.”

The company is seeing a growing trend of customers approaching the business in search of more sustainable alternatives to their current solutions. Derek expands: “A lot of our customers utilize convection heat processes which are often powered by propane or natural gas. These customers want to switch from gas to a more modern, sustainable, electric option. I always encourage customers to go for the electric option as it has lower upfront and maintenance costs and, because its sustainability improves as more and more of the grid’s energy is produced from renewable sources,” Derek concludes.