How PJD Mechanical Engineering Ltd. provides end to end solutions for the global energy market

Ropsley Ltd was formed as the holding company for the second management buyout (MBO) of PJD Mechanical Engineering. The business offers a range of repair, maintenance, manufacturing, upgrade, and new construction services to the power generation, environmental energy, and industrial process sectors in the UK.

Since then, the company has added several complementary businesses within the same service sector, including ACTTnow, HEGS PHE, Piper Services, and most recently, Green’s Power (Green’s). David Hayle, Managing Director, expands on this transitional growth: “The transition to Net Zero has accelerated the evolution of the UK’s energy mix and related industries. We have successfully transitioned the business from its traditional roots of supporting coal into gas, energy from waste, chemicals, and a whole range of sectors, primarily where steam is raised. During this time, we have expanded our services to cover a wider range of applications, while maintaining our high-quality mechanical engineering.

“In the UK, our competitive landscape is populated by two diametrically opposed types; on the one side we have established global corporations, and on the other end of the spectrum, there are small and medium enterprises (SMEs) like PJD, with very little in-between. To fill that gap in the market, we embarked upon a selective SME consolidation strategy, supported by HSBC, to develop what we consider to be a unique offering in the market.

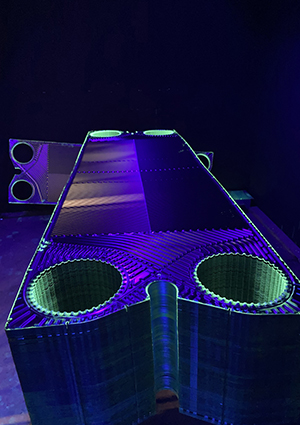

“We had been aware of Green’s for a long time, and its products have been exported to power and industrial plants all over the world. Green’s is a venerable manufacturing business with over 200 years of history, including the invention of the economizer, which converts waste heat into energy. Additionally, it felt like a very natural fit as PJD was already installing the products that Green’s manufactures. By leveraging the synergies and efficiencies within the group, we can now offer a seamless end-to-end turnkey solution to compete with major global players.”

Improving operations

David goes on: “We also have a training business, ACTTnow, with dedicated training facilities in Doncaster and Wakefield to address the core skills required to keep industry workers safe. In the UK, one of the challenges is the amount of skilled labor that will be required in the future, so we’re exceptionally proud of the fact that we are meeting our target of having ten percent of our permanent workforce enrolled in apprenticeships, and we’re continuously bringing new talent into the business.”

These recent acquisitions mean the group is on track to achieve revenues of over £40 million. “With over 250 permanent, multi-disciplined staff, we’re in a position where although the different outfits operate independently, they have the ability to come together to offer turnkey solutions whenever the need arises.”

With the addition of Green’s and its manufacturing capabilities, David explains how the group ensures its historical best practices are maintained: “In manufacturing, quality is everything, especially as the use case is so important. Post-acquisition, one of the first things we did was bring in experts to assess the facility, identify opportunities for improvement, and ensure the site could meet the demands from emerging markets. Through a combination of experienced individuals and fresh eyes, we make sure we never stand still and continually seek improvements.”

High quality manufacturing requires positive and long-term relationships with reliable supply partners. David outlines what the company looks for in its suppliers: “It’s not just the quality of the products but also the quality of service. We look for the same standards from our supply chain as we offer to our clients which is delivering projects on time and of the highest quality. We spend a lot of time auditing our suppliers to ensure not only the highest quality products but also ethical practices.”

“If we are let down by a supplier, we try and understand the root cause and what a new path would look like; we don’t throw the baby out with the bathwater. We’ll seek to help them improve if we think they can learn from us in the same way we can learn from other businesses. Saving money by using a cheaper supplier is a short-term gain that can come with collateral damage; instead, we seek longer term relationships because so many of the clients we work with have such high barriers to entry and once inside, we remain there by delivering a safe, high-quality service,” David adds.

Independent but interrelated brands

Independent but interrelated brands

Looking to the future and how the business is approaching the energy transition, David elaborates: “We are looking towards the developing markets of tomorrow, including emerging technologies like hydrogen, carbon capture, underground storage (CCUS), and small modular nuclear reactors (SMNR). It was with this in mind that we sought to acquire a company in Teesside, as that was the first net-zero hub in the UK to receive government funding. Piper Services specializes in skid mounted piping systems and indeed, fabricated the pilot CCUS plant installed in the UK for one of Europe’s largest power stations.

“By constantly assessing the technologies that will aid the transition away from fossil fuels, and developing strong connections and relationships with technology providers, we will be able to understand and meet the manufacturing demands of the future. For example: we have been working closely with a well-known global company who are developing SMNRs and now have a deeper understanding of what the group will require to participate in this supply chain. In hydrogen, we are working with several developers on pilot projects that seek to make green hydrogen a commercially viable alternative to fossil fuels.”

The group is undergoing a significant rebranding during this transition phase. “This will unify the businesses under a recognizable name that ties together the five components of the group,” David explains. “As we move forward and make further complementary acquisitions, we will have a house of brands that are independent but interrelated and able to come together when required.”

Aiming to add another two-to-three businesses to the portfolio in the next five years, David outlines the strategy: “Acquiring complementary businesses, both geographically and in terms of capabilities, will enable us to be a single, seamless source for our clients, not only those of today, but also those of tomorrow.”

Reflecting on factors that have been key to the group’s success, David concludes by emphasizing the strength of the human resources within the organization. “I’m privileged to lead an organization that is full of talent and ambition. The success of any company is always its employees, and ours is no exception being driven by the collective strength of its people. The depth of talent within our staff is what will help us stay ahead of the curve as technologies evolve. Ten years ago, many of the jobs we see today didn’t exist, so we will remain open and flexible to seize opportunities as they arise.”

The group looks to the future as it consolidates its offering to provide holistic energy production solutions. From training talent to manufacturing and servicing, the business is continually developing to stay ahead of the curve and help facilitate the energy transition. ■

Independent but interrelated brands

Independent but interrelated brands