Digital infrastructure: a dominant factor in Keltech’s growth

By the end of 2023, Irish-based Keltech had recorded its highest ever yearly turnover, and employee headcount surpassed 250 people for the first time in the company’s history.

As a subcontractor, success depends on an ability to survey different markets, access trends (both positive and negative) and finally, assess internal capabilities to decide the best path forward.

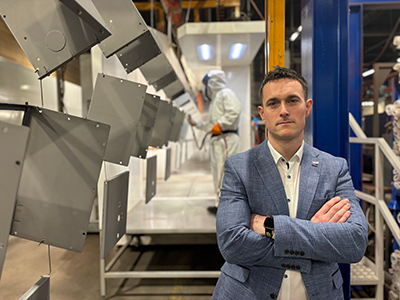

Seamus Lawlor, Keltech’s Director of Business Development, casts his mind back almost ten years to when he first began his sales career in Keltech. “Back then we had about 70 people employed, and the factory was less than half the size it is today. Our customers were predominately Irish with a sprinkling of business in the UK. Our business was heavily dependent on one to two sectors. The scary thing is if I compare the present day to our original customer base, the majority of the latter no longer exist.”

So, what is the secret sauce that has catapulted Keltech into a period of sustained growth, manufacturing plant investment, and development of its people? “I think our success has been based on our ability to survey the market, access trends and then decide the best route for Keltech.

“Our move into supplying the digital infrastructure industry is what has supercharged us. I was in a meeting with one of our blue chip diesel power generator customers and the conversation moved towards the changes in their market. They had diversified their own sales strategy and their now biggest revenue stream was providing emergency power solutions to data centers, health care and so on.

“It was probably around 2014 at this stage and the first time data centers had come across my radar. With a clear impression forming that some of Keltech’s existing portfolio of work had a short life span, it was time for the business to reinvent itself.”

Big business

Having completed market research on the digital infrastructure space, Seamus defined a clear synergy. “It took some convincing the other senior management. I think when I started talking about the cloud a good few of them started to look up,” Seamus chuckles, “however, progress was swift.”

One of the first areas Seamus targeted were critical power solution providers. “Data centers are one of the most energy-intensive building types, consuming ten to 50 times the energy per floor space of a typical commercial office building.” The vast array of products that critical power solution providers supply the industry was a perfect fit for Keltech’s capabilities. “I don’t think people realize just how huge this is; the data center industry accounts for around four percent of global electricity consumption; it’s big business.”

Performance solutions

Within 12 months of targeting the sector, Keltech had its first customer, a manufacturer of electrical switchgear and power distribution systems. “It started out small but within about 12 months they were one of our biggest customers,” Seamus recalls.

Now with a real foothold in the space, Keltech looked to expand further and supply more products into the smart economy. “We spotted some huge opportunities for investment and long-term plans happened around the rollout of full fiber broadband cables. It wasn’t too difficult to spot where Keltech could add value in this supply chain as the requirement for passive cabinets in such a deployment is pretty large. The tricky bit is getting in front of the right stakeholders. Generally speaking, once we manage that, our conversion rate is close to perfect.” A statement borne out by the small army of green cabinets Keltech produces every week now for the UK market.

“We have had further additions to our digital infrastructure customer portfolio in recent times. If I was to look at our 2023 numbers, I would be attributing close to 50 percent of our turnover to this space.”

“We have had further additions to our digital infrastructure customer portfolio in recent times. If I was to look at our 2023 numbers, I would be attributing close to 50 percent of our turnover to this space.”

So where to from here? “Innovation,” Seamus says with a grin. “It’s not about selling a product anymore; we have to sell a solution.” And true to its word, Keltech is doing just that. “One of our data storage customers came to Keltech looking for a solution. This customer, I can only describe as a technology giant, came to us looking for support. Up to this point, we have supplied an indoor product. Indoor, by its nature, is a friendly environment for painted parts, however this new product line is for outdoor environments. With weather now tending to be more extreme, this has placed an added pressure on paint performance of outdoor parts. Luckily, I’m happy to say we have an excellent solution.”

Brand protection

Keltech has just commissioned its brand-new paint facility. “One of the best in Europe,” Seamus adds. The facility is a fully automated five-stage zinc phosphate pretreatment plant, with the capability to efficiently paint parts with either a single or double-layer of powder paint. “The first thing I say to customers when it comes to paint is ‘Our Paint, Your Brand.’ What do I mean by that? Well, the components we supply are painted, the end customer is touching and feeling Keltech paint even though they don’t realize it. It’s simple. Poor paint work is brand damaging; it’s a key area of focus for us here. My advice to any customer is generally if the part is indoors, let’s choose one layer, if it’s an outdoor product, the double layer system provides parts with an added layer of protection: protecting your parts and your brand!

“2023 was a good year, we have come a long way,” Seamus concludes. “However, in our world you can never look back or even stand still for that matter. Trends and market growth that exist today might not be here tomorrow; the onus is on us to continue to display the characteristics that have got us to this point.”