How manufacturers can save on energy costs.

For manufacturers today, controlling operational costs is a constant challenge. Energy expenses often account for a large share of ongoing costs, especially as electricity rates continue to rise. This poses a significant challenge for manufacturers, often discouraging them from investing in more sustainable, energy-efficient equipment. However, making these investments upfront can lead to long-term savings in several key ways, including lower energy bills, government incentives, and reduced vulnerability to future energy price spikes. This article explores these benefits and delves into the role of LED lighting in enhancing energy efficiency.

The energy efficiency challenge

Manufacturers are constantly seeking ways to reduce operational expenses and improve sustainability. However, the initial cost of energy-efficient equipment can be a significant barrier. Despite this, the long-term benefits far outweigh the upfront costs.

Lower energy bills

Renewable energy sources like solar or wind power can greatly offset energy cost, in addition to energy-efficient equipment, particularly LED lighting, can drastically reduce energy consumption. Traditional lighting systems are notorious for their high energy use and frequent maintenance needs. In contrast, LED lights consume significantly less power and have a much longer lifespan. This translates to lower energy bills and reduced maintenance costs over time. LEDs typically last between 15,000 and 50,000 hours, significantly outlasting traditional bulbs and reducing the frequency of replacements.

Rebates and incentives

Governments worldwide are encouraging businesses to adopt energy-efficient practices through various incentives. These include rebates, tax breaks, and grants specifically designed to offset the initial investment costs. By taking advantage of these programs, manufacturers can make the switch to energy-efficient equipment more economically feasible. For example, many state and federal programs in the United States offer substantial rebates for businesses that upgrade to LED lighting.

Predictable operational expenses

Energy prices can be volatile, making it difficult for manufacturers to predict and manage their operational expenses. By investing in energy-efficient equipment, manufacturers can shield themselves from these fluctuations. LED lighting, for instance, provides consistent performance with lower energy consumption, helping to stabilize energy costs. This predictability allows manufacturers to allocate resources more effectively and plan with greater confidence.

Environmentally friendly choice

Switching to LED lighting also helps manufacturers reduce their environmental impact. With less energy consumption, facilities reduce their greenhouse gas emissions and overall carbon footprint. LEDs are also free of harmful chemicals like mercury, which is present in many HID and fluorescent lights, making them a safer option for employees and the surrounding environment.

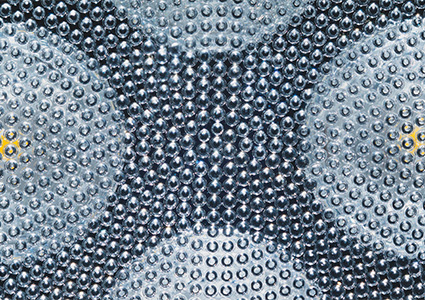

The role of LED lighting

LED lighting plays a pivotal role in the journey towards energy efficiency. For manufacturers facing pressure to reduce costs and improve sustainability, LED lighting is an effective solution. Here are some of the key benefits:

Energy efficiency: LEDs are renowned for their energy efficiency, consuming up to 80 percent less energy than traditional lighting solutions. By using high-quality LED lighting, manufacturers can drastically reduce energy use. LEDs convert most of their energy into visible light rather than heat, making them far more efficient

Longevity: LEDs have a significantly longer lifespan, reducing the need for frequent replacements and minimizing maintenance disruptions

Environmental impact: LEDs are free of toxic materials like mercury and are 100 percent recyclable, making them an environmentally friendly option

Safety: LEDs emit very little heat, reducing the risk of fire hazards in industrial settings

Versatility: LED solutions can be tailored to various industrial applications, from task lighting to high-bay lighting

In conclusion

For manufacturers today, controlling operational costs is a constant challenge, and energy expenses often account for a large share of these costs. Investing in more sustainable and energy-efficient equipment, such as LED lighting, can seem like a significant expense. However, the long-term savings and benefits far outweigh the upfront costs. From lower energy bills and reduced maintenance costs to government incentives and more predictable operational expenses, the advantages are substantial.

LED lighting plays a pivotal role in enhancing energy efficiency. Its energy-efficient nature, longevity, environmental friendliness, and safety make it an ideal choice for manufacturers looking to reduce costs and improve sustainability. With the added benefits of government rebates and incentives, making the switch to LED lighting becomes an economically feasible and environmentally responsible decision.

By adopting energy-efficient equipment and leveraging renewable energy sources, manufacturers can not only mitigate rising energy costs but also contribute to a more sustainable future. Embracing these technologies will ensure long-term success, operational stability, and a reduced environmental footprint, paving the way for a more efficient and eco-friendly manufacturing industry.

For a list of the sources used in this article, please contact the editor.

By Catherine Fuhr

Catherine Fuhr is CCO at Dialight, a global leader in improving sustainability, safety and operational efficiency for its customers by providing high-efficiency, long-lasting LED lighting technology for industrial applications. With millions of fixtures installed worldwide, Dialight’s class-leading technology reduces energy use, cost and environmental impact for customers and is certified to a broad range of international standards.